Mineral Processing Cases study: 300TPH Beach Black Sand Processing Plant in Sudan. How processing plant configurated and what equipments were used? Read more…

300TPH Beach Black Sand Processing Plant in Sudan

Published Date:09 September 2020Introduction of beach sand

Raw material: beach black sand, contains no clay

Capacity: 300TPH

Size: 2mm

Grade: Magnetite 6.89%, ilmenite 21.72%, zircon 1.49%, rutile 0.34%, garnet 1.5%, monazite 0.1%, keratite 50%, and other minerals of no recovery value

Customer’s request As much as possible recover the zircon sand, rutile, ilmenite, garnet, etc.

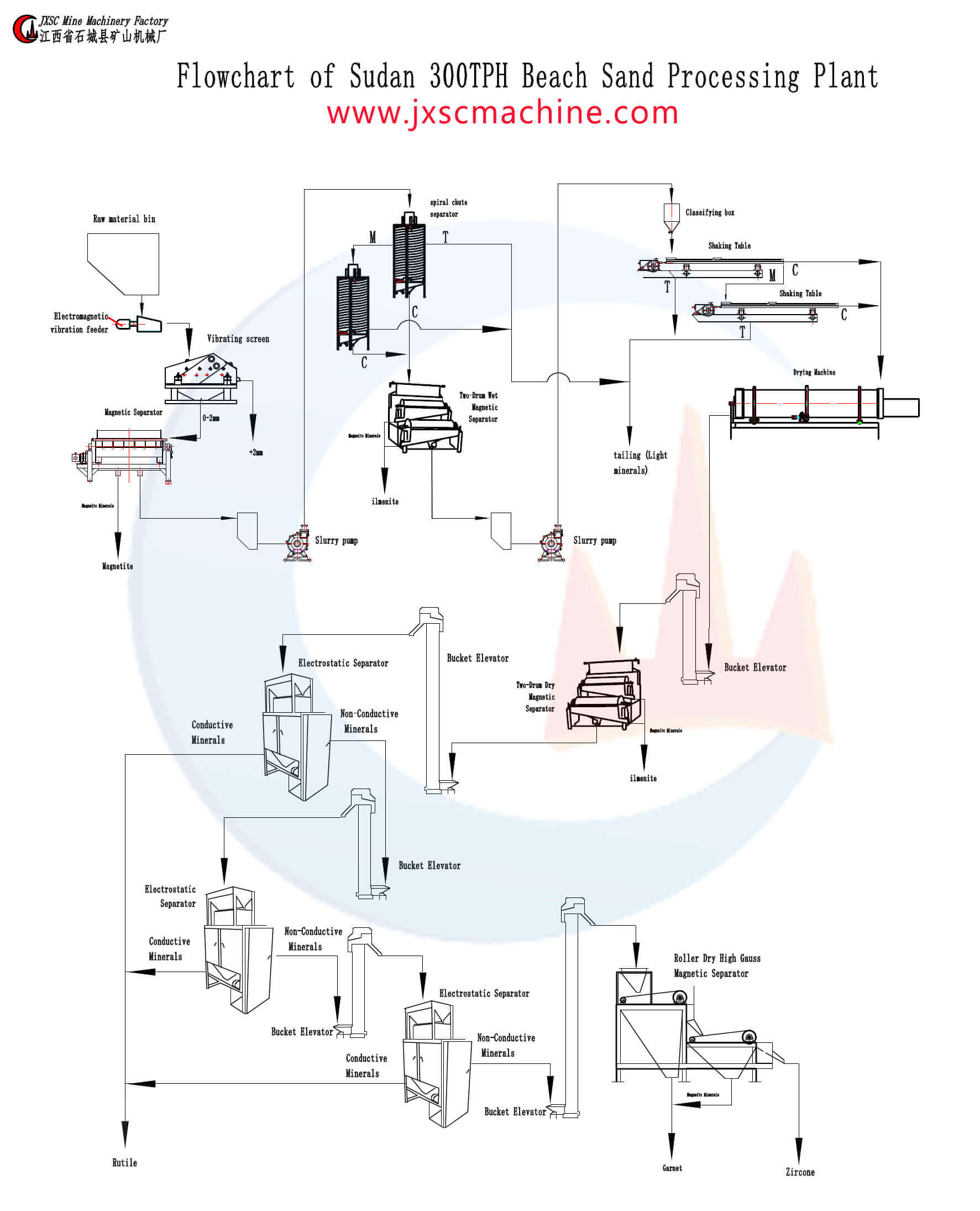

Beach sand processing flow chart

Equipment

| Equipment name | Model | Power(kw) | Qty |

| Vibrating Grizzly Feeder | GZ7 | / | 1 |

| Vibrating screen | 2045 | 11 | 2 |

| Magnetic separator | 1050*2400 | 7.5 | 2 |

| Slurry pump | 8/6 | 55 | 1 |

| spiral classifier | φ1200 | / | 110 |

| Three roller magnetic separator | φ380*1500 | / | 2 |

| Slurry pump | 6/4 | 2.2 | 2 |

| Shaker table | 6s | 1.1 | 40 |

| Dryer | 1200*18m | 37 | 76 |

| Bucket lifter | 7m | 2.2kw | 1 |

| Three roller magnetic separator | 380*1200 | / | 1 |

| Four roller electric separator | 180*1500 | / | 2 |

| Arc plate electric separator | 2A4-30 | / | 1 |

| Strong magnetic separator | 240*1500 | 11000-13000Gs | 1 |

Notes: in order to reduce the investment in the early stage of equipment, belt conveyors and hopper are made locally according to the site conditions.

After-sales service

Before sale

Be a good customer’s adviser and assistant, let the user’s every investment get rich returns.

(1) selection of equipment model.

(2) design and manufacture products according to customers’ special requirements.

(3) training technical personnel for customers.

Sale

Respect customers; Give customers rest assured, a relaxed, a surprise; Committed to improving the overall value of customers.

(1) product acceptance.

(2) assist the client to draw up the construction plan.

After-sale

(1) assign special after-sales service personnel to guide the installation and debugging of customers on-site.

(2) equipment installation and debugging.

(3) on-site training of operators.

Notes:

1. Services (installation, test run, training) : the supplier can provide basic drawings and schematic drawings of equipment installation. The

domestic technicians will be provided for free to guide installation and debugging, and the buyer will provide technicians with room and board.

The buyer shall prepare necessary auxiliary materials for installation.

2. Quality guarantee: the equipment is guaranteed for one year. In the warranty period, due to the quality of the product manufacturing,

manufacturers free warranty (except wearing parts).

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.