JXSC has provided a successful 300TPD(12TPH) rock gold CIP processing plant in Kenya. We design the CIP gold plant process flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance. Make this gold CIP project installed successfully and satisfied with the customer.

300TPD(12TPH) Rock Gold CIP Processing Plant in Kenya

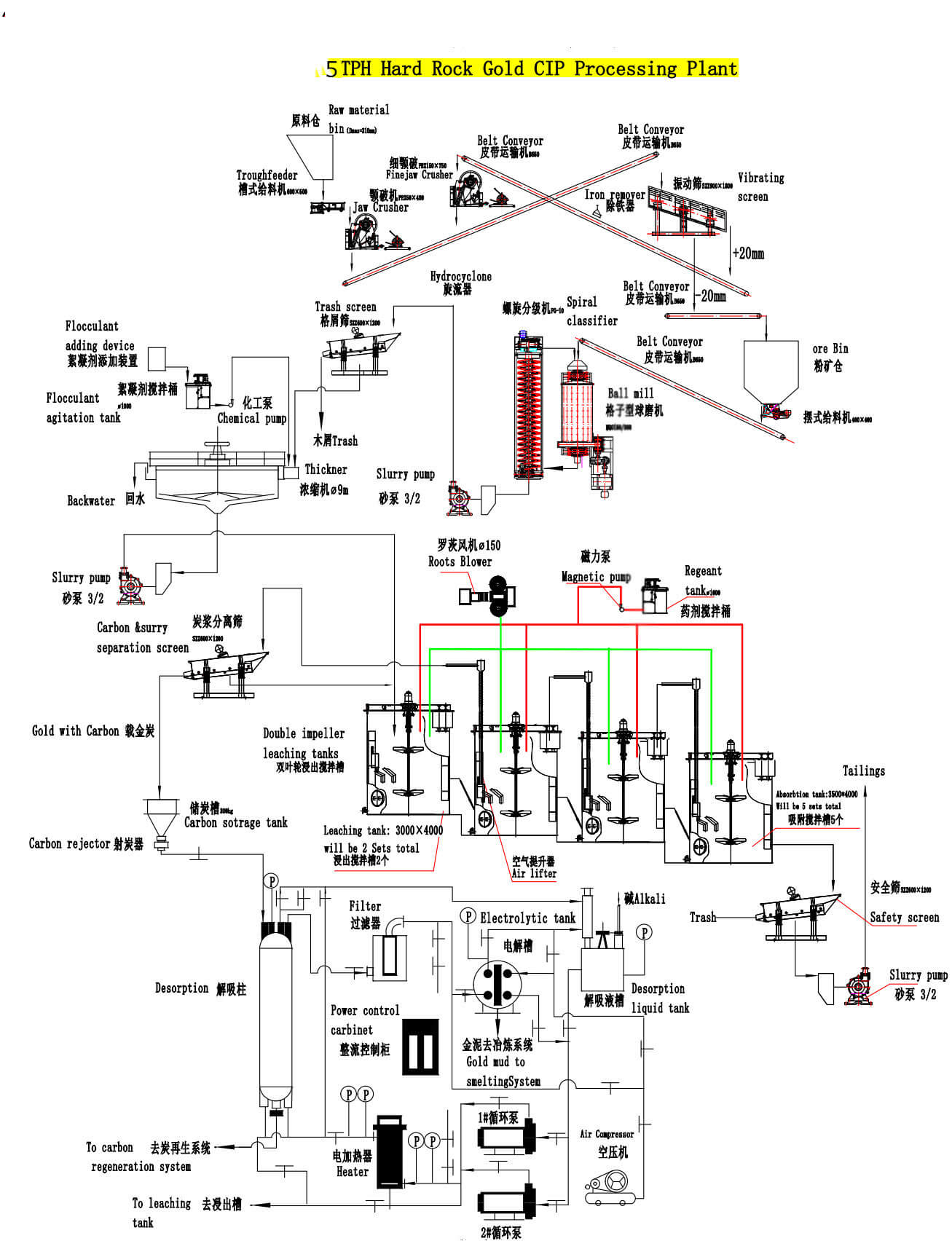

Published Date:02 November 2021300TPD(12TPH) Rock Gold CIP Processing Plant Flowchart

Gold CIP Mining Equipment

This complete CIP gold process plant includes a feeding machine, jaw crushers, fine jaw crusher, belt conveyor, vibration screen, ball mill, thickener, leaching & adsorption agitation tanks, desorption electrolysis system, tailing water recycle system, and all the other needed accessories.

Flowchat Description

The crushing plant is for crushing big rocks to a smaller size(0-20mm), then feeding to ball mill grinding to 200 mesh, then make 200 mesh slurry material to suitable pulp concentration by thickener. Concentrate ore from thickener will go to leaching tanks and adsorption agitation tanks and put activated carbon in adsorption tanks to absorb gold.

After eluting the gold-loaded carbon, the precious liquid enters the desorption electrolysis equipment to enrich the gold mud. After drying the gold mud, smelt it into gold bars.

The Gold CIP plant has a very high recovery ratio for oxide & sulfide type gold. It is currently an internationally popular gold beneficiation technology, also the trend of gold beneficiation development.

MQZ1836 Ball Mill Used in This Case

JXSC Ball Mill is Widely Used in the Rock Gold Processing plant for grinding rock to very fine powder 200mesh or 0-1mm. This Video is ball mill Model MQZ1836 applied in our Kenya Customer’s 300TPD Gold Tailing Material CIP Processing Plant.

For this project, the Feeding size of gold tailing material to the ball mill is 0-3mm, output size needs to reach 85% 200mesh by using Hydrocyclone or Spiral Classifier work together. So based on this feeding size and output size, the processing capacity of this model can reach About 12TPH. If bigger feeding size (10-20mm), process capacity reaches about 8-10TPH. The exact process capacity depends on inpu&output size.

MQZ1836 Ball Mill main Specifications:

- Drum Size: 1800*3600mm (Dia*L)

- Power: 155KW

- Rotary Speed: 25.2-27RPM

- Reduction Ratio: 3.55

- Machine weight: 32Tons

This Complete set Ball Mill is including those machine parts:

- Rotary Drum

- Wear-resistant Lining Plates inside the drum

- Motor&Reducer

- Big&Small Gears

- Coupler&Bearing&Bearing seat&Bearing cover

- Frame& Frame for driving part

- Feeding device&feeding screw

We also provide The ball mill work-related devices electric control cabinet and steel ball, for MQZ1836 ball mill, generally need 11 tons steel balls.

The Ball mill Grinding Machine also can be used to grind many other rock minerals, such as Coltan, Tin, Tungsten, Copper, Iron, Manganese ore, Quartz, Chrome, Zinc, Lead, Fluorite Ore, etc.

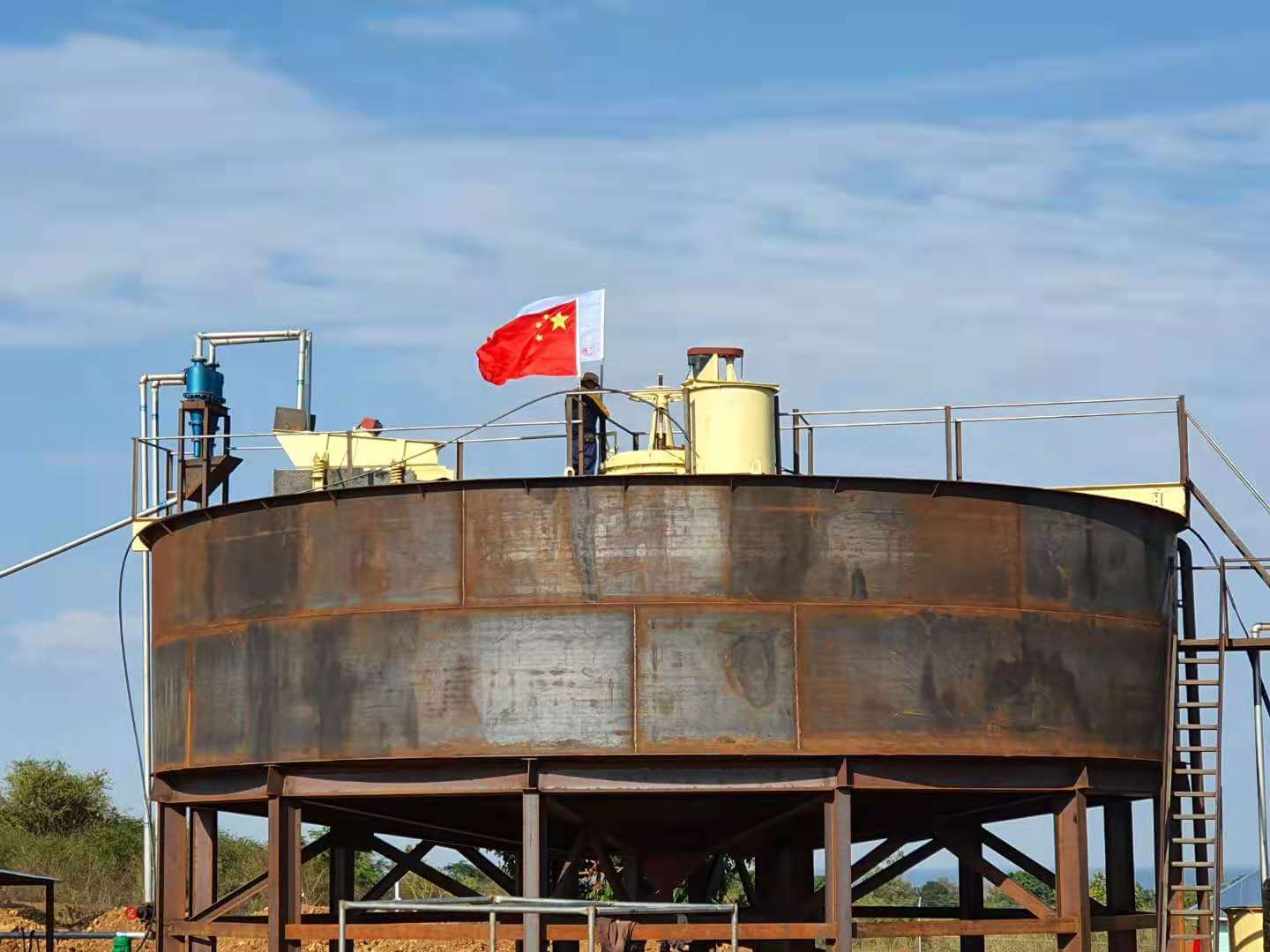

On-site Installation

JXSC is a professional mining equipment manufacturer & mining ore solution expert,it has many successful cases such as small/mobile CIP gold plants, diamond solutions, etc., If you need such service please contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.