Tubular Screw Conveyor

【Capacity】6-50 m3/h

【Procesible Material】 Fly ash, cement, building materials, chemical raw materials, pulverized coal, grain, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The tubular screw conveyor (also called single-tube screw feeder) provides horizontal and inclined feeding equipment for fly ash, cement, building materials, chemical raw materials, coal powder, grain, and other media. It can be customized according to the feeding volume, conveying distance, and other usage requirements. It is suitable for dry powder and small particle materials, it has the characteristics of a good sealing effect, uniform and stable feeding, long service life, simple operation and maintenance, etc. It is a widely used feeding equipment.

The tubular screw conveyor is continuous and uniform feeding equipment for raw materials made of carbon steel, manganese steel, stainless steel, and other materials. It is designed and manufactured according to the spiral diameter, length of the inlet and outlet, feeding inclination angle, and feeding amount. It is equipped with 4-level, 6-level, variable frequency speed regulation or electromagnetic speed regulation motors to achieve timing and quantitative controllable feeding during the continuous feeding process. It is suitable for different working conditions and usage environments.

The feeding length and feeding volume of the tubular screw feeder can be designed and produced according to actual needs. When the feeding distance is short, a single section is used. When the feeding distance is long, a multi-section connection is used. The middle shell is connected with flange bolts. The main shafts are connected by internal and external splines that are extremely simple to install. At the same time, the feeding amount can be controlled by changing the diameter of the spiral pipe and the speed of the impeller.

Features

- Suitable for conveying

Tubular screw conveyors are suitable for conveying materials that are not easy to deteriorate, are highly viscous, and are easy to agglomerate. In concrete mixing stations, the role of screw conveyors is reflected. - Easy to maintain

The spiral shaft, hanging bearing, head, and tail shaft are all connected by embedded tongue type, which does not require axial movement for installation and disassembly. It is easy to maintain, has a long mandrel, and requires less hanging. - Not easy to jam

Each transmission part adopts a floating connection method, which can freely rotate and avoid according to the conveying resistance within a certain range, without jamming or clogging of materials. - Long life

The variable diameter structure is adopted to increase the volume of the hanging bearing and avoid contact between the hanging bearing and the material. The life of the hanging bearing can reach more than two years.

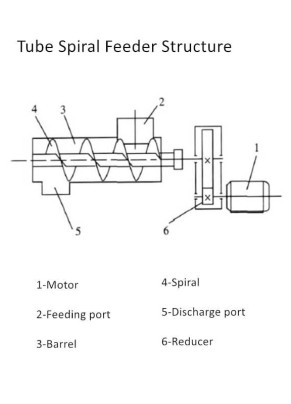

Product Structure

The tubular screw conveyor/feeder is a feeding equipment composed of a motor, a reducer, a circular shell, a rotary blade, and a spiral spindle.

The tubular screw conveyoris driven by a motor and a reducer to rotate the main shaft. At the same time, the rotating blades hovering on the main shaft follow the passive rotation. The powder falls from the feed port into the country-shaped shell and lands in the gap between the spiral blades, using the action of centrifugal force and friction to push the powder forward and discharge it from the shell at the discharge port to complete the entire feeding process.

Technical Parameters

| Model | Spiral Diameter (mm) | Spiral Pitch (mm) | Feeding Capacity (m3/h) | Spiral Speed (r/min) | Motor Power (kW) | Weigh (kg) | Remark |

| 100 | 100 | 1200 | 6 | 34 | 2.2 | 459 | Single Spiral |

| 160 | 160 | 28000 | 21.3 | 59 | 11 | 3329 | |

| 200 | 200 | 1500 | 30 | 43 | 5.5 | 629 | |

| 250 | 250 | 3000 | 30 | 43 | 5.5 | 881 | |

| 315 | 315 | 4000 | 45 | 43 | 5.5 | 1316 | Double Spirals |

| 400 | 400 | 3000 | 50 | 43 | 5.5 | 1439 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.