Mobile Crusher

【Feeding Size】 <800mm

【Capacity】100-300 T/H

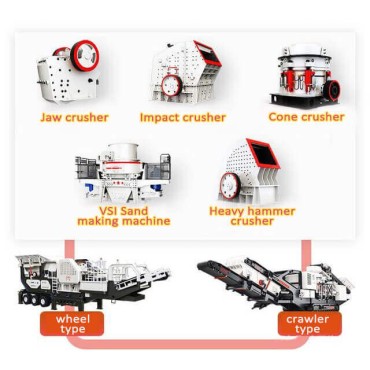

【Types of Mobile Crusher】Wheel type mobile crusher and crawler type mobile crusher

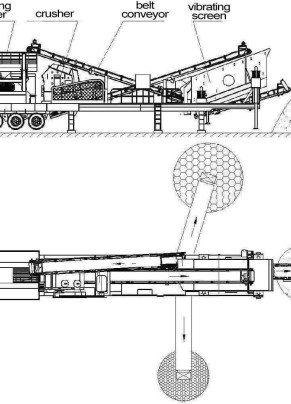

【Main Equipment】 A highly customizable combination of feeder, rock crusher, vibrating screen, conveyor, etc.

【Applications】Aggregate, quarrying, mining, construction waste recycling, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

A complete mobile breaking production line is classically equipped with a mobile jaw crusher and mobile impact crusher to achieve coarse and fine crushing operations such as stone and construction waste. Setting up the entire production line without pile driving took a few days, nearly thirty days faster than the fixed crushing production line.

The mobile crusher is mainly used for metallurgy, the chemical industry, building materials, highways, railways, and other materials that often need to be moved and processed, such as construction waste, river pebbles, granite, basalt, limestone, quartz stone, and other materials. Customers can produce materials according to the processing scale. Product quality and other requirements, select the most suitable configuration.

How to recycle construction waste with a mobile crusher? A complete set of construction waste disposal production line is composed of a mobile jaw crusher, impact crusher, vibrating screen, sand washing machine, etc., which can sort and crush construction waste and obtain a variety of high-quality sand and gravel aggregates with different specifications, widely used in roads, buildings, and other fields to achieve recycling of construction waste.

Product Structure

Mobile crusher equipment is divided into two categories: tire type and crawler type according to the bearing method. In addition, each different type of crusher can also be freely assembled according to customer needs, mainly including jaw tire mobile crushing station, impact tire mobile crushing station, cone tire mobile crusher, impact tire mobile crushing station, heavy hammer type The combination of tire mobile crushing station and crawler mobile crushing station is simple and convenient. It can effectively realize the integration of the unit and the diversity of configuration. The scope of application is more extensive and flexible.

1. The mobile crusher can be moved to the operation site to start the operation quickly, saving the construction planning time.

2. The compact structure reduces the area occupied, and is especially suitable for the small crushing site.

3. The modularized and automated operation design of the mobile crusher reduces labor costs.

4. The intelligent PLC automatic monitoring system can predict the failure of machine equipment, effectively avoiding the occurrence of major accidents.

Technical Parameters

| Portable/Mobile Jaw Crusher | ||||||

| Model | Vibrating Grizzly Feeder | Jaw Crusher | Belt Machine Specification | Capacity(T/H) | Power(kW) | Max Size(L * W * H)(mm) |

| DN938P69 | DN380×95 | PE600×900 | B800×8M | 70-150 | 91.5 | 13200×2900×4700 |

| DN1142P710 | DN420×110 | PE750×1060 | B1000×11M | 90-200 | 134 | 15000×3100×5100 |

| DN1349P129 | DN490×130 | PE900×1200 | B1200×13M | 150-300 | 146 | 17000×3300×5600 |

| Portable/Mobile Impact Crusher | ||||||

| Model | Circle Vibrating Screen | Impact Crusher | Belt Machine Specification | Capacity(T/H) | Power(kW) | Max Size (L * W * H)(mm) |

| 3YD1848F1210 | 3YD1848 | PF-1210 | B650×7M | 70-300 | 128.5-150.5 | 12500×3000×6500 |

| 3YD1860F1214 | 3YD1860 | PF-1214 | B650×8M | 90-400 | 154-190 | 13500×3000×6500 |

| 3YD2160F1315 | 3YD2160 | PF-1315 | B800×8M | 120-450 | 210-297 | 14000×3200×6800 |

| Portable/Mobile Cone Crusher | ||||||

| Model | Circle Vibrating Screen | Cone Crusher Model | Belt Machine Specification | Capacity(T/H) | Power(kW) | Max Size(L * W * H)(mm) |

| 3YD1848DN10SX | 3YD1848 | DN1000S-X | B650×7M | 70-300 | 99-134 | 13000×3000×6700 |

| 3YD1860DN12SX | 3YD1860 | DN1200S-X | B650×8M | 120-400 | 212.5-220.5 | 14000×3000×6700 |

| 3YD2160HP200 | 3YD2160 | HP200 | B800×8M | 140-450 | 257.5-264.5 | 14000×3200×6700 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.