Plate Magnetic Separator

【Capacity】8-35 t/h

【Power】1.5-3 kW

【Application Materials】Limonite, hematite, ilmenite, garnet, carborundum, etc.,

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The plate high gradient magnetic separator is mainly suitable for the magnetic separation of weakly magnetic minerals with a particle size of less than 5MM and the iron removal of non-metallic minerals, such as mica powder, quartz sand, potassium feldspar, nepheline, fluorite, sillimanite, Spodumene, kaolin, manganese ore, weak magnetite, pyrrhotite, roasted ore, ilmenite, hematite, limonite, siderite, ilmenite, chromite, wolframite, da Silver ore, red mud, etc. It can also be used for iron removal operations in coal, non-metallic minerals, building materials, and other materials. This product is our latest research and development of high gradient and high-intensity magnetic separation equipment. It has the advantages of a high magnetic field, low energy consumption, simple and convenient debugging, and few wearing parts.

Features

- Reasonable magnetic field distribution

The magnetic field intensity is large, the magnetic gradient is high, and it has high processing capabilities. - Magnetic system with large corner design

Computer design simulates the magnetic circuit, with no empty magnetic areas and uniform magnetic field distribution. - Automatic iron unloading has a low failure rate

Automatic iron unloading ensures long-term trouble-free operation. - Fully sealed bearing seat with good sealing performance

Simple structure and easy maintenance. It has less noise, lower energy consumption, and low cost of use.

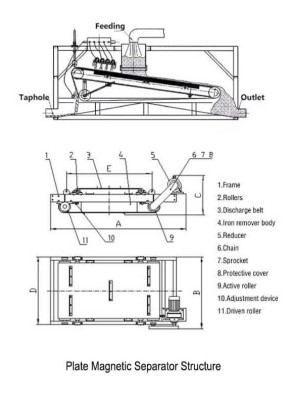

Product Structure

Plate type high gradient magnetic separator consists of a frame, plate-type magnetic system, feed mixing system, water system, iron unloading system, and regulatory system.

When working, the material flow and unloading system is in a reverse counterflow. According to the physical structure principle, the non-magnetic material flows to the discharging port to achieve a complete unloading purpose by washing. The magnetic material is attracted by strong magnets for long distances, wide areas, and multiply-frequency, and be taken to tapping hole in reverse running by unloading system, then to achieve complete unloading purpose by washing.

Technical Parameters

| Model | Width (mm) | Length (mm) | Capacity (t/h) | Power (kW) | Dimensions (mm) | Weight (t) |

| 600×2000 | 600 | 2000 | 8-10 | 1.5 | 4000x1000x1800 | 2.4 |

| 800×2000 | 800 | 2000 | 10-13 | 1.5 | 4000x1200x1800 | 2.6 |

| 1000×2000 | 1000 | 2000 | 13-18 | 1.5 | 4000x1200x1800 | 2.8 |

| 1200×2500 | 1200 | 2500 | 18-25 | 1.5 | 4500x1600x1800 | 3 |

| 1500×2500 | 1500 | 2500 | 25-30 | 2.2 | 4800x1900x1800 | 3.5 |

| 2000×2000 | 2000 | 2000 | 30-35 | 3 | 4000x2400x1800 | 3.8 |

| 2000×2500 | 2000 | 2500 | 30-35 | 2.2 | 4800x2400x1800 | 4 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.