Potash feldspar belongs to the feldspar family of minerals. According to its density, hardness, and the components and characteristics contained, it is widely used in glass, electric porcelain and other industrial manufacturing and potassium fertilizer. In addition, potassium feldspar can be ground into ultra-fine white ash powder, which can be used in construction, agriculture, industry, rubber, metallurgy and some high-tech industries.

Potassium

Release time:26 August 2019

Description

Potassium feldspar crusher machine

Potash feldspar has high density, hardness, and silica content, which would cause serious wear on the crusher parts like the plate, hammer, chamber. Therefore, in the design of the potash feldspar crushing process, the crushing machine of the lamination principle is used as much as possible to reduce the wear of the wear-resistant parts. Potash feldspar crushers include jaw crusher, cone crusher, and impact crusher.

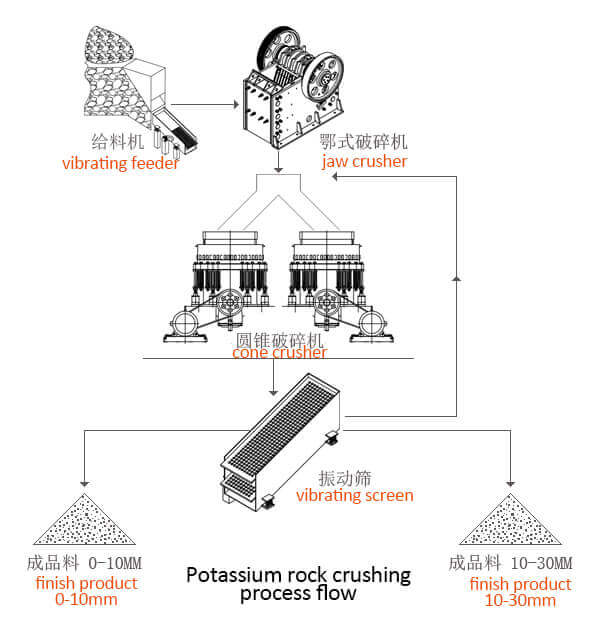

Potassium rock crushing process

The raw materials are fed into the silo via a dump truck, and the materials are evenly fed into the jaw crusher through a vibrating feeder to prevent the material from impacting the crushing cavity to cause damage to the equipment. At the same time, the situation of overloaded stuffy cars is avoided.

The jaw crusher performs initial crushing, crushing the material to a particle size of about 250mm, and then uniformly feeding the crushed material into the cone crusher through a belt conveyor for secondary crushing.

The vibrating screen is used for sieving and grading. Materials larger than 31.5mm are returned to the cone crusher for further crushing. Materials below 31.5mm are divided into 0-10mm and 10-30mm materials by the belt conveyor to the finished product pile.

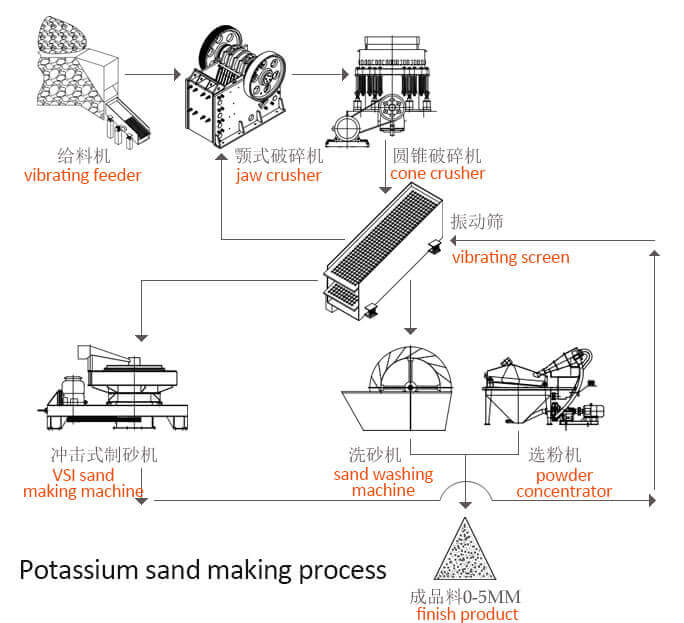

Potassium sand making process

Potassium feldspar raw material is sent into the raw material warehouse by the forklift or dump truck, and then evenly fed into the jaw crusher by the vibrating feeder, crushing the material to the size of about 150mm, and then sent to the cone crusher for the second crushing.

The crushed material is classified by a vibrating screen, and the 0-5mm material is sent to the finished product pile by a belt conveyor.

The material> 30mm is sent by the belt conveyor to the cone crusher and then broken by the vibrating screen to form a closed circuit.

5-30mm material is sent to the high-efficiency centrifugal impact sand making machine through a belt conveyor for crushing. The crushed material is classified by a vibrating screen, and 0-5mm material is sent to the finished product pile by a belt conveyor. The material is again sent to the high-efficiency centrifugal impact sand making machine to be broken, forming a closed circuit, until the material meets the specifications of the finished product, and then sent to the finished product pile.

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.