This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant > Granite Aggregate Processing

Granite Processing Plant

Material: Granite

Application: Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

Equipment: Jaw crusher, cone crusher, sand-making machine, vibrating feeder, vibrating screen, sand washing machine, etc.

Granite Introduction

Granite is a light-colored plutonic rock found throughout the continental crust, most commonly in mountainous areas. It’s a hard igneous rock with coarse, visible quartz crystal grains.

Granite is high in quartz (about 25%), feldspar, and mica. It is widely used for architectural facades, construction materials, ornamental stones, and monuments. Over 40% of dimension stone quarried is granite. Crushed granite is a durable construction material in asphalt and concrete used in highway and infrastructure projects.

Granites’s Colors

Granites are most easily characterized as light-colored and coarse-grained due to cooling slowly below the surface. Color variation responds to the percent of each mineral found in the sample. The crystals in granite provide a variety of mixed colors — feldspar (pink or red), mica (dark brown or black), quartz (clear pink, white, or black), and amphibole (black).

Formation of Granite

Granite is the most widespread of igneous rocks, underlying much of the continental crust. Granite is an intrusive igneous rock. Intrusive rocks form from molten material (magma) that flows and solidifies underground, where magma cools slowly. Eventually, the overlying rocks are removed, exposing the granite. Granites usually have a coarse texture (individual minerals are visible without magnification) because the magma cools slowly underground, allowing larger crystal growth.

Granite Composition

The main minerals of granite are feldspar, quartz, black and white mica, etc., and the content of quartz is 10%~50%. The content of feldspar is about 2/3 of the total, and it is divided into orthoclase, plagioclase (soda lime), and microcline (potash). Different varieties have different mineral compositions and may also contain pyroxene and hornblende.

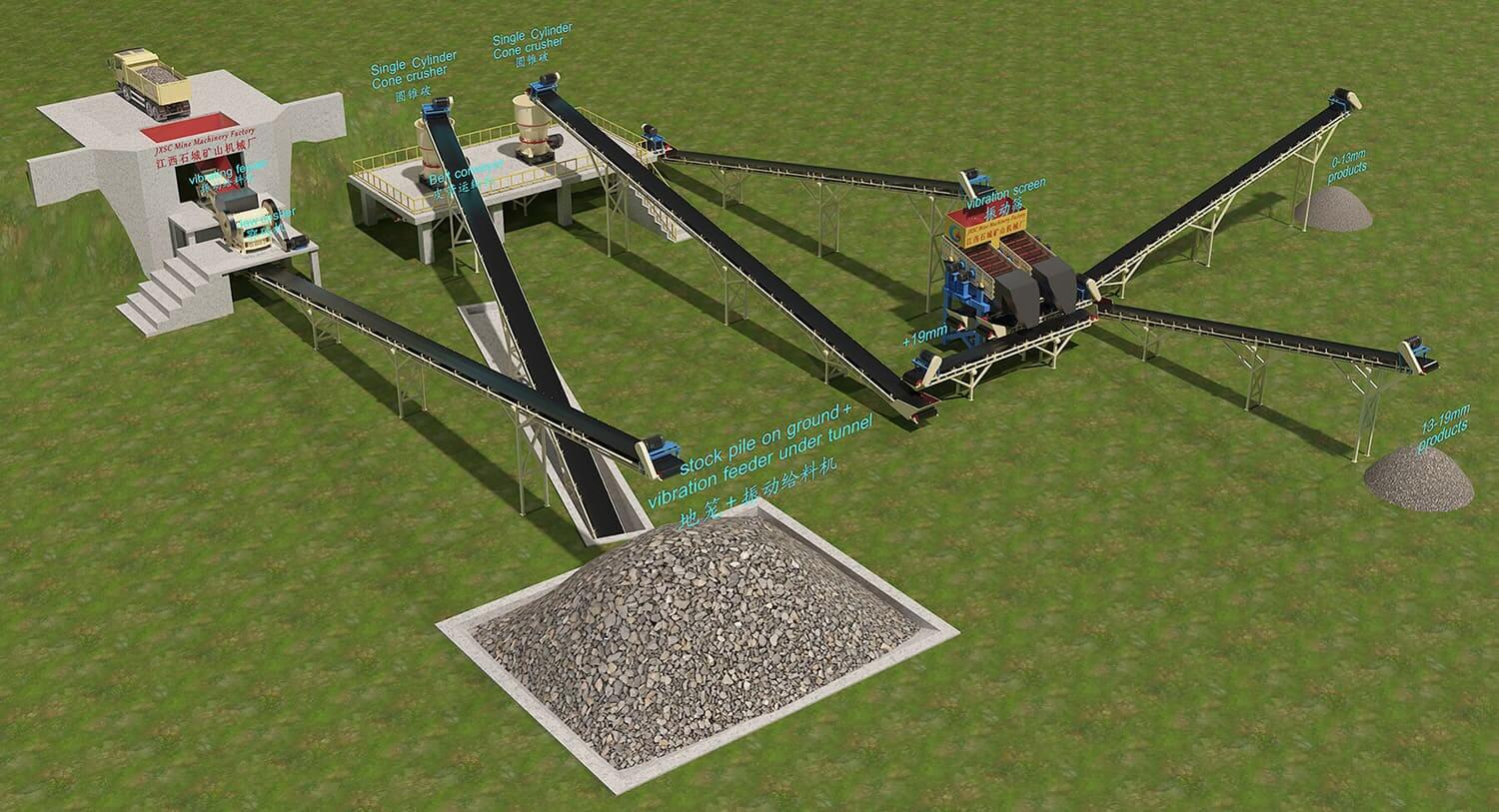

Granite Crushing Process

1. Feeding

Put the granite crushed stone into the jaw crusher with a vibrating feeder, and put it into the jaw crusher evenly to prevent clogging.

2. Coarse Crushing

The jaw crusher roughly crushes the granite for a while, the input particle size can reach below 1200 mm, and the output range is controllable.

3. Medium(Secondary) Crushing

When the granite is crushed below 560mm, use the cone crusher for the secondary crushing, which has high strength and uniform discharge. Most importantly, the wear-resistant parts are made of high manganese steel, which is pressure-resistant, wear-resistant, and high-temperature resistant.

4. Screening

The vibrating screen screens the material into finished products of different specifications through a strong exciting force and is not easy to be blocked.

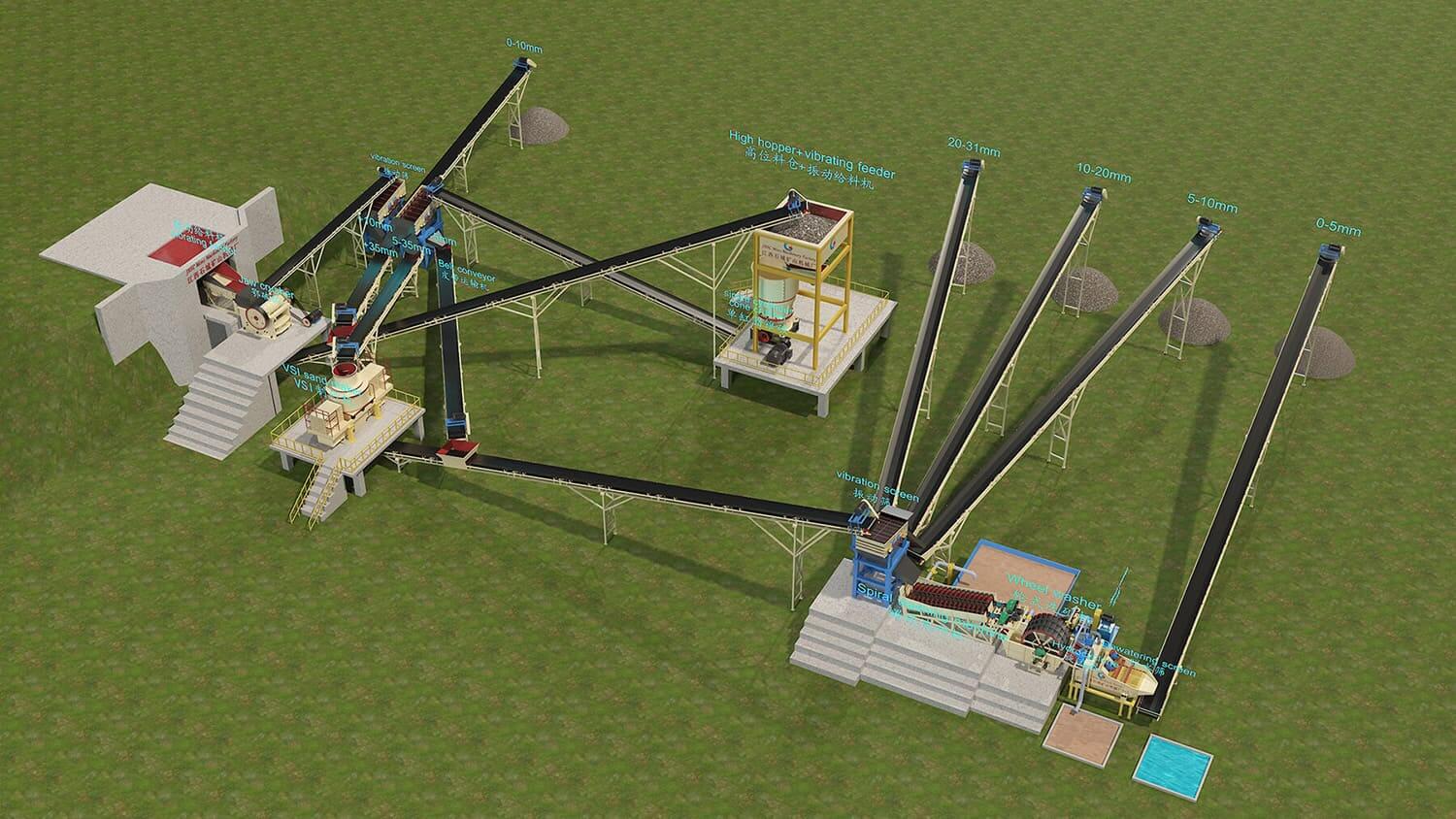

Granite Sand Making & Washing Plant

1. First-stage Crushing

The granite raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing.

2. Second-stage Crushing & Screening

After coarse crushing, the granite gravel enters the cone crusher for fine crushing and then uses a vibrating screen for screening operation. The qualified materials flow into the next process, and the unqualified materials return to the cone crusher for further crushing.

3. Third-stage Crushing(Sand Making & Shaping)

The finely crushed granite pebbles enter the sand-making machine for sand-making processing.

4. Sand Washing

Clean the qualified sand from the sand-making machine by the sand washing machine and then transport it to the finished product warehouse by the conveyor, which is the finished product. The sand washing machine can be added as appropriate according to the actual needs of users.

Advantages of Granite Crushing Plant

- High degree of mechanization

The equipment of the production line is well coordinated, does not need to consume too much labor cost, the machine performance is stable, and the production efficiency is high. It can produce high-quality finished aggregates for most investment users and increase user benefits. - A wider range of use

The granite crushing production line can carry out coarse, medium, and fine crushing of granite, and the finished aggregate produced has a more beautiful grain shape and a more uniform particle size, thereby improving the quality of the finished stone. Supply higher quality premium stone.

Granite Processing Solutions

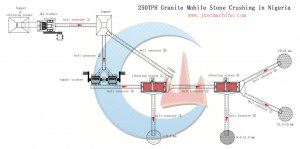

Saudi Arabia 200TPH Granite Crushing Line

250TPH Granite Crushing Plant Setup in Tanzania

80-100TPH Granite Stones Crushing Processing Line

200TPH Complete Granite Crushing Sand Making and Washing Plant

300-500TPH Stone Crushing Plant Suitable For River Stones, Granite & Marble

400TPH Complete Granite Crushing Plant For Indonesian Customer