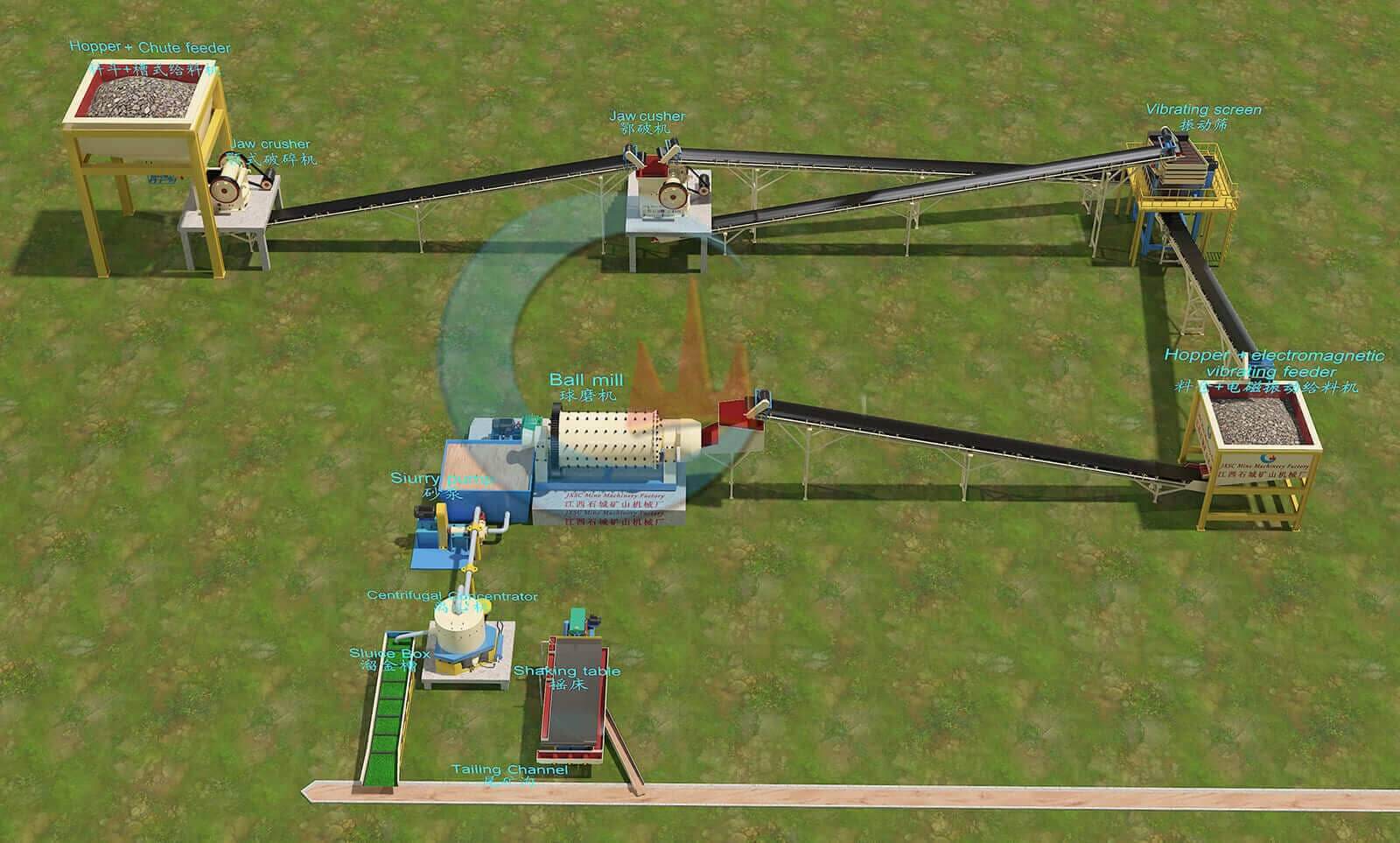

A rock gold gravity processing and recovery plant is designed to extract and recover gold from gold-bearing ores using gravity separation methods. Gravity separation is a widely used method for processing gold ore, especially when the gold is relatively coarse and not finely disseminated within the ore matrix. This approach is often employed for alluvial gold deposits or hard rock deposits where the gold is physically separated from the surrounding rock and minerals based on differences in density.

Rock Gold Gravity Processing & Recovery Plant Steps

Here are the key components and processes typically involved in a rock gold gravity processing and recovery plant:

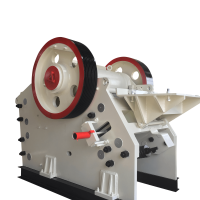

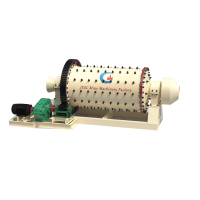

Ore Crushing and Grinding

The process usually begins with crushing and grinding the gold-bearing rocks into smaller particles. This is done to liberate the gold particles and make them accessible for further processing.

Gravity Separation Equipment

Various types of gravity separation equipment can be used in a gold processing plant, including:

- Shaking Tables: Shaking tables are inclined tables with riffles that vibrate in a back-and-forth motion. This action allows denser gold particles to settle on the riffles while lighter gangue minerals are washed away.

- Centrifugal Concentrators: These devices use centrifugal force to separate gold particles from the surrounding material. The high-speed rotation of the concentrator creates a high-gravity field that concentrates the heavy gold particles.

- Jig Separators: Jigs use pulsating water flow to stratify the ore based on density. Heavier gold particles settle into the jig bed, while lighter material is carried away.

Classification and Screening

Prior to gravity separation, the crushed ore may be classified or screened to remove larger particles and ensure proper sizing for downstream processes.

Gold Recovery

Once the gravity separation process is complete, the concentrate containing the gold is collected and further processed to recover the gold. This may involve additional concentration steps or other techniques, such as smelting or chemical leaching, depending on the specific characteristics of the ore and the desired gold recovery rate.

Tailings Management

The tailings, which consist of the discarded material after gravity separation, must be properly managed to minimize environmental impact. Tailings are often stored in tailings ponds or subjected to additional processing to extract any remaining gold.

Water Management

Adequate water management is essential in any mineral processing plant. Water is used for ore transportation, classification, and gravity separation. Effective water recycling and treatment systems are often implemented to minimize water usage and environmental impact.

Environmental Compliance

Compliance with environmental regulations and best practices is critical in gold processing plants to minimize the environmental impact and ensure sustainability.

The specific design and equipment used in a rock gold gravity processing and recovery plant can vary widely depending on the ore’s characteristics, deposit size, location, and economic considerations. Conducting thorough geological and metallurgical assessments is important to determine the most suitable processing methods and equipment for a gold ore deposit. Additionally, safety and environmental considerations are paramount in the design and operation of such facilities.