Coltan Ore Introduction

Coltan mining has an incompatible role in the mining industry, coltan is widely used in the manufacture of high-tech products, such as mobile phones, DVD players, PS2 Games and so on.

Tantalum-niobium ores are for include tantalum and niobium, When have most tantalum call tantalite, when have most niobium call niobite. It has alluvial tantalum-niobium ores and stone tantalum-niobium ores.

Coltan Mining Process Flow

Feeding: have various kinds of feeding way, depends on the plant and material conditions, have choices of vibration feeder, hopper, belt feeder, or wheel loader and excavator feed directly.

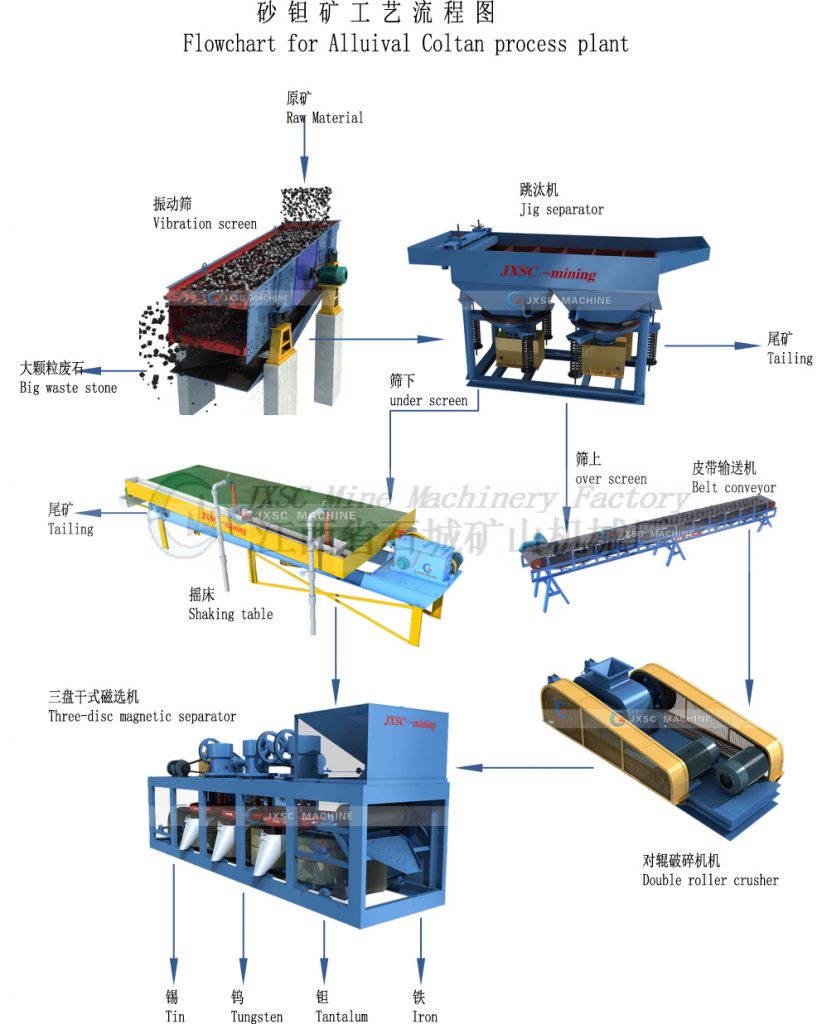

Sieving: this process is for vibration screen sample washing and screen different size. Vibration screen can add high-pressure water, So can washing sample, the screen can get two sizes, big size to cone crusher, small size to jig separator.

Crusher: Cone crusher output size is smaller than jaw crusher, hammer crusher, cone crusher output size also needs a feeder to jig separator.

Jig separator: It has two way for feeding, one after vibration screen separator small size, and after cone crusher output size. Jig separator also has two way get concentration, one for up of screen get concentration, one for under of screen get concentration.

Shaking table: Shaking table is for final concentration, after jig separator, then go shaking table. The shaking table is to improve the content, sometimes if don’t need high content can don’t use shaking table

The most effective process flowchart and most suitable process equipment are always recommended as per customer’s request and tantalum-niobium ore conditions and process capacity.

JXSC mine machinery has more than 35 years of experience in the mining industry, our coltan mining equipment is very popular in Africa( like Congo, South Africa, Ethiopia).