Mineral Processing Cases study: 30TPH Zinc and Lead Process Plant in Morocco. How processing plant configurated and what equipments were used? Read more…

30TPH Zinc and Lead Process Plant in Morocco

Published Date:15 November 2021Introduction of Zinc and Lead Process Plant

Raw Material: Zinc and Lead Ore

Capacity: 30TPH

Country: Morocco

Feed size: <400mm

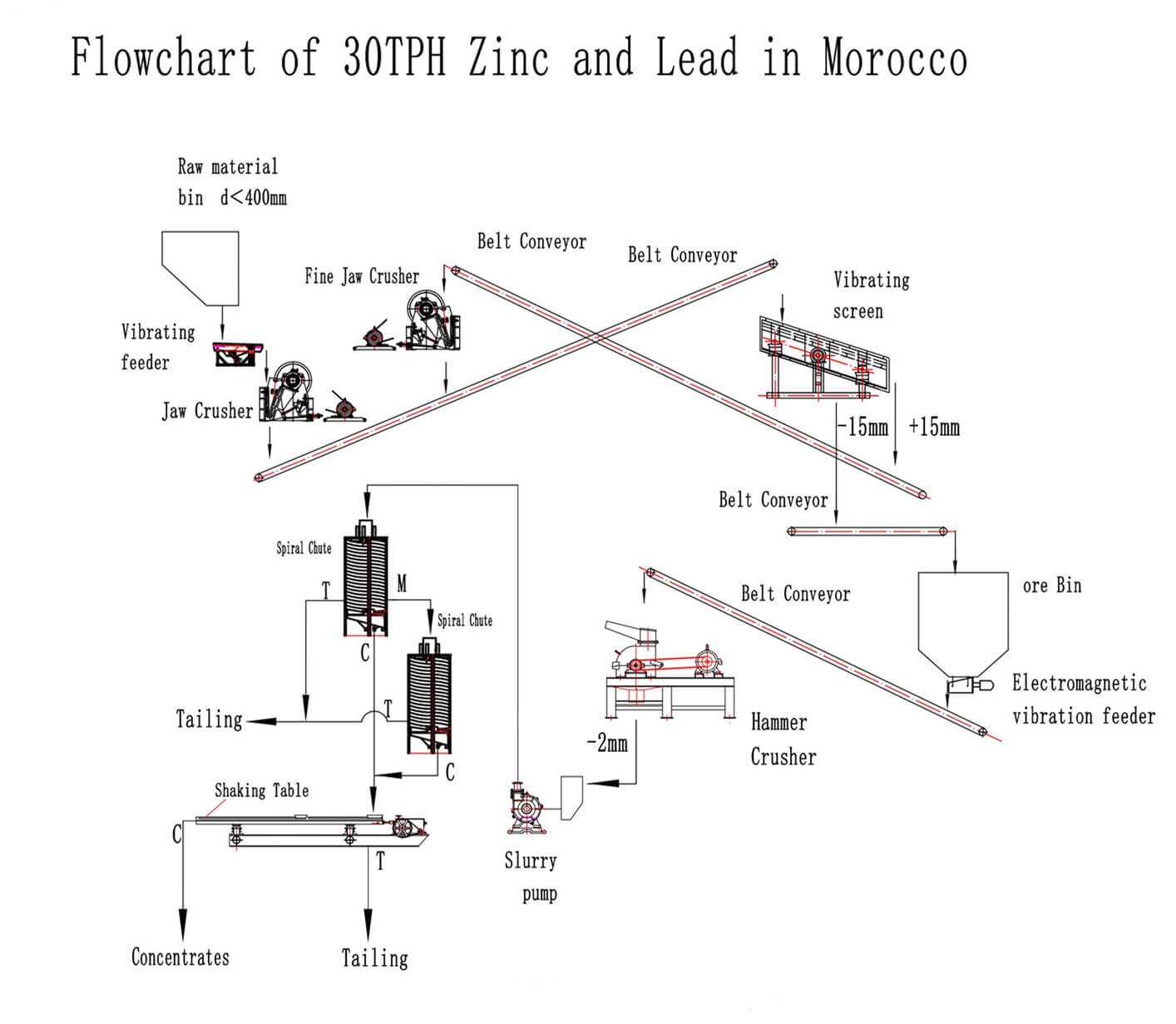

30TPH Zinc and Lead Process Plant Flowchart

Equipment Used in Zinc and Lead Process Plant

- Hopper

- Electromagnetic Vibrating Feeder

- Jaw Crusher

- Belt Conveyor

- Vibrating Screen

- Hammer Crusher

- Spiral Chute

- Shaking Table

- Slurry Pump

Flowchart Description

Customer and Ore Condition

The customer who is from Morocco, lead zinc ore information is below.

1. He already has an old process line, now he wants to replace some machines.

2. The max feeding size is 400mm. 50% size is 100mm,25% size is 150mm & 25% size is 400mm.

3. The capacity is 30tph.

4. Zinc grade: 6-8%, lead grade: 11-13%.

Grinding to 0-2mm can have a good recovery rate of zinc and lead. According to his mining information, our engineers made a flowchart suitable for him.

The Flowchart Steps

1. Use a vibrating feeder to feed the materials to a rought jaw crusher.0-15mm using a belt delivery to vibration screen, over 15mm size to the fine jaw crusher.

2. Send the material after the fine crusher to the vibration screen. Over 15mm size material use a blet return to the fine crusher to grinding it.

0-15mm size materials in a hopper.

3. Use an electromagnetic vibration feeder to feed the material in the hopper to a hammer crusher.

4. After the hammer crusher crushes the material, 0-2mm materials use a slurry pump to first spiral chute group to recovery zinc and lead.

5. The concentrate of first spiral chute group to second spiral chute group to recovery zinc and lead again.

6. Send the concentrate of the second spiral chute group to the shaking table.

7. After the shaking table, we get separate the concentrates and tailings.

Q & A

Q: Why need use two jaw crushers? Can I just use one jaw crusher?

A: Because your max feeding size is 400mm, it’s better to use two jaw crushers, otherwise the output size is too big for a hammer crusher.

Q: Why need a vibration screen, can’t after fine jaw crusher to hammer crusher?

A: For vibration screen,rought jaw crusher has some output size can get 0-20mm, these materials to vibration screen separator 0-15 to the hopper.

Fine jaw crusher has some output size is more than 15mm, these materials to vibration screen then use belt return to fine jaw crusher to grinding it.

Q: Why need two groups of spiral chutes, can I just use one group?

A: If your budget is limited, using one group is ok, but if your budget is ok, we suggest using two groups of spiral chutes, because it can improve the recovery rate, can get more concentrate of zinc and lead.

Notes:

1. Services (Installation, Test Run, Training): The supplier can provide basic drawings and schematic drawings of equipment installation. The

domestic technicians will be provided for free to guide installation and debugging, and the buyer will provide technicians with room and board.

The buyer shall prepare necessary auxiliary materials for installation.

2. Quality Guarantee: The equipment is guaranteed for one year. In the warranty period, due to the quality of the product manufacturing,

manufacturers free warranty (except wearing parts).

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.