This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant > Andesite Crushing Plant

Andesite Crushing Processing

Material: Andesite stone

Application: Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

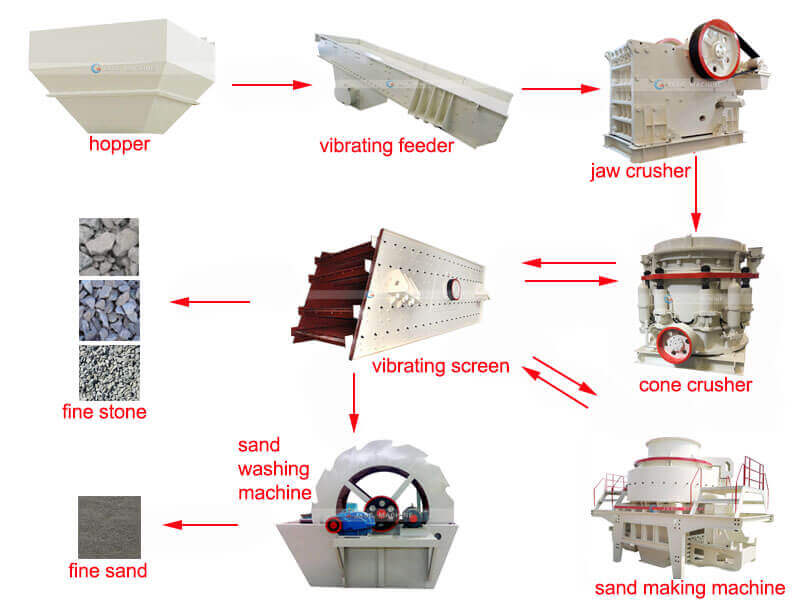

Equipment: Jaw crusher, cone crusher, sand making machine, vibrating feeder, vibrating screen, etc.

Andesite Introduction

Andesite is an igneous rock that is commonly found in volcanic environments. It belongs to the intermediate composition category of stones, which falls between the more silica-rich (felsic) rocks like granite and the more silica-poor (mafic) rocks like basalt.

Andesite’s Name Origin

Andesite gets its name from the Andes Mountains in South America, which are abundant due to its volcanic activity. However, andesite can also be found in other volcanic regions worldwide.

Formation of Andesite

Andesite is formed through the solidification of molten magma or lava. It typically occurs when magma rich in silica and dissolved gases erupts onto the Earth’s surface and cools relatively slowly. This slow cooling allows minerals to crystallize, resulting in a fine-grained rock texture.

Andesite Mineral Composition

The mineral composition of andesite usually includes plagioclase feldspar, pyroxene, and sometimes amphibole. It often has a gray to dark gray color, although variations in mineral content can give it different shades, such as green or reddish hues. Andesite may also contain small amounts of other minerals, such as quartz or biotite.

Due to its composition and characteristics, andesite is valued for its strength, durability, and resistance to weathering. It applies in mining, metallurgy, construction, highway, railroad, water conservancy, etc.

Andesite Stone Crushing(Sand Making) Plant

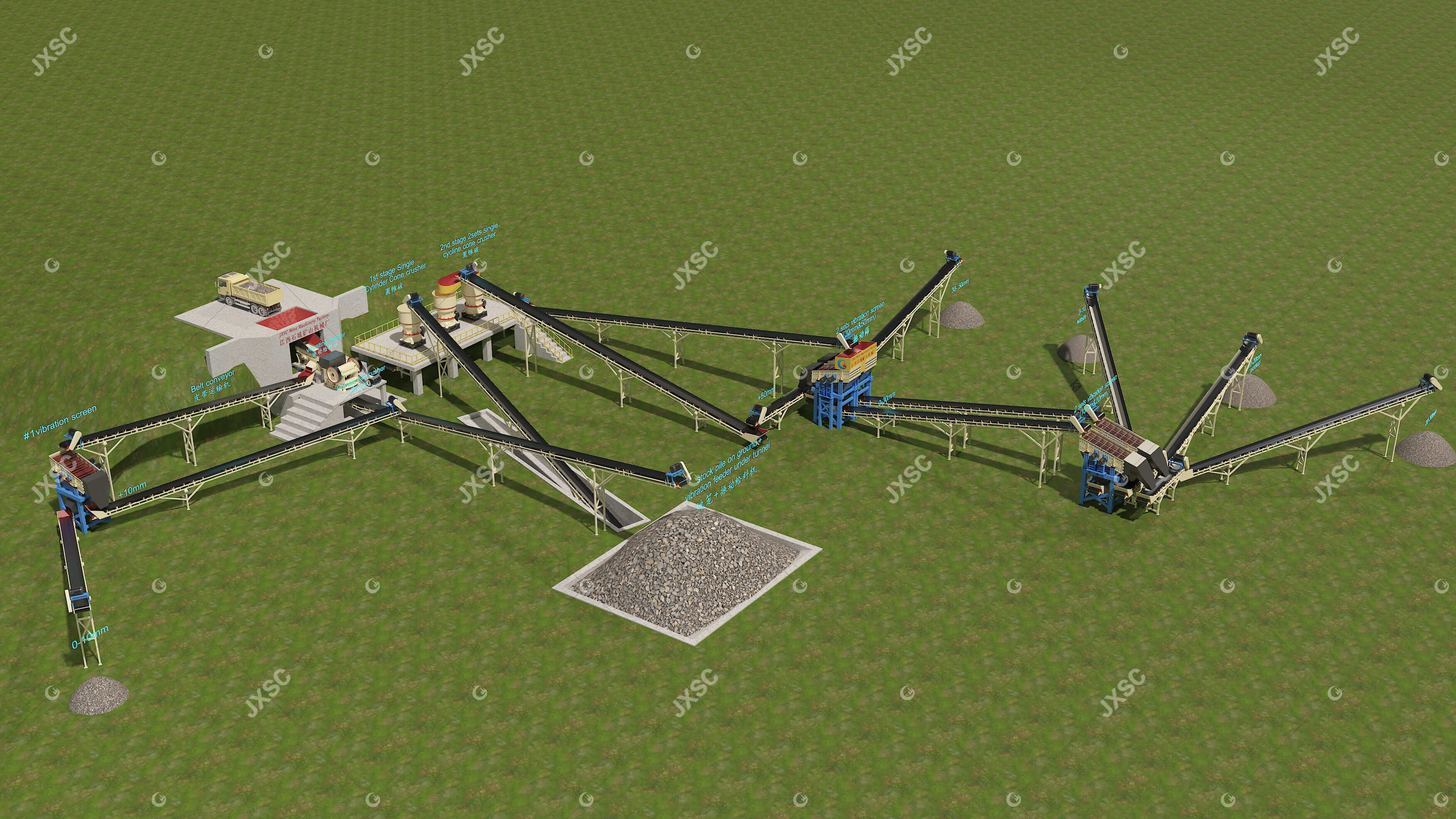

An andesite crushing plant refers to crushing and processing andesite rocks into various sizes for different applications. The crushing plant typically consists of primary, secondary, and tertiary crushers, screens, conveyors, and other equipment necessary for the crushing process.

Main Stages of Andesite Sand-Making Plant

- Primary Crushing

Feed the andesite rocks into a primary crusher(a jaw or gyratory crusher). The primary crusher reduces the size of the stones to a more manageable and uniform size.

- Secondary Crushing

The crushed andesite from the primary crusher is further reduced in size by a secondary crusher. Commonly used secondary crushers include cone crushers and impact crushers. The secondary crushing process helps to produce a finer and more consistent product.

- Tertiary crushing(optional)

Sometimes we need to use a tertiary crusher to refine the crushed andesite into smaller sizes. Tertiary crushers can be cone crushers, impact crushers, or vertical shaft impact crushers (VSI sand makers), depending on the desired end product shape and size.

- Screening

After the crushing stages, screen the andesite materials to separate different sizes or grades, which use vibrating screens that allow the smaller particles to pass through. In contrast, return larger ones to the crushers for further crushing.

- Conveying and Storage

Conveyors transport the crushed and screened andesite from one stage of the crushing process to another. They help in efficient material handling and can store the crushed andesite in stockpiles for future use.

- Washing and Classification (optional)

Sometimes, andesite aggregates may undergo washing and classification processes to remove impurities and obtain a more refined product. Washing and Classification are particularly common in the production of high-quality aggregates for concrete.