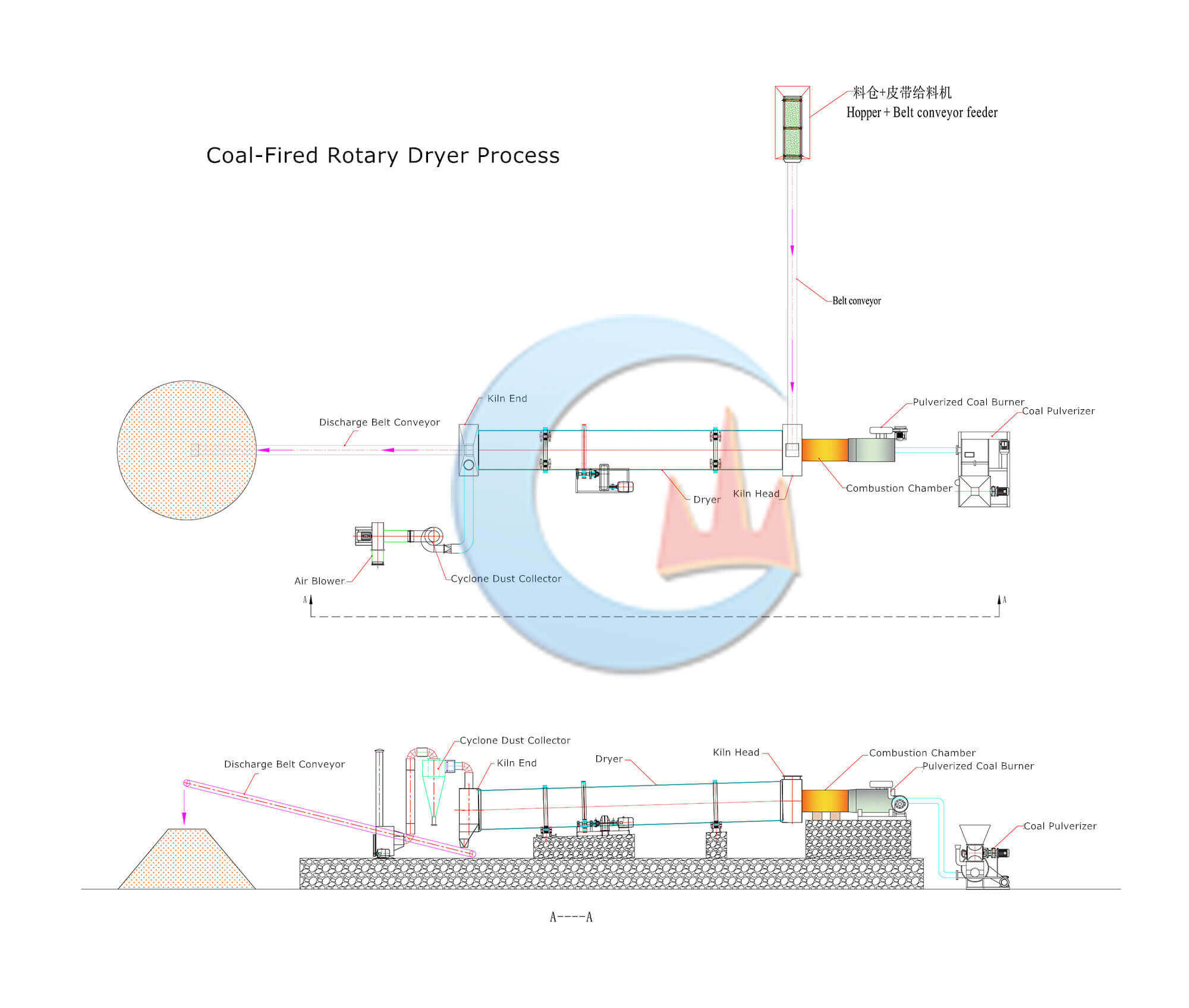

A coal-fired heating rotary dryer is a standard industrial drying equipment mainly used for heat treatment and high-humidity drying materials.

The coal-fired rotary dryer working principle is to evaporate the moisture in the material and dry it through the thermal energy generated by burning coal.

The rotary dryer can dry coal, slag feed, biomass fuel, slag ore, river sand, and other high-humidity materials to promote recycling and comprehensive utilization. It is widely used in various industrial fields, such as the coal industry, metallurgy industry, building materials industry, etc., for drying and heat treatment of materials with high humidity, such as coal, ore, slag, chemical products, etc. It has the advantages of low fuel cost, stable heat output, strong adaptability, etc.

As standard drying equipment, the coal-fired dryer has the following characteristics and advantages:

Low fuel cost: Coal is relatively cheap and widely available as the primary fuel. Compared with other fuels, such as natural gas or electricity, coal has a lower fuel cost, which can effectively reduce production costs.

Stable heat output: Coal combustion produces high heat energy, which can provide stable high-temperature hot air to ensure uniform and stable heat output during the drying process, which is conducive to improving drying efficiency and product quality.

Strong adaptability: coal-fired dryer is suitable for processing various materials, such as coal, ore, slag, chemical products, etc., and has a wide range of applications. It can meet the drying needs of different materials and has good adaptability.

Large processing capacity: Coal-fired dryers usually have a large processing capacity and can handle many materials. Mass production and industrial applications must be able to meet the demands of production lines.

Simple and reliable structure: The structure of the coal-fired dryer is relatively simple, and the operation and maintenance are relatively easy. The combustion and hot air systems are equipped with reasonable control devices, which can achieve stable operation and efficient heat transfer, ensuring the reliability and safety of the equipment.

1. Feeding

The feed chute or belt conveyor feeds the material to the dryer. And use a coal pulverizer to grind the coal and inject the coal into the pulverized coal burner.