Manganese Ore Description

Manganese is a group VII B element in the fourth cycle of the periodic table. In nature, manganese has valence states II, III, IV, and VII, among which valence states II and IV are the most common. Manganese oxidizes easily in the air. Under heating conditions, powdered manganese can be combined with chlorine, bromine, phosphorus, sulfur, silicon, and carbon. Manganese has strong lithophile properties in the earth’s lithosphere and meteorites of silicate phase, but has strong oxyphile properties in the upper part of the lithosphere. Although manganese and iron have many similar chemical properties in the lithosphere and meteorites, manganese is not ferrophile. There are more than 150 kinds of manganese-containing minerals known in nature, including oxides, carbonates, silicates, sulfides, borates, tungstate, phosphates, etc.

Beneficiation method

The common beneficiation methods of manganese ore are mechanical beneficiation (including ore washing, screening, gravity separation, strong magnetic separation, and flotation), fire enrichment, chemical beneficiation, etc

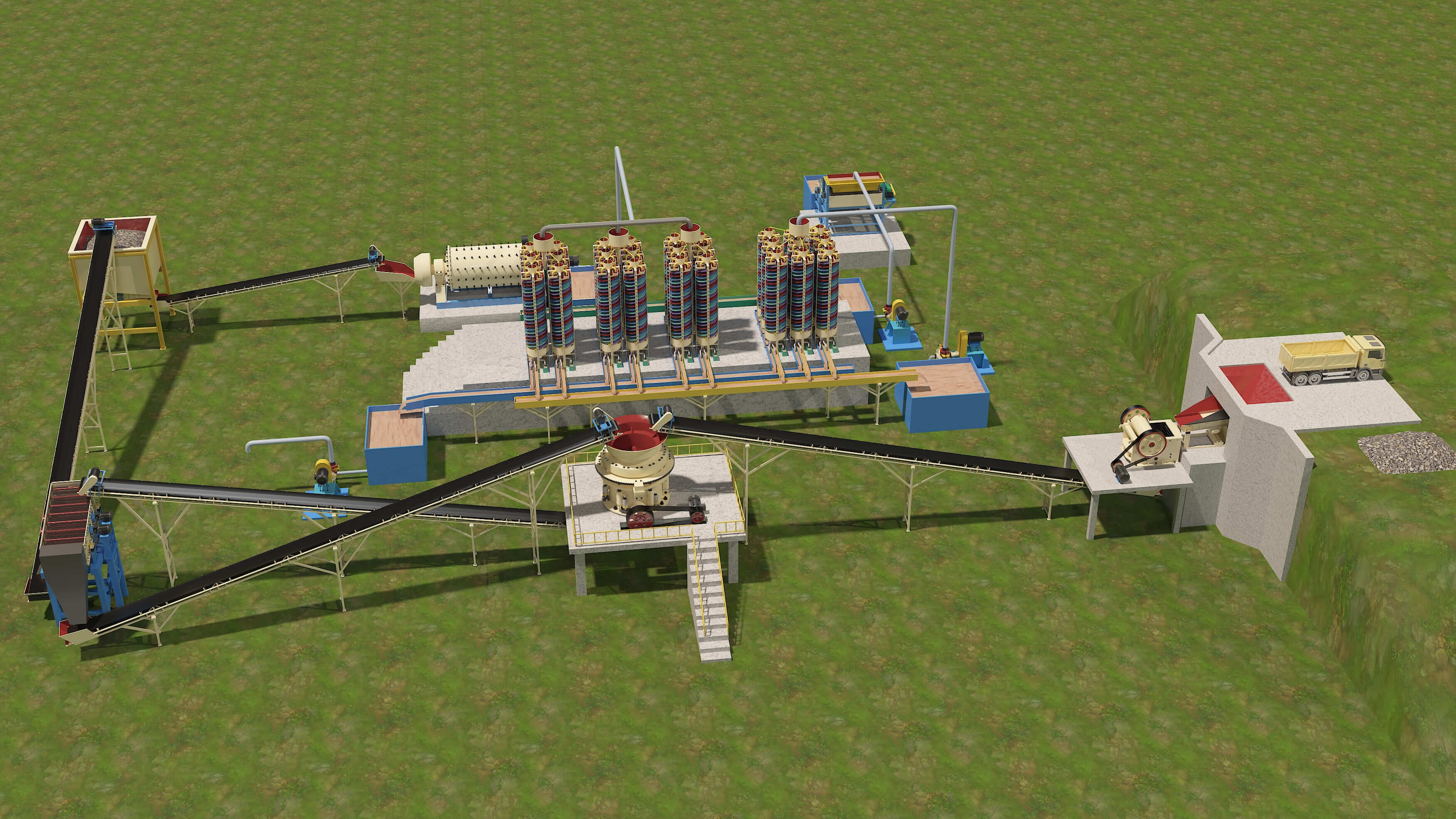

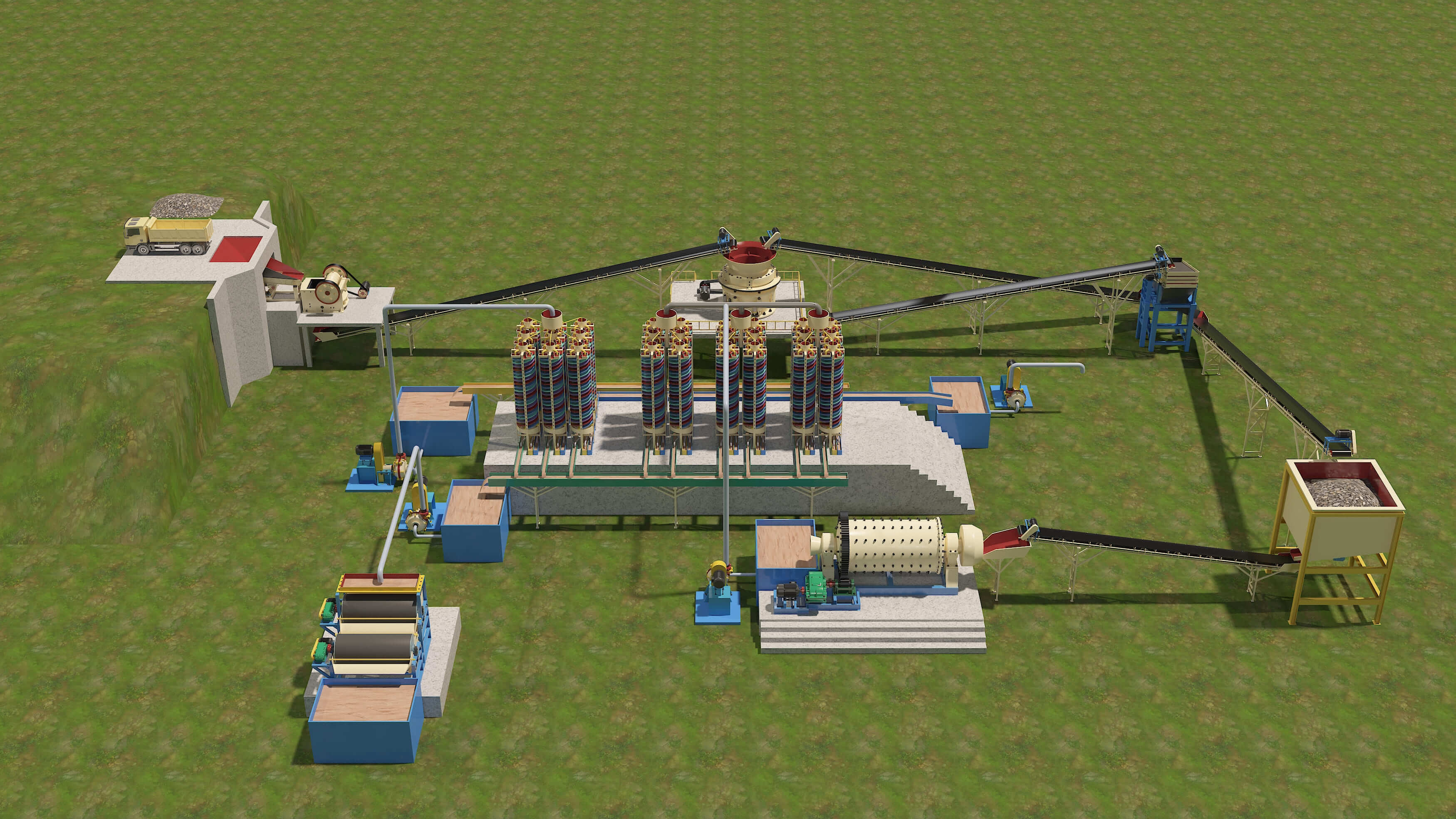

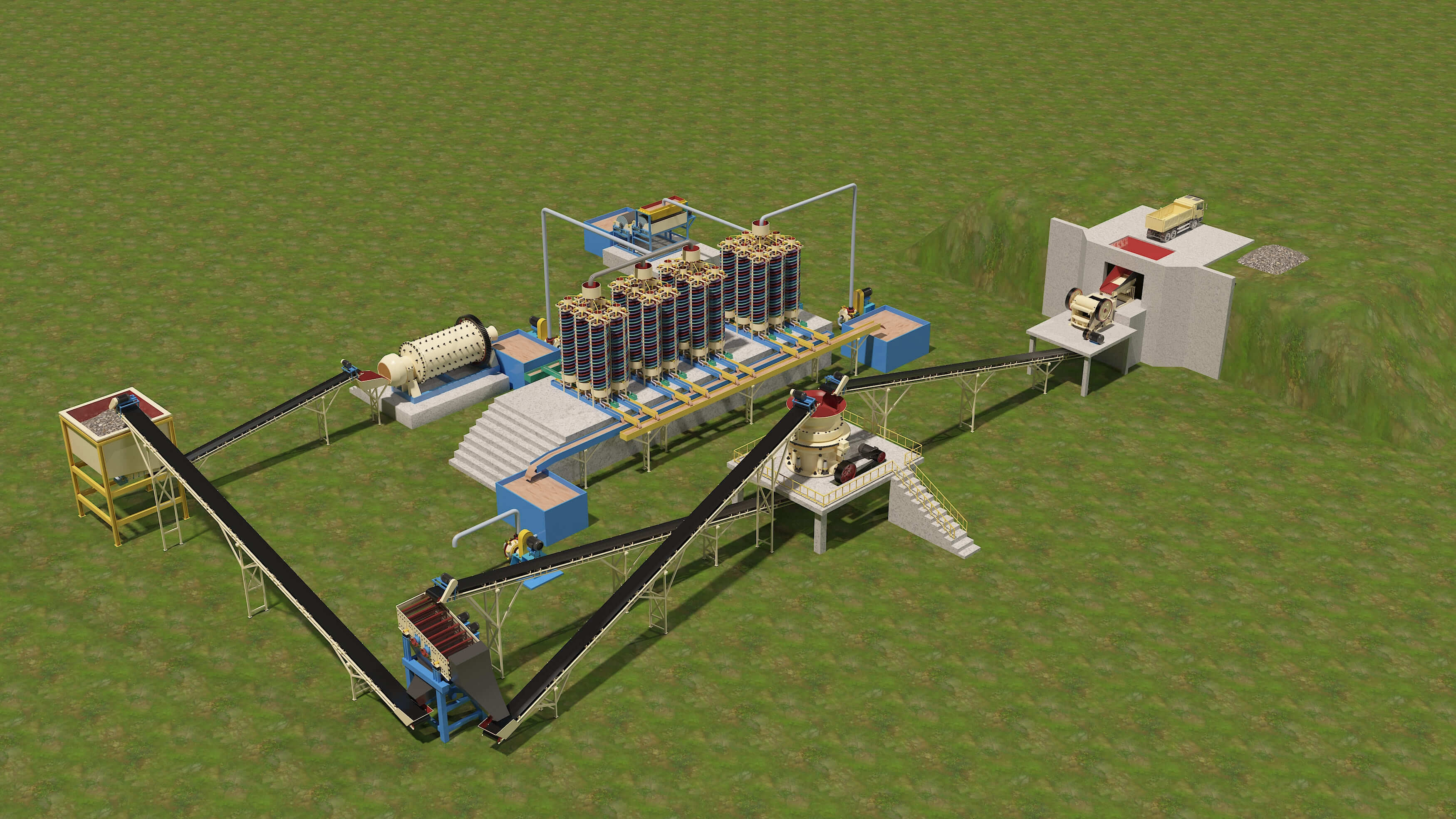

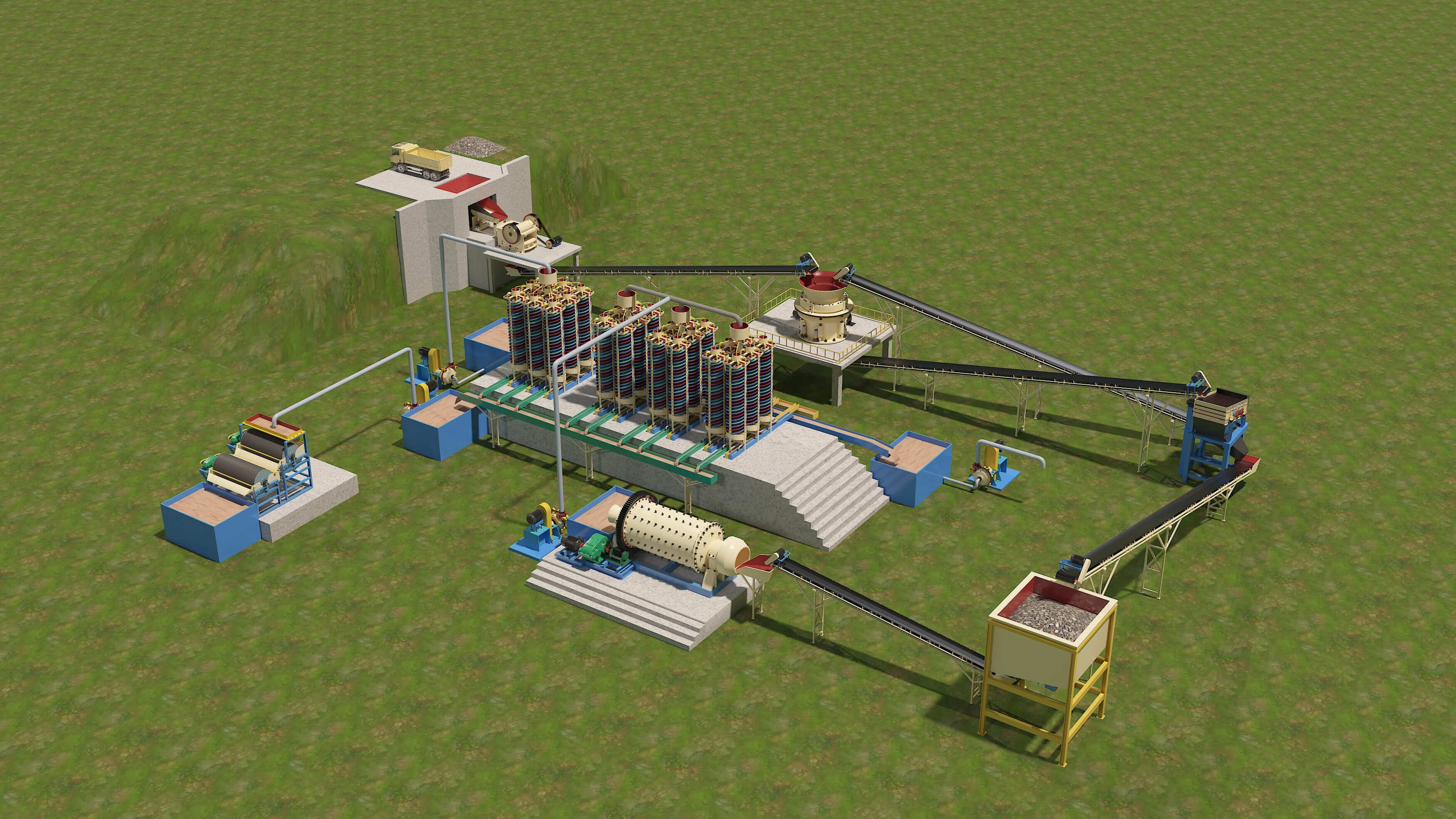

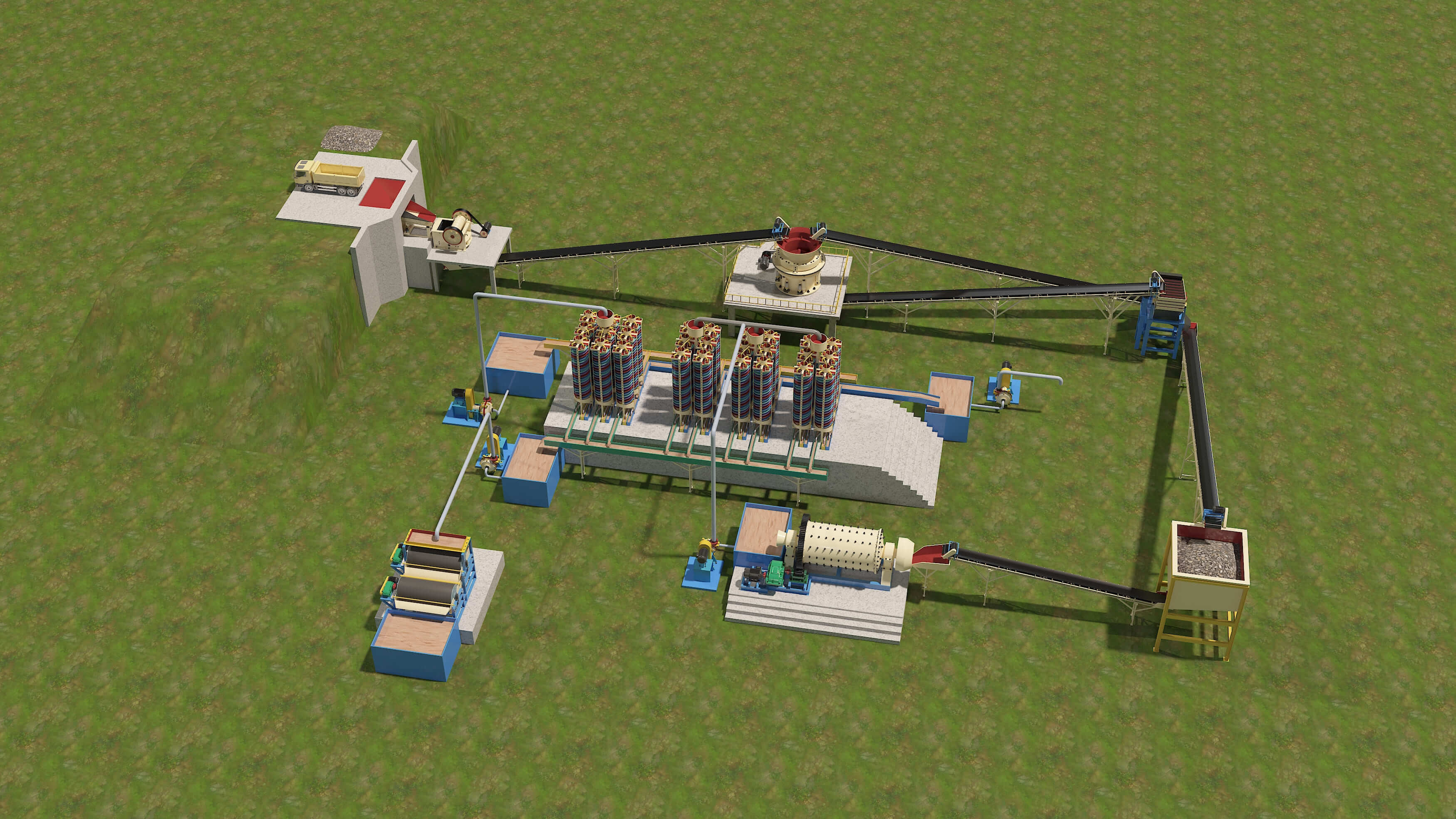

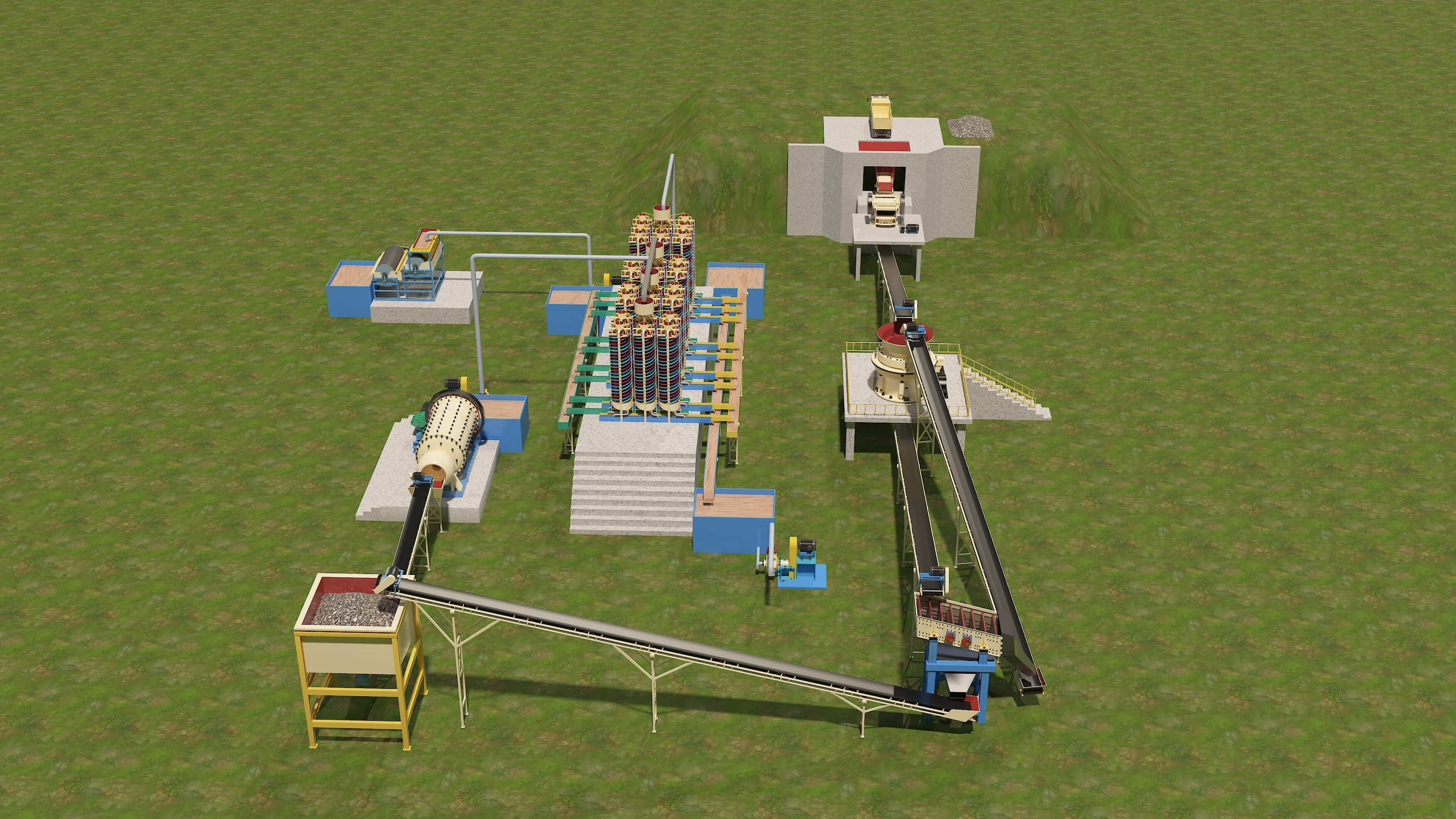

Manganese Ore Recovery Processing

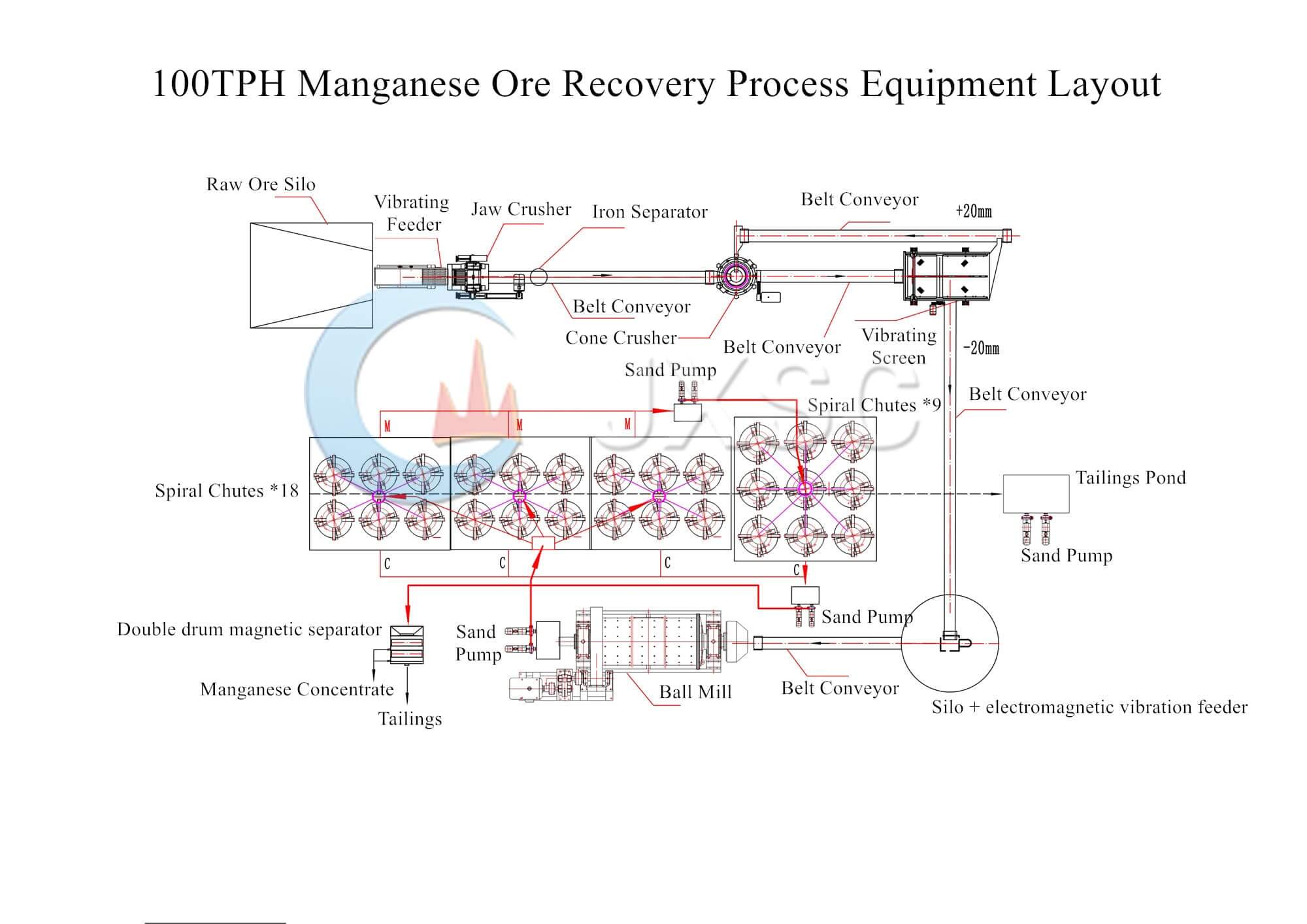

Flowchart Explanation

This setup is for the manganese ore process: raw bin+vibration feeder>jaw crusher>belt conveyor>cone crusher>belt conveyor>vibration screen>belt conveyor>hopper+electromagnetic feeder>belt conveyor>ball mill>slurry pump>spiral chute>slurry pump>double drum magnetic separator.

The raw bin+vibration feeder for feeding materials to the jaw crusher automatically, you only need to load the materials to the raw bin by truck or excavator or else as you want.

The jaw crusher is for crushing the raw ore into small pieces, then to the cone crusher to get the fine sizes.

The vibration screen for separating the size +20mm back to the cone crusher, 0-20mm will to the hopper+electromagnetic feeder, then to the ball mill.

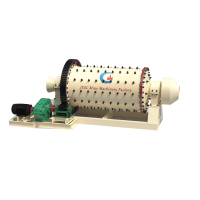

The ball mill is for grinding the 0-20mm materials to 0-1mm, then using the slurry pump to transport the 0-1mm materials to the spiral chute to separate the heavy minerals.

The double drum magnetic separator is for separating the manganese from other heavy minerals, making the manganese concentrate to a higher grade.

The capacity for this washing plant can be customized as per request such as 10tph, 50tph,100tph, etc.,

Notes: The belt conveyor from jaw crusher to cone crusher will need to add the iron remover to make sure the safe and efficient work of the cone crusher.

The spiral chute will normally make two phases, the concentrate from the first phase spiral chute will to the second phase to concentrate again, that will make sure a higher grade and also release the workload of the magnetic separator.