Desliming Hopper

【Capacity】 4.5-59 m2/t

【Procesible Material】 Alluvial gold slurry, mud, sand, other minerals slurry, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Application】

Desliming Hopper, also known as cone classifier, is a simple grading, desilting, and concentration equipment, widely applied in gold, silver, copper, iron, and tungsten mineral processing. The cone classifier is mainly used to de-slime the raw ore before the hydraulic classifier to improve the classification efficiency. It is also installed in front of the grinding equipment to concentrate and dehydrate the ore to improve the ore-feeding concentration of the grinding machine. And the desliming hopper is also used in various The concentration and quantity of ore feeding should be controlled before the sludge separation equipment.

【Features】

- Simple structure

- Easy to manufacture

- Advantages such as no power consumption

- Due to the large volume of the cone, it also has the role of ore storage in the production process.

According to the different particle sizes of the material, it can be divided into ore sand deslimer type (separation of ore particles above 0.15 mm) and ore slurry deslimer type (separation of ore particles below 0.15 mm). At present, the main use of a slurry desliming hopper.

Find more classifying equipment.

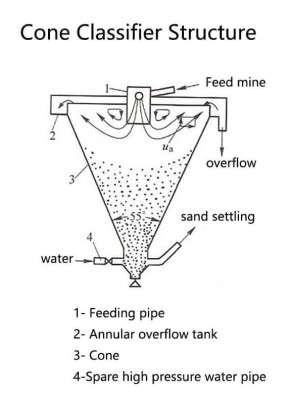

Product Structure

【Work Principle of Desliming Hopper】Desliming machine shaped like an upside-down cone. A feeder cylinder is arranged at the center of the liquid level, and the bottom edge of the cylinder falls into a number of depths below the liquid level. The slurry is fed into the central cylinder along the Tangent Direction and then flows out through the bottom edge after being buffered. The outflow of ore slurry radially flows out to the surrounding overflow Weir. In this process, the coarse particles whose settling velocity is greater than the rising fraction of the liquid flow will settle in the tank and be discharged through the bottom grit. The fine particles follow the surface slurry into the overflow tank. Feed size is generally less than 2 mm. The grading size is 75 m or more.

Technical Parameters

| Model | Subsidence Area(m2) | Volume (m3) | Discharging Tube Dia(mm) | Feeding Size(mm) | Discharging Density(%) | Capacity (m2/t) | Deslim Effective(%) | Machine size(Dia*H) (mm) |

| YX-1000 | 0.78 | 0.27 | 30 | <0.2 | 40-60 | 4.5-19 | 33-45 | 1264*1529 |

| YX-1500 | 2 | 0.83 | 40 | <0.2 | 40-60 | 4.5-25 | 33-45 | 1804*2115 |

| YX-2000 | 3 | 2.27 | 50 | <0.2 | 40-60 | 4.5-35 | 33-45 | 2404*2715 |

| YX-2500 | 4.9 | 4 | 60 | <0.2 | 40-60 | 4.5-45 | 33-45 | 2906*3328 |

| YX-3000 | 7 | 6.65 | 70 | <0.2 | 40-60 | 4.5-59 | 33-45 | 3406*3925 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.