With the advancement of the modern construction process, such as construction projects, bridge pile foundation projects, underground tunnels, etc., these constructions will generate a large amount of construction piling mud. Since any discharge will cause pollution to the environment, filter press equipment is required for treatment before being discharged. So how to install and use a filter press? Following we will introduce how to install, debug, and operate safely of the filter press.

How to Install a Filter Press?

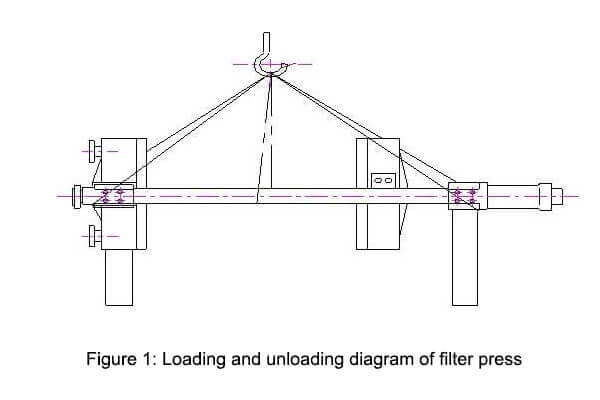

- While loading and unloading, please hoist the structure at the ends of two beams(Shown in Figure 1).

- Filter press should be installed horizontally on a concrete foundation and the SECONDARY grouting is requested. (Note: the support under the end plate should be fixed using screws. The support under the cylinder does NOT be fixed and does NOT be buried by concrete to ensure the beam is flexible during working.) There should be about one meter around the structure for workers’ operations. The Filter press installation should be far away from corrosion, rain, and sun.

- Ensure the 3-phase power is right installed. The motor on the hydraulic station should run CLOCKWISE.

- Fill 76 # or 46 # hydraulic oil into the tank. Standard: the distance of the oil level should be 40 mm. If it’s the first use, after the piston working back and forth, please fill the oil again. While first closing, please release the pressure meter to discharge air into the cylinder.

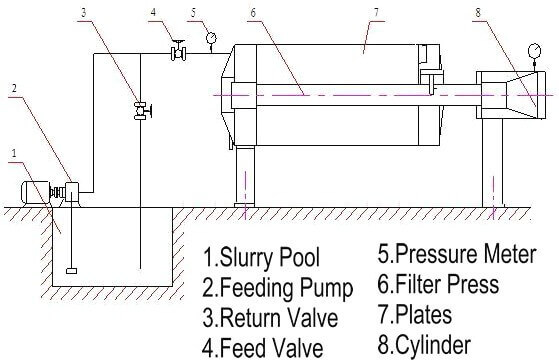

- The feeding pipe should install a backflow pipe, shut-off valve, and pressure meter.

Note: oil pipes of high pressure and low pressure must connect rightly. - Filter clothes should be installed flatly.

- If using a pneumatic diaphragm pump or screw pump as feeding pumps:(1)Pneumatic diaphragm pump: the air pressure should be more than 0.8 Mpa and there must have a relief valve. The pump can be directly connected with the slurry tank and inlet of the filter press. And there should have a pressure meter (0-1.2 MPa) in order to observe the feeding pressure.

(2)Screw pumps or other sludge pumps: return valve and backflow pipe are also necessary and there also should have a pressure meter (0-1.2 MPa). - After installation, please check the filtering system and pipelines whether meet the requirements. After confirmation, the product can be used. (Note: For Manual Jack Filter Press, no need to consider steps 1, 2, 3, and 1, 2, 4.)

How to Debug The Filter Press?

Debugging Preparation

- Please check if the fasteners whether in good condition and if circuits of oil and electricity are rightly installed.

- Please check all driving parts are working smoothly, and the oil pipelines of high pressure and low pressure are installed correctly.

- Please confirm the clothes are installed flatly.

Safe Procedures For Debugging

- If the operator does not know the machine’s performance and operation rules, must not operate the machine without authorization.

- If leakage or abnormal situations (unreliable operation, large noise, vibration, etc.) happen, please turn off the machine immediately and solve the problems.

- While working, examination and repair are not allowed.

- The machine should not work under high feeding pressure.

- Please do not adjust the relief valve casually.

Safeties During Use

- A specified number of plates must be placed in order and It’s forbidden operation to use fewer plates.

- The pressure of the cylinder should not be over the rated value, otherwise, it will damage the relevant parts of the filter press.

- Valves of filtered liquid, washing liquid and compressed air must operate according to the procedures and do not turn on at the same time.

- The slurry temperature must be controlled under 80℃, if it’s beyond 80℃, please inform us in advance.

- While moving the plates, the force should be even and appropriate to avoid damage to plates and handles.

- After filtration, plates and cloths must wash clean. There should be no residues on the surface, otherwise, it might cause deformation.

- The filter cloth must meet the requirements of slurry, otherwise, the filtrate will be not clear, or the filtering speed will be too slow to get the best filtering effect.

- After a period of working, the filter cloth will be hard and their performance might decrease, so it’s very necessary to conduct a routine inspection. If clothes become hard, please neutralize, immerse and wash them using the corresponding weak acid alkali.

- Hydraulic parts say, oil tank, cylinder, oil pump, relief valve, etc., should perform some no-load running regularly. Normally, for the first use, the oil should be changed in one month. Then every 6 months the oil should be changed one time. The filtering precision should be 20 um.

- The structure should be clean and the screw part should be lubricated with butter. The plate shifter and driving mechanism should keep smooth using lubrication oil. Please do not climb and strike the pipes connecting with the inlet and outlet to avoid leakage at the joints.

Safety Precautions

- Operators must be trained to operate the machine.

Operators must know the basic operation processes and daily maintenance of filter press to avoid harm caused to workers and our product. - Please turn off the power after work and when maintenance.

When malfunction happens, please close the power. - Please do not disassemble the hydraulic system and electrical system without training.

The electricity of the hydraulic system and electrical control system has high voltage, please do not disassemble them without authorization. - Please do not adjust the transducer’s position and meter’s parameter without authorization.

Factory settings are not allowed to be adjusted without authorization. It’s harmful to the filter press. - Please pay much attention to rotatable parts to prevent injuries.

Please do not touch any rotatable parts while working to avoid injuries. - Please wear a related protective device

In some special situations, operators must wear protective devices.

The Pipeline of Filter Press

Operation procedures

- Close and squeeze plates.

- Open valve 4, shutoff valve 3.

- Turn off the feeding pump.

- Observe the pressure during the whole filtration course. According to the on-site situation, please endure the feeding pressure is under rated pressure by adjusting the return valve.

- Finally the filtered liquid will be little, then please close the feeding pump. If the cake does not need washing, please discharge the cake.

- When open plates, if the cake is not dry enough, plates also can be closed and continue to work again.

- If the pneumatic diaphragm pump is the feeding pump, it’s not necessary to install the relief system.

Although there are various filter presses, the installation and debugging of filter press is almost the same, and the safety precautions during operation are general. If you are willing to know the maintenance, please click here to read.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…