This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant > Limestone Aggregate Crushing

Limestone Processing Plant

Material: Limestone

Application: It is an important industrial raw material in metallurgy, building materials, chemical industry, light industry, construction, agriculture, and other special industrial sectors.

Equipment: Jaw crusher, impact crusher, sand maker, vibrating feeder, vibrating screen, etc.

Limestone Introduction

Limestone is a sedimentary rock composed mostly of the mineral calcite and comprising about 15% of the Earth’s sedimentary crust. Limestone is the main source of the material lime. It is a basic building block of the construction industry (dimension stone) and a chief material from which aggregate, cement, lime, and building stone are made.

Limestones Types

- Bituminous limestone

- Carboniferous Limestone

- Coquina – A sedimentary rock that is composed mostly of fragments of shells

- Coral rag

- Chalk – A soft, white, porous sedimentary rock made of calcium carbonate

- Fossiliferous limestone

- Lithographic limestone

- Oolite – Sedimentary rock formed from ooids

- Rag-stone – Work done with stones that are quarried in thin pieces

- Shelly limestone

- Travertine – A form of limestone deposited by mineral springs

- Tufa – Porous limestone rock formed when carbonate minerals precipitate out of ambient temperature water

Limestones’s Colors

Pure limestone is gray, off-white, and light colors, while limestone containing much organic matter is gray-black.

Formation of Limestone

Calcium carbonate deposited in lakes and seas is compacted and cemented after losing water, called limestone. The mineral composition of limestone is mainly calcite (accounting for more than 50%) and some impurities such as clay and silt. The formation of the vast majority of limestone is related to biological action. The limestone formed by the accumulation of biological remains includes coral limestone, shell limestone, algae limestone, etc., collectively called biological limestone. Limestone formed by the chemical precipitation of calcium carbonate (CaCO3) in an aqueous solution is called chemical limestone, such as ordinary, siliceous, etc.

Limestone Composition

The main component of limestone is calcite, accompanied by dolomite, magnesite, and other carbonate minerals, and some other impurities are also mixed. Magnesium appears in the form of limestone and magnesite. Silicon oxide is free quartz. Chalcedony & opal are distributed in rocks. Aluminum oxide is combined with silicon oxide to form aluminum silicate (clay, feldspar, mica). Iron compounds are in the form of carbon salt (magnesite), pyrite (pyrite), free oxides (magnetite, hematite), and hydroxides (hydrous goethite). In addition, there is glauconite, and individual types of limestone also contain organic matter such as coal and asphalt, sulfates such as gypsum and anhydrite, compounds of phosphorus and calcium, alkali metal compounds, strontium, barium, manganese, titanium, fluorine, etc. compounds, but at very low levels.

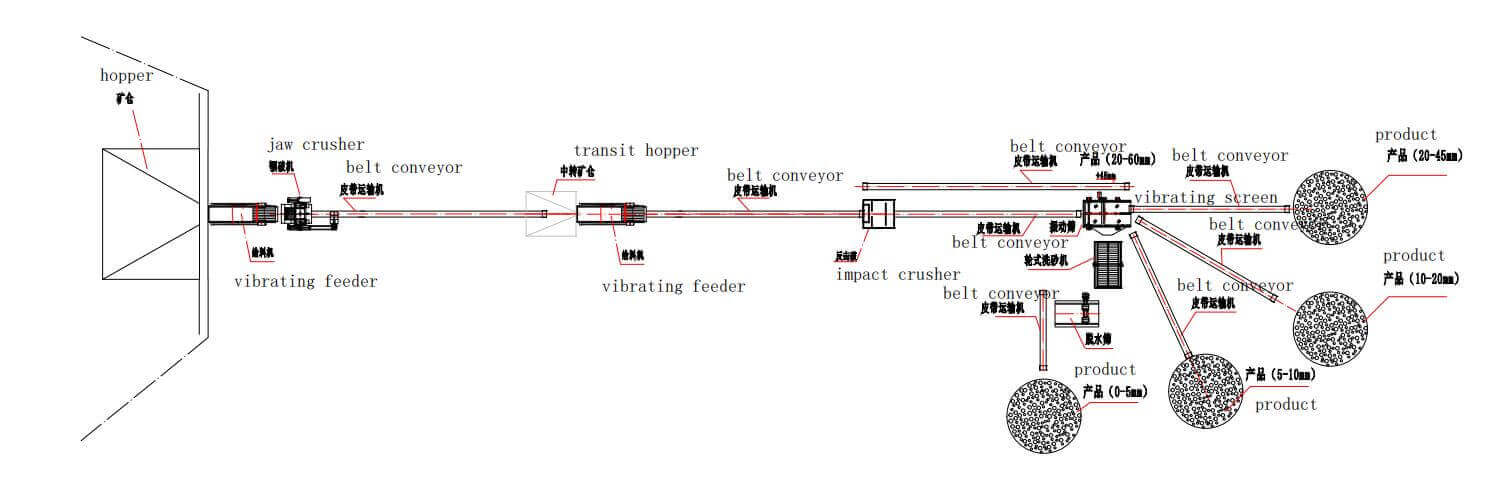

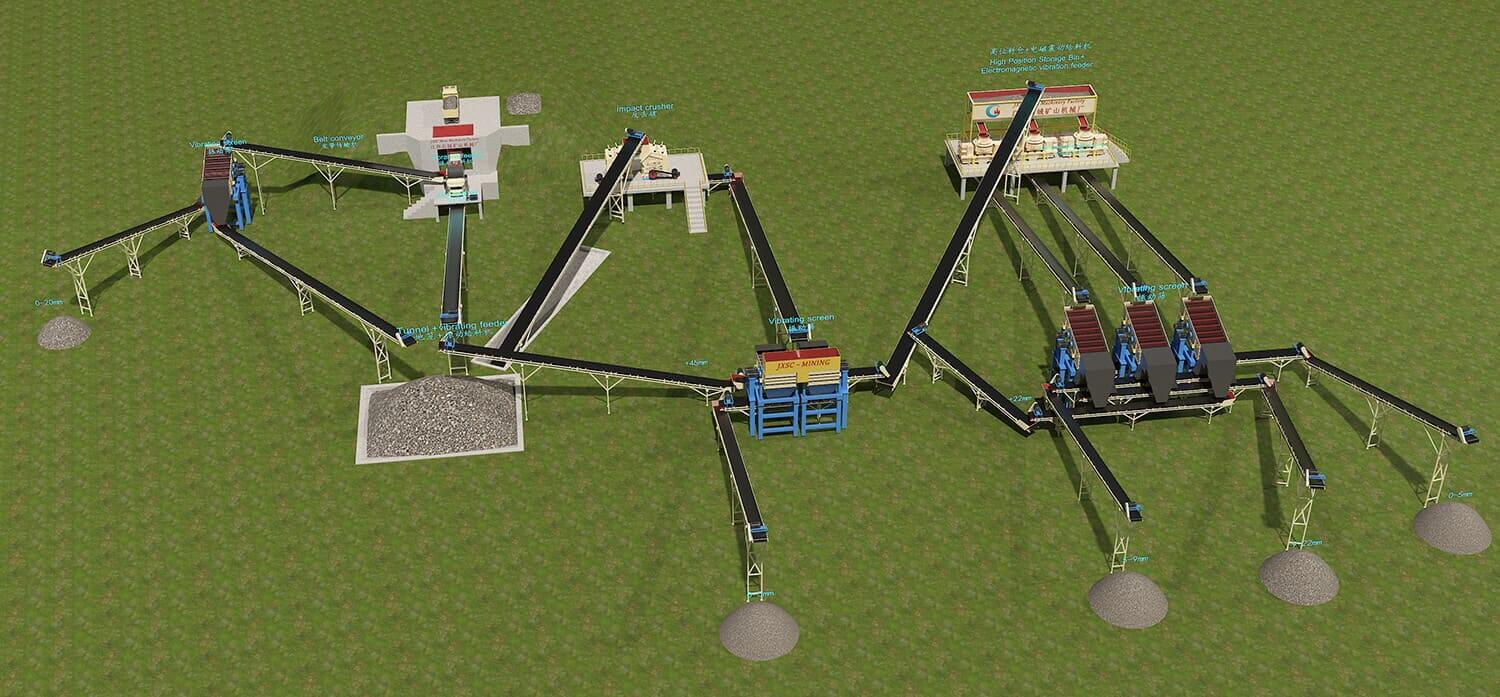

Limestone Crushing & Screening Plant

1. Feeding

The vibrating feeder mainly feeds material into the primary crusher homogeneously and continuously. Meanwhile, it can screen fine materials and improve the crushing ability correspondingly.

2. Coarse Crushing

The jaw crusher is used for the primary and secondary crushing of various materials whose compressive strength does not exceed 320MPa. It has the advantages of a large crushing ratio, high productivity, uniform product particle size, simple structure, reliable operation, easy maintenance, and low maintenance. The crusher is used in mining, metallurgy, construction, automobile, railway, water, and other industries.

3. Medium(Secondary) Crushing

The impact crusher adopts advanced technology and a unique structural design, and the finished product presents a cube shape without tension and cracks, making the particle shape more perfect. It can crush coarse, medium, and fine materials below 500mm and compressive strength below 350MPA, such as granite, limestone, concrete, etc. Impact crusher is widely used in various ore crushing, railway, highway, energy, cement, chemical, construction, and other industries. The output size is adjustable.

4. Screening

The motion trail of this screen is similar to a circle, so it is called a circular vibrating screen. It is a new high-efficiency multi-layer vibrating screen, adopting cylinder-type eccentric shaft vibration exciter and eccentric block to adjust the amplitude. It has a long screening line and can screen out multi-size products. So it is widely applied to mining, building materials, transportation, energy, and chemical industry.

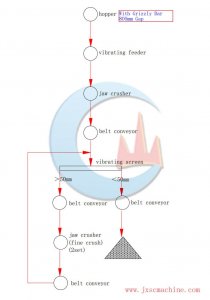

Limestone Sand Making Plant

1. First-stage Crushing

The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing.

2. Second-stage Crushing & Screening

After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the unqualified materials return to the cone crusher for further crushing.

3. Sand Making

The finely crushed Limestone enters the sand-making machine for sand-making processing.

4. Screening

The vibrating screen screens out the material and we get the different sizes of products.

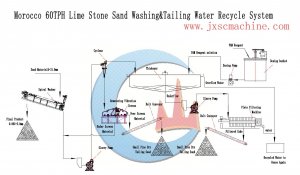

Limestone Processing Solutions

Philippines 200TPH Limestone Crushing Plant

500tph limestone crushing plant flowsheet design in Columbia

500TPH Complete Limestone Crushing Plant