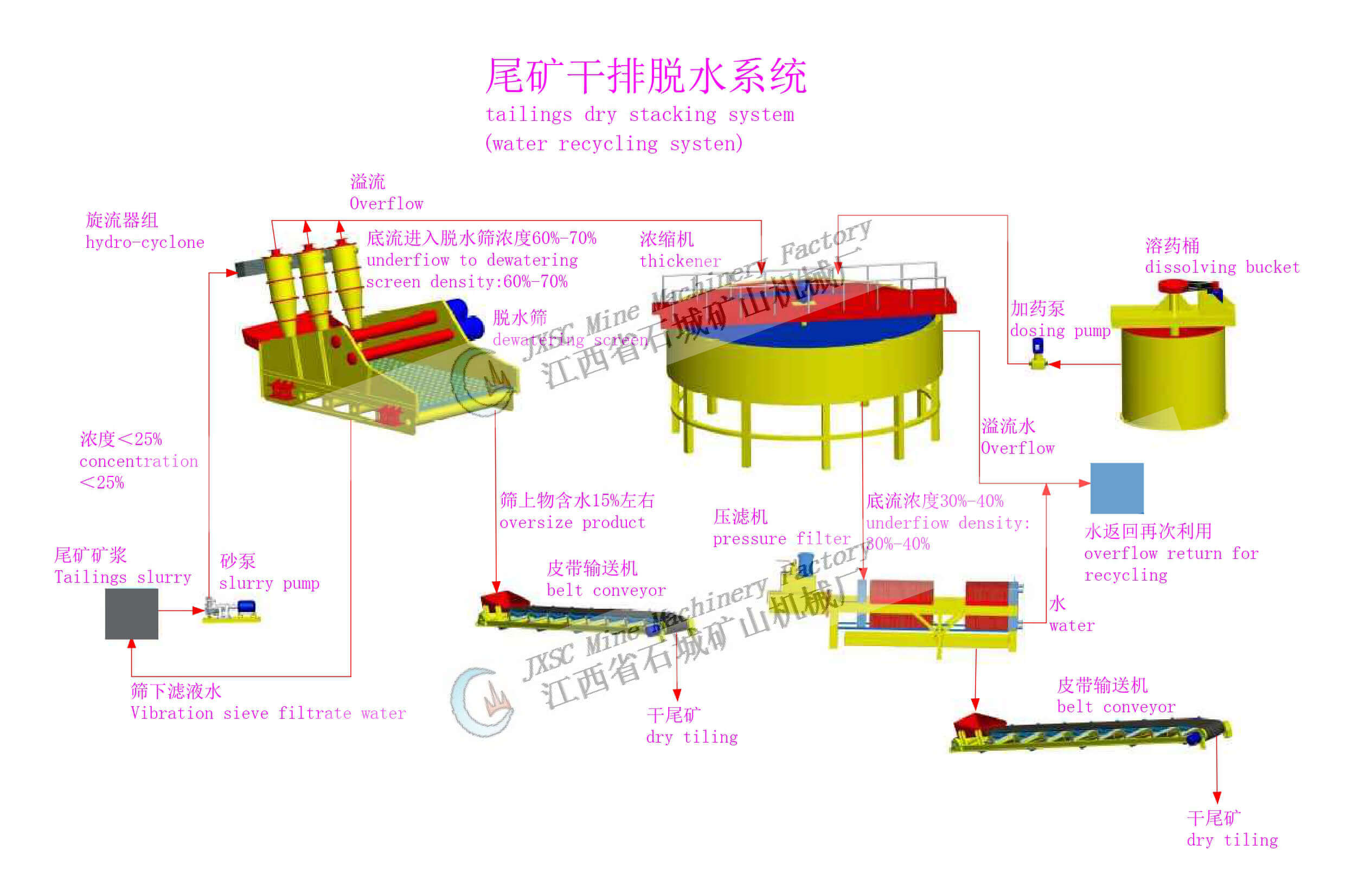

The dry tailings plant is a new process of tailings disposal, which means that the tailings slurry output from the beneficiation process is concentrated in multiple stages, and then processed by high-efficiency dewatering equipment such as dewatering vibrating screens to form low water content, easy precipitation, solidification, and utilization. The slag stored at the site can be transported to a fixed location for dry storage. Dry stack tailings management offers significant benefits in terms of environmental sustainability, process water recovery, and footprint of the tailings storage facility.

It is the essential technology of green mine that reach the aim of tailings dry stacking and avoiding environmental pollution. JXSC Mine Machinery Factory supplies dry tailings management solutions for the dewatering and concentrating of mineral tailings in the mineral processing plants. It designs process tailings filtration plants and manufactures the equipment, maximizing your solution to tailings emissions.