JXSC has provided a “turnkey solution” for 120 TPD a lithium ore processing plant in Nigeria. The services in this plant we supplied include below:

- Mining project processing consulting at the beginning.

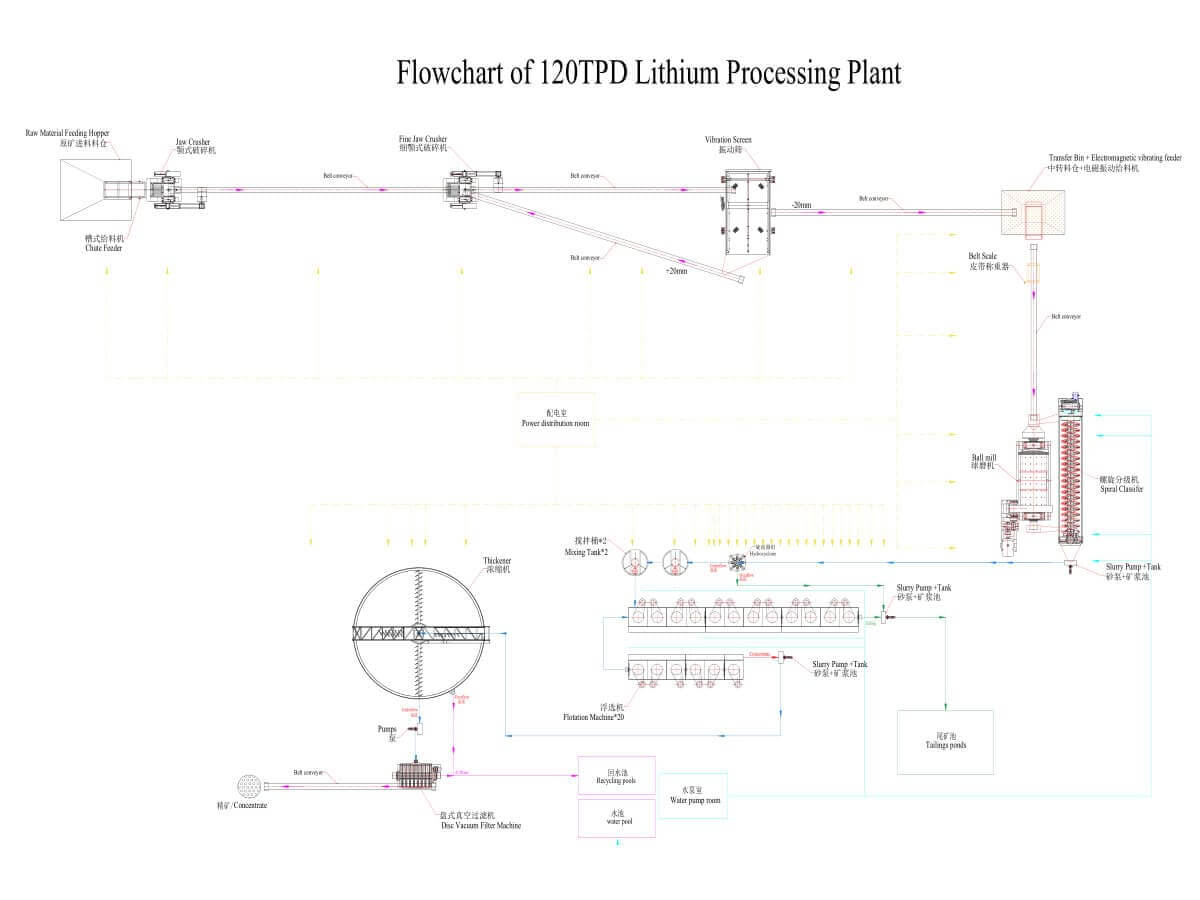

- Design and draw flowchart.

- Send the engineer to the mine site to check the mine and ore before starting.

- Provide complete set processing equipment.

- Dispatch engineer to customer’s mine site for guidance of equipment installation, commissioning, and training workers.