25TPH Chromite Ore Concentrating Plant in South Africa

Published Date:18 June 2019Description of the chromite mine

Project: extraction of chromium from its ore

Country: South Africa

Mineral type: chromite ore

Capacity: 25TPH

Mineral property: Grade of chrome concentrate in raw chromite ore is 28% – 36%.

Customers requirement: The grade of the processed chromium concentrate needs to be 42% – 45%

Feed particle size: 150mm

Required mining machines in the complete chrome beneficiation plant

| Equipment name | Model | Qty (set) |

| Jaw crusher | 500*750 | 1 |

| Belt conveyor | 500*10,000mm | 1 |

| Jaw crusher | 250*1000 | 1 |

| Belt conveyor | 500*15,000mm | 1 |

| Jig feeder | 600*600 | 1 |

| Ball mill | 2100*3600 | 1 |

| Spiral Classifier | 1500*8000 | 1 |

| Mixer | 2000 | 2 |

| Slurry pump | / | 1 |

| Spiral chute | 1200 | 12 |

| Shaking table | 6-S | 10 |

| Grinding balls for ball mill | / | 20 ton |

| Motor controls | / | 1 |

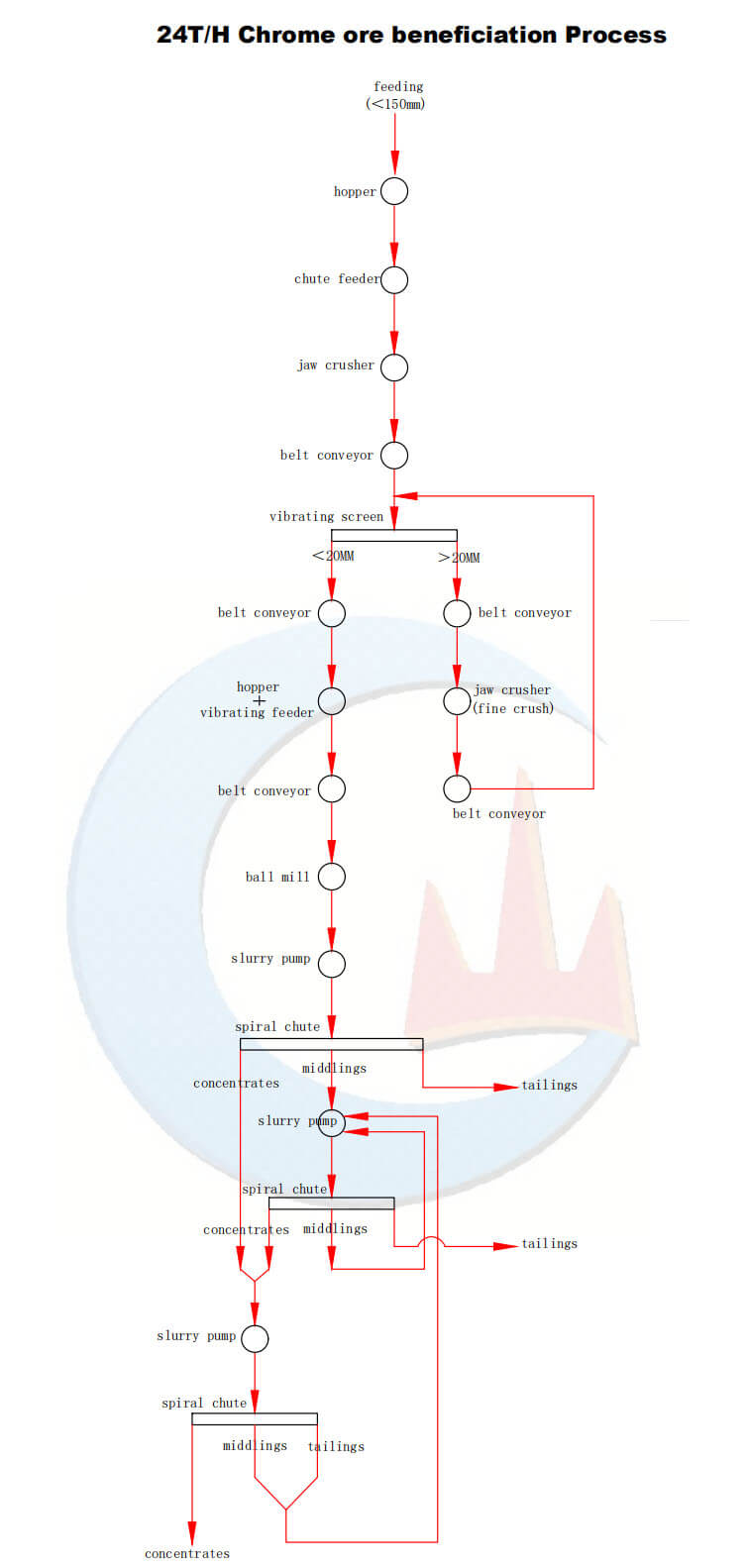

Chrome beneficiation plant flow diagram

Click to download the PDF file of 25TPH Chromite ore concentrating plant flow diagram pdf

Chromite crushing

The large blocks of Chrome ore are initially crushed in a jaw crusher, may further finely be processed in a cone crusher, and the next, they are separated into different particle sizes by a vibrating screen. the large size ore material (larger than 20mm) enters into the fine jaw crusher to be broken again.

The chromite crushing section is consists of an ore bin, coarse ore grizzly feeder, pan feeder to the crusher, and a discharge belt conveyor. How to choose the mineral material feeder in the mining industry?

Chromite grinding classification

The vibrating feeder can feed the crushed ore into the grinding machine evenly and accurately. Before the material into the ball mill, the plus 20mm Chrome ores are separated by the vibrating screen, and the ground ore is then conveyed to the jig separators.

Gravity separation

Chromite mining methods

Latinum groups (platinum, palladium, iridium, osmium, and rhodium), cobalt, titanium, vanadium, nickel and other elements are often associated with chromium deposits.

(1) gravity separation: such as Jig, shaking table, spiral separator groove, heavy medium cyclone, etc.

(2) magnetic-electric separation: including high-intensity magnetic separation and high-voltage electric separation.

(3) flotation and flocculation flotation.

(4) combination: such as gravity separation.

(5) chemical beneficiation: Treatment of very fine refractory lean chromium ore.

Practice shows that the chromite ores are concentrated to the best by using the gravity separation method.

How much does it cost to invest in a chrome ore processing line?

It is affected by various factors, includes equipment configuration, production requirements, supplier determination, and so on. It is certain that the choice of JXSC is the best to minimum investment, and maximum profits, advantages of complete types and models, excellent quality and performance, credible fame, experienced engineer team, professional solutions, caring service and competitive price. The cost of investment of mineral processing plants can be cheaper than others at quite a sum.

Are you facing the difficulty of choosing a mining equipment manufacturer? JXSC could be the answer, contact us.

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.