Three discs high intensity dry magnetic separator is a dry type magnetic adjustable separating machine, special for separation minerals such as coltan, tungsten, tantalite, cassiterite, wolframite, ilmenite, rare earth ore, chromite, limonite, columbium and tantalum ores, zircon, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic differences and removal of iron in nonmetallic minerals.

You may interest in

1. How to class Magnetic Minerals?

2. How Many Types of Magnetic Separators?

3. What mining magnetic separators we provide?

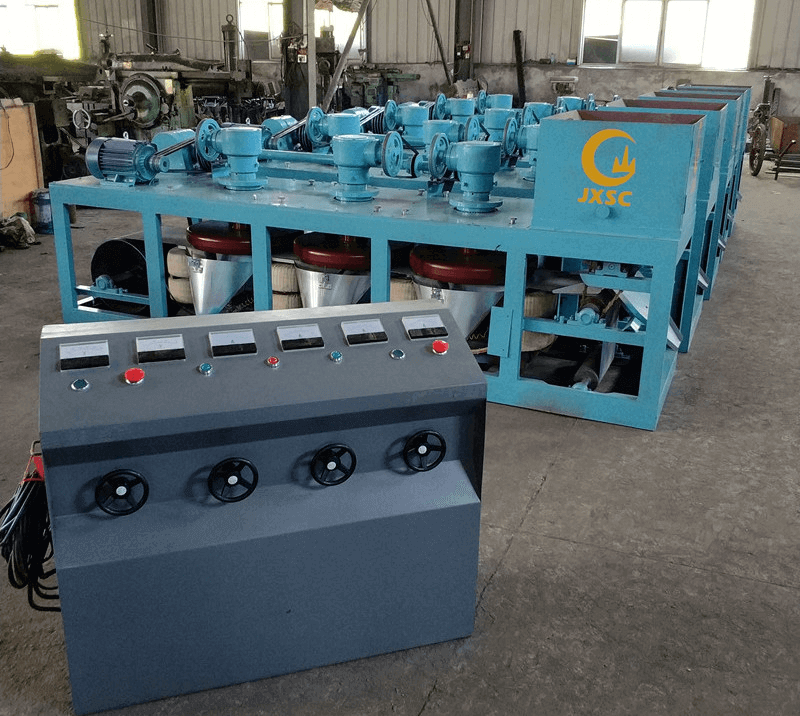

3pc high intensity dry magnetic separator consists of four electric magnetic coils, three magnet discs, and under the feeding hopper, there’s a small low-intensity magnetic drum, which is used for remove iron sand or other high magnetic intensity minerals. The electric control cabinet section consists of components of control, voltage regulation, rectification, instrument and so on.

The disc belt magnetic separator consists of a single belt upon which the feed is distributed across and is transported slowly underneath a series of four electromagnets, the magnetic fields of which lift the magnetic grains off the belt depending on their susceptibility. Underneath each magnet is a smaller faster moving belt across the main belt at right angles which picks up the magnetic grains and transports them away from the magnetic field to discharge into launders. The gap between the main belt and the magnets becomes progressively smaller until only the non-magnetic grains unaffected by the magnetic fields remain on the main belt and discharge off the end.

Three-disc electromagnetic separator is for a variety of strong magnetic minerals mixed ore separation, according to the difference of magnetic minerals, can achieving efficient separation of minerals can form different intensity magnetic disk by adjusting the excitation current levels, can also be adjusted each level disk and sensing distance between dressing grain is to get different magnetic induction intensity, reaching a one-time separation of various minerals. This device is widely used in ilmenite, monazite, tungsten, tin, tantalum, iron ore and other minerals with magnetic and non-magnetic dry sorting.

The magnetic separator machine can get an extremely high separating efficiency, which could get 4 kinds of high-grade minerals to concentrate at one time. Operations can be adapted to water-lack mines, which is very popular in the unwatered areas.

The three-disc electromagnetic separator is sorting mineral with size less than 2-3mm of weakly magnetic minerals and rare metal ore selection, The moisture of the feeding material should be under 1%.

it is a very important mineral processing equipment. Three-disc electromagnetic separator have 2 models: 3PC-500 & 3PC-600, 3PC-500 with magnetic disc diameter of 500mm, while model 3PC-600 is with disc diameter 600mm.

1. This belt magnetic separator could separate four different useful minerals at one time.

2. 4 varieties of final concentrate can be obtained by separation of this Dry Intensified Magnetic Separator.

3. Ta & Nb grade could reach 60% by using our dry magnetic separator.

4. compact structure, stable performance, easy installation, and convenient operation and maintenance.

5. magnetic intensity can be adjustable, also can be used for other mineral concentrations.

In December of 2017, JXSC delivered 5 sets 3pc disk dry magnetic separator to Nigeria, for tin processing.

3pc disk dry magnetic separator is a dry intensified magnetic separator, special designed for separation of ilmenite, rare earth ore, chromite, tungsten and tin ores, limonite, columbium and tantalum ores, zircon, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic differences or removal of iron in nonmetallic minerals.

— very high magnetic field intensity 16000gauss – 20000gauss

— it can separate 4 final concentrate in one time.

— Ta & Nb grade can reach 60% by using this separator.

— it’s easy to install, adjust, and operate.

JXSC establish a professional mineral laboratory for sample testing from 2017, we can do magnetic separation test of sample ores for gold, tin, tungsten, chromite, tantalum-niobium, tantalite, ilmenite, limonite, magnetite, and other magnetic mineral’s test. Welcome to send your sample ores for our analysis.