Sulfide gold tailings beneficiation refers to the beneficiation process of tailings containing sulfide metals to increase metal recovery and reduce environmental pollution. The mineral processing process involves physical and chemical treatment of raw materials to separate valuable minerals.

Sulfide Gold Tailings Beneficiation Processing Steps

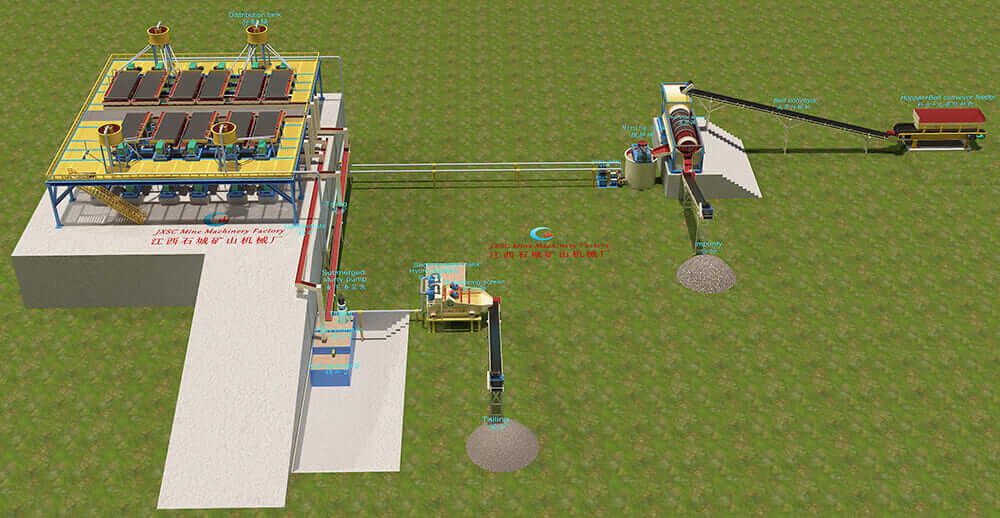

Ore Crushing and Grinding

Preliminary processing involves crushing the gold sulfide tailings into appropriate particle sizes, usually through equipment such as jaw crushers and cone crushers, and then grinding to refine the particles.

Flotation

Flotation is a commonly used beneficiation method for gold sulfide tailings. In the flotation process, crushed and ground tailings and bubble chemicals are placed in a stirred tank. The bubbles adhere to the surface of the gold mineral, causing it to float to the tank’s surface while other ores sink. This enables the separation of gold-containing minerals.

Cyanide Leaching

Cyanide leaching can be used for some gold sulfide tailings containing trace amounts of gold. This is done by adding cyanide to the tailings to form a gold cyanide complex with gold and then extracting the gold through adsorption, precipitation, and other steps.

Gravity Separation

Use gravity separation equipment, such as centrifuges, vibration tables, etc., to further separate the tailings and improve the metal recovery rate.

Tailings Treatment

Treat sorted tailings to reduce adverse impacts on the environment. This may include wastewater treatment, tailings stockpile management, etc.

Process Control and Detection

Real-time monitoring and control of the mineral processing process to ensure the stability of process operations and maximize metal recovery.

Note that the beneficiation process of gold sulfide tailings may be affected by factors such as the diversity of ore components, the particle size of the tailings, and the gold content. Therefore, we must tailor the beneficiation process selection and optimization to the specific tailings properties. At the same time, when beneficiating gold sulfide tailings, follow relevant environmental regulations and safety standards to ensure a safe and environmentally friendly production process.