In the process of using the filter press, we will inevitably encounter some problems. Now we will summarize the common filter press problems from the following aspects: filtration, maintenance, troubleshooting, etc., And introduce various schematic diagrams including cloth installation, pipeline, wiring scheme, and electrical schematic diagram.

Filtration

1. What are the factors that affect the filtering effect?

The filtration effect will be various according to the slurry’s condition, such as solid content, temperature, ph value, particle size, etc. Or even some slurries need to add chemical powders to regulate the slurry’s filtering performance, such as filtration aid, flocculant, etc. And the final cake will be different.

2. Is it normal that the filtered liquid is not very clean at the beginning of filtration?

At beginning of filtering, the filtered liquid will be not very clean, because the precoat is not formed. Please continue to work and it will be better after a while.

3. Is little leakage reasonable?

Little leakage is reasonable, because of cloth capillarity/wicking. If big leakage happens, please increase some closing pressure (a little).

4. How to deal with the sudden turbidity of filtrate?

Please observe the filtered liquid, if suddenly filtrate is muddy, please close the tap. (For close filtrate filter press, please stop the machine.) Then check the clothes.

5. When is the filtering finished?

If the pressure is higher and the liquid flow is very small, the filtration is finished.

6. What should I do if the filtration time is too long or the cake cannot be made?

If the filtering time is too long or the cakes can not be formed, please try to lower the liquid content, such as increasing precipitation time; using thickener; adding filtration aid and flocculant, etc.

7. How to clean the cake?

If cakes need washing, please close the taps on the washing plates and feeding valve, then fill in the water to wash the cakes. The water pressure should not be over the rated pressure. The washing time is decided by the filtering effect.

8. How to do to achieve a better dehydration effect?

To realize a better dewatering effect, the cakes can be blown by compressed air and the method is the same as the above. The compressed air also can be fed in via a feeding hole. Or use membrane filter press directly.

How to Maintain The Filter Press?

- Operators must know the operation instructions and strictly operate the machine according to the manual.

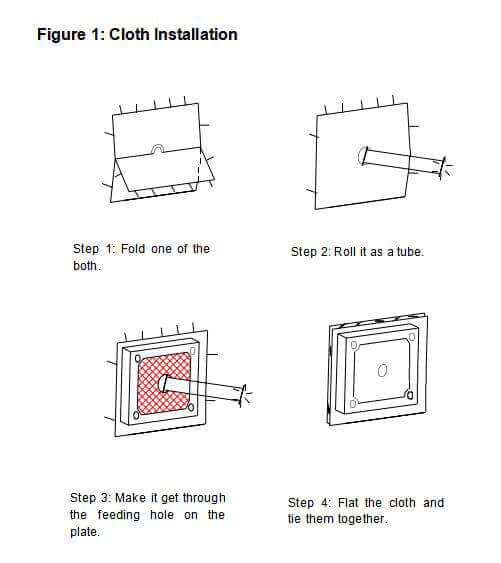

- Please use good filter clothes and the clothes must be flat.

- Please often check every part of the product whether in reliable condition: the fastener is fixed; the hydraulic system has no leakage; every driving part works smoothly etc.

- Regularly check the hydraulic oil’s quality. The hydraulic system must keep clean. The oil temperature should be no more than 60 ℃. Often check the oil filter. When it’s winter, please ensure the temperature is more than 15℃.

- After changing the oil pipe, then use the machine the first time, please keep off the high-pressure oil pipe.

- Every use, please check the working situation. If there is abnormal, please turn the machine off and repair it.

- A monthly Insulation test for electric parts is necessary.

- The feeding pressure, closing pressure and the slurry temperature must be strictly under the rated value. And if the following situation happens, the filter press must not be turned on: the number of plates is not enough; the max distance of the closing plate is smaller than the cylinder distance.

- As for the mechanical filter press, please pay much attention to the closing conditions. Please do not run with overload for a long time.

- After discharging, please wash the clothes and plates.

- If long time does not use the machine, please store it in a dry and ventilative place. The relative moisture should be no more than 80% and the temperature should be around 0-40 ℃. The hydraulic system should be filled with oil. The surface of the naked structure should paint with anti-rust oil.

- Plates and frames should keep off materials that may cause damage, and please keep away from heat, rain, sun, etc.

- When using a membrane filter press, before air squeezing, the chamber must be filled with slurry. And before opening the plates, the compressed air must be discharged in advance. Otherwise, plates might be broken. While filtering, please pay much attention to air pipes, if abnormal happens, please close the air feeding valve and discharge the air. After repair, it can be used again.

Troubleshooting & Solutions of Filter Press

| Faults | Possible Reasons | Solving Methods | ||

| The hydraulic system has serious noise or pressure is not stable | There is no oil in the tank or the oil pipe is blocked | Add oil, clean the pipes oil | ||

| Plate sealing surface has impurities | Clean it | |||

| There has air in the oil pipes | Discharge the air | |||

| The pump is damaged | Replace or repair | |||

| Relief valve can not work stably | Replace or repair | |||

| Oil pipe shakes | Fix them | |||

| The closing pressure is not enough or even no pressure | The oil pump is damaged | Replace or repair | ||

| The pressure adjustment is wrong | Adjust it again | |||

| Oil viscosity is low | Change the oil | |||

| Oil leakage | Repair | |||

| While squeezing plates, the pressure is not enough | The high-pressure relief valve is blocked or damaged | Replace or repair | ||

| Reversing valve is damaged | Replace or repair | |||

| The seal of the big piston is broken | Replace | |||

| “O” seal of the small piston is damaged | Replace | |||

| The oil pump is damaged. | Replace or repair | |||

| The pressure is not adjusted rightly | Regulate it again | |||

| While the cylinder is coming back, the pressure is not enough | The low-pressure relief is blocked or damaged | Replace or repair | ||

| The seal of the small piston is damaged | Replace | |||

| The “O” seal of the small piston is damaged | Replace | |||

| The piston crawls | The oil circuit has air | Replace or repair | ||

| The transmission box has a serious noise | Bearing is damaged | Replace | ||

| Gears are damaged | Replace or repair | |||

| Serious leakage between plates | Deformation of plates and frames | Replace | ||

| There are impurities on the sealing surface | Clean | |||

| Clothes are not flat | Replace or flat them | |||

| Closing pressure is not enough | Increase the closing pressure | |||

| Deformation of plates or frames | The filtering pressure is too high | Decrease the pressure | ||

| The temperature of the slurry is too high | Decrease the temperature | |||

| The closing pressure is too high | Adjust the closing pressure | |||

| The filtering speed is too fast | Slow down the filtering speed | |||

| The inlet is blocked | Clean the inlet | |||

| The machine stops during working | Do not stop during working | |||

| Often pressure complement | One-way valve is not good closed | Replace | ||

| Cylinder has leakage | Replace the seal | |||

| The direction valve can not work | The valve plug is blocked or damaged | Clean or replace it | ||

| Plate shifter can not be pulled back | The pressure of the oil motor is low | Regulate it | ||

| The pressure of the pressure relay is low | Regulate it | |||

| Membrane is damaged | Air pressure is not enough | Lower the air feeding pressure | ||

| The feeding slurry is not enough | Filled chamber with slurry | |||

| The membrane might be punctured by impurities | Remove the impurities | |||

| Beams bend | The foundation is not firm and flat | Repair or rebuilt | ||

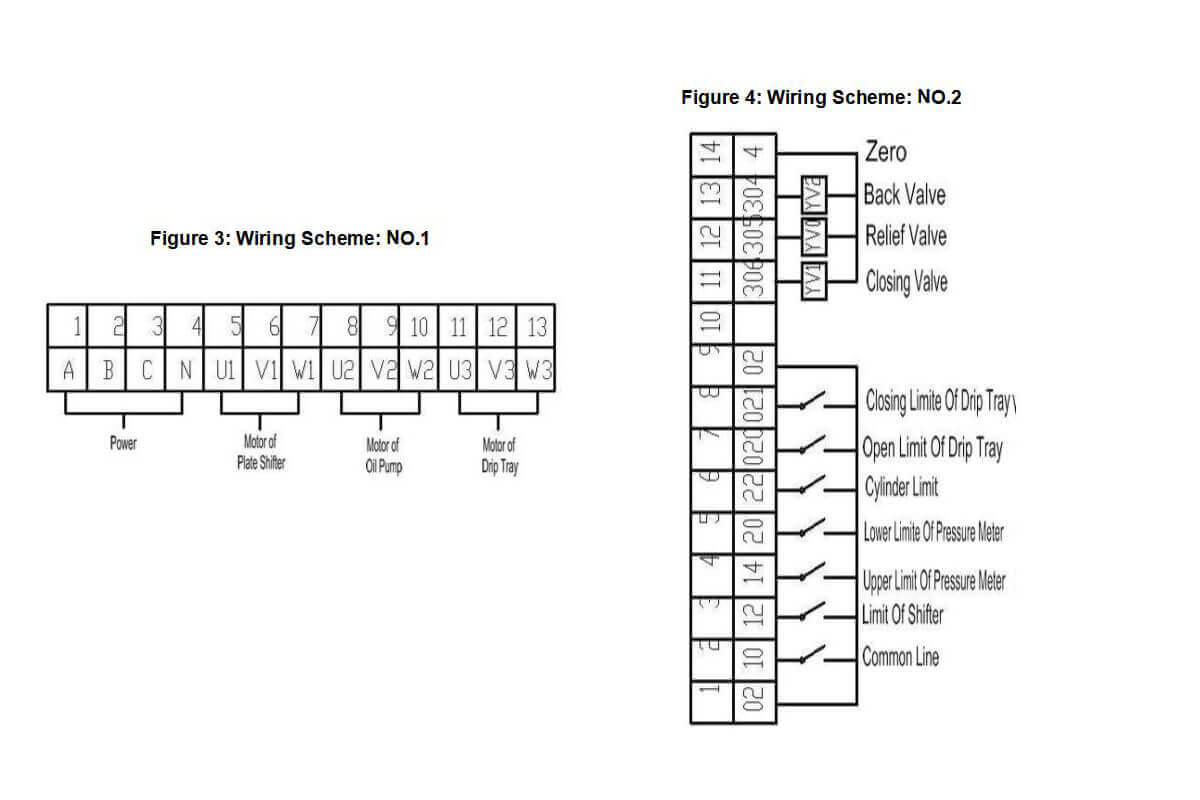

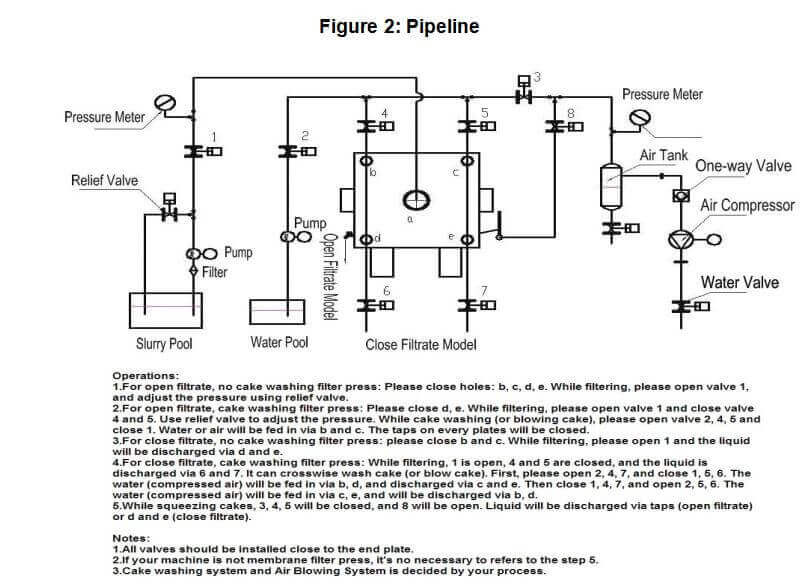

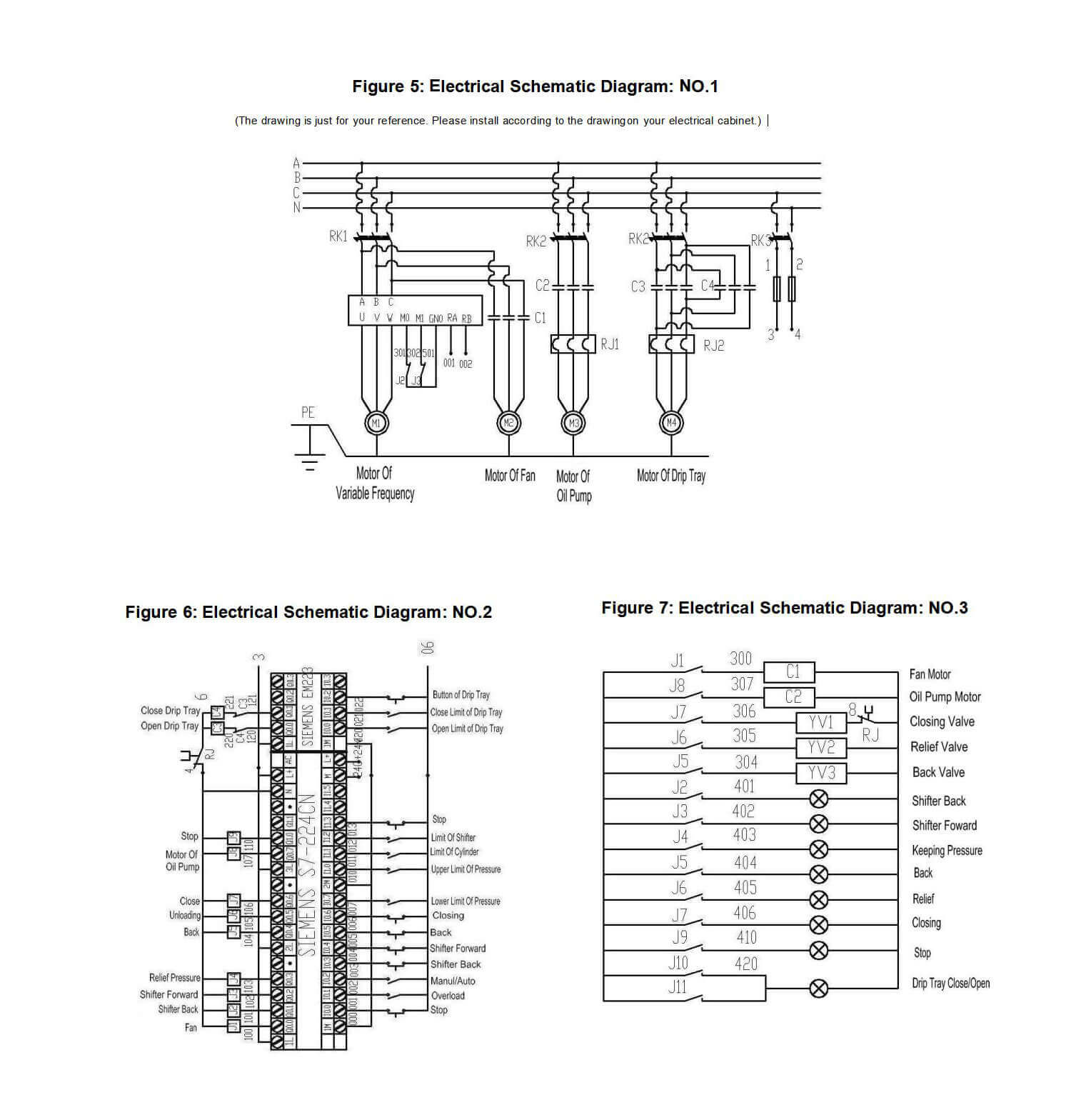

Filter Press Schematic Diagrams

Note: The above drawings are just for your reference. Please install according to the drawing on your electrical cabinet.

Extended Reading

How to Install, Debug and Operate Filter Press Safely?

Filter Press Manual

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…