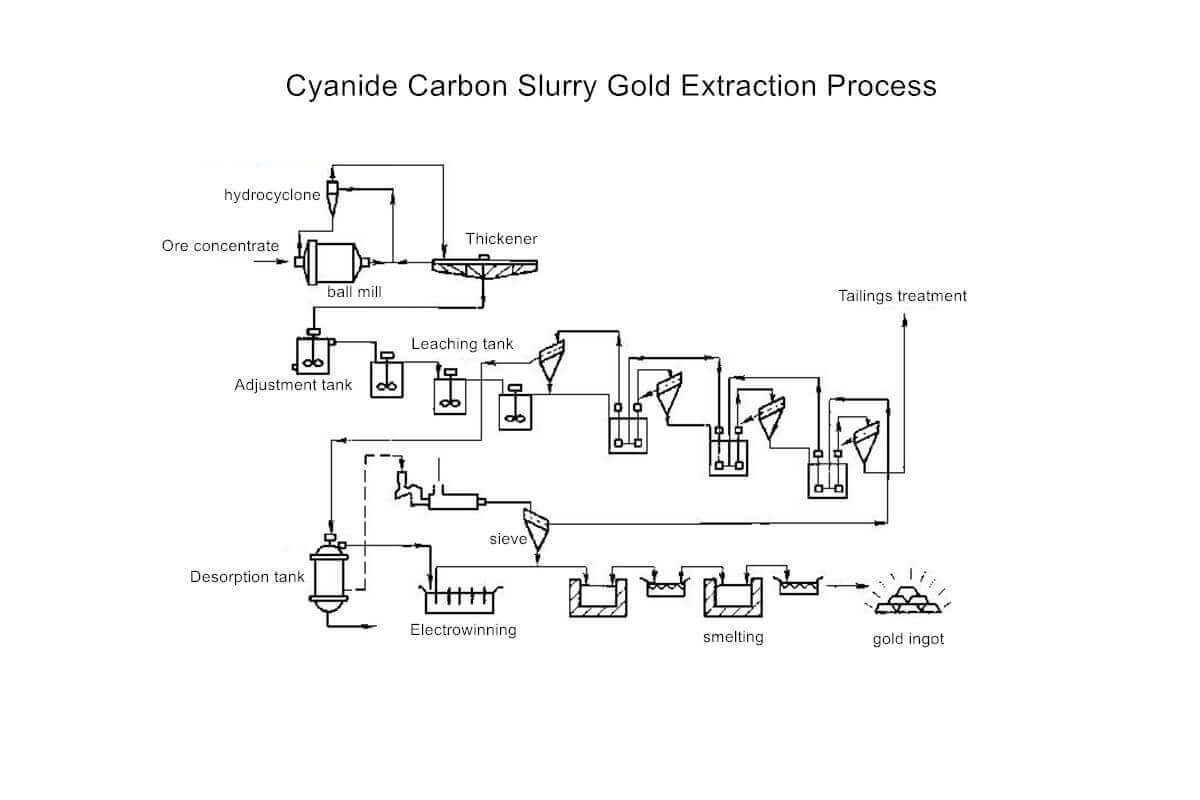

The cyanide carbon slurry method is a common process for extracting gold, also known as the cyanide gold extraction method. The following is its process flow:

Gold Extraction Process by Cyanide Carbon

1. Raw material preparation

Gold-containing materials undergo crushing, grinding, and classification operations to grind the materials to a particle size suitable for cyanidation, generally -200 mesh 80-90%, and remove impurities such as sawdust, and then use a thickener to concentrate and dehydrate to increase the concentration of the pulp to 40-42%, and then enter the leaching operation.

2. Stir cyanide leaching

The cyanide slurry enters the stirred adsorption tank (carbon slurry tank), the same as the conventional cyanidation method. Generally, there are 5 to 8 double-impeller stirred leaching tanks. Add lime and sodium cyanide and introduce compressed air into the tank for leaching and adsorption. The leaching time is generally 24 to 48 hours, of which the first two tanks are pre-soaked, and the next 4 to 6 tanks are used for leaching and adsorption.

The adsorption tank is equipped with a carbon screen and a slurry lifter, which realizes the reverse flow of activated carbon and slurry, lifts the activated carbon out of the first adsorption tank, and flows to the desorption electrolysis operation for desorption and electrolysis of activated carbon.

3. Activated carbon countercurrent adsorption

After cyanide leaching, the slurry is stirred and enters the activated carbon slurry countercurrent adsorption circuit. The adsorption system generally consists of 4-6 activated carbon adsorption tanks, and the countercurrent flow of slurry and activated carbon is achieved through air lifters and inter-tank screens. At this time, still blow air in and add milk of lime and cyanide, but no cyanide is added to the last 1-2 adsorption tanks to reduce the cyanide content in the depleted slurry. The initial inter-trough screen of the carbon slurry process mainly used a vibrating screen with a large amount of carbon wear. The inter-tank screens in the carbon slurry process mainly use fixed peripheral screens, bridge screens, or submerged screens. The screened slurry returns to the wooden tank and sends the activated carbon to the previous tank. Add regenerated or new carbon to the last tank of the adsorption tank, and regularly transfer the gold-loaded carbon from the first adsorption tank to the gold-loaded carbon desorption system for gold desorption and activated carbon regeneration. The remaining tail slurry is inspected and screened (the mesh size is 0.701 mm) to recover the lost gold-loaded fine-grained carbon and then sent to the tail slurry treatment process.

4. Gold-loaded carbon desorption electrolysis

Desorption of gold-loaded carbon: After removing wood chips and sludge, the carbon is sent to a desorption column for gold and silver desorption. Currently, four methods can be used to desorb gold-loaded carbon in production:

- Zadra method: This famous method was invented by Zadra in the United States in 1952. This method uses 85-95X hot 1% NaOH and 0.1% ~ 0.2% NaCN mixture to pass through two desorption columns sequentially from bottom to top under normal pressure, and the noble solution obtained by desorption is sent to the electroplating of gold and silver. After electroplating, the de-gold solution (poor solution) is returned to the No. 1 desorption column, and the desorption time is about 40-72 hours. When the Homestake Gold Concentrator in the United States uses this method to desorb gold-loaded carbon with a gold loading of 9 kg/ton, the desorption time is 50 hours, and the residual gold content in the carbon is 150 g/ton of carbon. This method suits gold dressing plants with small processing capacities and low equipment and production costs investment.

- Organic solvent method: A method invented by Haining of the US Bureau of Mines, also known as the alcohol desorption method. Use a hot solution (80P) of 10%-20% alcohol, 1% NaOH + 0.1% NaCN for desorption. The operation is performed under normal pressure, with 5 to 6 hours of desorption. Heating and reactivation of activated carbon can be performed once every 20 cycles. The disadvantage of this method is that alcohol is volatile, toxic, flammable, and explosive, and a good condensation system needs to be equipped to capture alcohol vapor to prevent fire and explosion accidents. The above shortcomings limit the promotion and application of this method.

- High-pressure method: The high-pressure method is invented by Porter of the U.S. Bureau of Mines. It uses 1% NaOH and 0.INaCN solution for desorption under 160P and 354.64 kPa (3.5 atmospheres), and the desorption time is 2 to 6 hours. The disadvantage of this method is that it requires high temperature and pressure, and the equipment cost is high. The advantage is that it can reduce desorption time, chemical consumption, and carbon storage amount. This method suits gold processing plants with large capacities and high gold loading on activated carbon.

- South African Anglo-American Company Law (A.R.R. L Law): This law was proposed by Davidson of the Anglo-American Research Laboratory in Johannesburg, South Africa. It uses 0.5% to 1% carbon volume of heat and 10% NaOH solution (or 5% NaCN + 2% NaOH solution) in the desorption column for 2 to 6 hours and then uses 5 to 7 carbon volumes of hot water. The eluent flow rate for elution is three carbon volumes per hour, and the total desorption time is 9 to 20 hours. Its advantages are similar to the high-pressure desorption method but require multi-channel liquid flow equipment, increasing the system’s complexity.

The noble liquid obtained by desorption of the gold-loaded carbon is sent to the electrostatic deposition gold or zinc powder to replace the sedimentary gold, and the activated carbon is sent to the carbon regeneration operation.

Desorption electrolysis methods include average temperature, standard pressure, and high-temperature and high-pressure desorption methods. Among them, high-temperature and high-pressure electrolysis have high desorption and electrolysis rates, a high degree of automation, and a short operating time. It does not use sodium cyanide, so customers deeply love it.

5. Gold and silver smelting

Gold and silver smelting is to smelt electrolyzed gold mud into finished gold. The grade can reach 99%~99.99%. The process can be pyrometallurgy or hydrometallurgy.

2-5Kg High-Frequency Gold Melting Furnace

6. Activated carbon recycling

During the adsorption process of carbon slurry, activated carbon not only adsorbs dissolved gold and silver but also adsorbs various inorganic and organic substances. These substances cannot be removed during the desorption process of gold and silver, causing the carbon to be contaminated and reducing its adsorption activity. Therefore, the desorption carbon must be regenerated before returning to the adsorption system to restore its adsorption activity for dissolved gold and silver.

The regeneration methods of desorption carbon are pickling and fire. The pickling method uses dilute hydrochloric acid or dilute nitric acid (concentration is generally 5%) to wash the desorption carbon at room temperature. We often carry out the operation in a separate stirring tank; at this time, we can remove calcium carbonate and most base metal complexes. The pickled carbon must be neutralized with alkali and washed with water before being sent for fire regeneration. Fire regeneration uses a regeneration kiln for heating. To more thoroughly remove adsorbed inorganic and organic impurities that cannot be removed by desorption and pickling, most gold dressing plants regularly send the desorbed carbon after pickling, alkali neutralization, and water washing into an indirectly heated rotary kiln. Heat 600~800℃ in isolation from air, keep the temperature constant for 30 minutes, and then cool in the air or quench with water.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…