JXSC has designed a complete set Flowchart and provides a complete set of processing plant machines &all accessories for Uganda customer RockStone Tin Processing Plant in Uganda. The client has their engineer team for setting up this plant, so no requirement for our engineer site service. While we offer a detailed layout design with base construction drawings accordingly.

5TPH Trial Rock Stone Tin Plant in Uganda

Published Date:28 April 2023Client’s Mine Situation

- The rock stone needs to crush less than 5mm to release the inside tin. The Tin granularity size ranges from 2-5mm.

- The client owns this mining land in Uganda.

- The 5tph is just a start. Next year, I will set up a big rock tin plant and an alluvial tin plant.

Rock Tin Mining Equipment

- Trough feeder

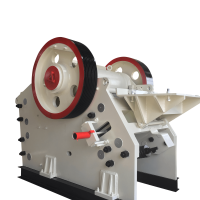

- Jaw crusher

- Belt conveyor

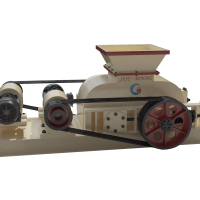

- Roller crusher

- Vibrating screen

- Jig machine

- Dewatering screen

- Shaking table

- Slurry pump

- Water pump

5TPH Rock Tin Plant Video

Video Description

- This is a trial Rock Tin plant, The big stone is crushed smaller by hand. And before feeding into the raw ore hopper, you can use the electronic weighing machine for weighing the raw stone input feeding.Feeding the stone ore into a hopper by manual or small wheel loader.

- Under the hopper, a conveyor belt transports the stone to the next crushing part.

- There is a smaller hopper above the jaw crusher machine, under the hopper, there is a chute feeder to feed the stone into the jaw crusher more evenly and smoothly.

- The output from the jaw crusher is kind of very small already. Then I will go to a vibrating screen for the screening here. The bigger than 5mm gravel sand will go to the next double roller crusher by belt conveyor. Smaller than 5mm goes to another belt conveyor and feeds into a jig machine.

- The roller crusher crushes the gravel sand size fine gravel smaller into 5mm. The output will be transported to a vibrating screen for screening again. So here the crushing part is a closed loop to ensure all the output sizes are fine enough before beneficiation.

- The jig machine for enriching the tin concentrate. Tanks will collect the <2mm concentrate under the jig screen.

- The shaking table for fine tin separation. Which can improve the upgrade.

- The client requires a dewatering screen and needs to recycle the tailings water from the jig separator. The waste sand after dewatering, will then be transported away by the belt conveyor.

JXSC is a professional mining equipment manufacturer & mining ore solution expert, it has many successful cases such as gold plants, diamond solutions, etc., If you need such a service please contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.