Type

Element (Minerals/Ores of)

Mineral Classification

Oxide

Chemical Formula

MnO2 (pyrolusite)

Streak

Black to bluish black

Mohs Hardness

2-6.5

Type

Element (Minerals/Ores of)

Mineral Classification

Oxide

Chemical Formula

MnO2 (pyrolusite)

Streak

Black to bluish black

Mohs Hardness

2-6.5

Crystal System

Tetragonal

Color

Darkish, black to lighter grey, sometimes bluish

Luster

Metallic, dull, earthy

Fracture

Uneven

—Manganese Processing Cases—

200TPH Rock Manganese Mining Plant in Zambia

Most manganese ore is a fine-grain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing. At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods (washing, screening, gravity separation, strong magnetic separation and flotation), as well as special beneficiation methods (fire enrichment, chemical beneficiation, etc.).

(1) Beneficiation process flow optimization. By strengthening the washing and sieving, gravity separation and coarse-grained magnetic preconcentration, optimize process flow. The coarse-grained magnetic separation and gravity separation preconcentration can increase the grade of manganese ore by 3% to 5%, which is especially suitable for manganese carbonate ore.

(2) Various types of strong magnetic separators. The successful application of DPMS permanent magnet strong magnetic separation machine, new type wet permanent magnet separator and other magnetic separators enables the effective recovery of manganese ore that could not be recovered or has poor recovery effect, which significantly improves the technical indicators of the concentrator. , achieved good economic benefits.

(3) SHP type strong magnetic separator and SLON type high gradient magnetic separator are applied in manganese ore, which significantly improves the selection effect of fine manganese ore, and provides an effective way for manganese recovery in manganese ore and tailings.

(4) Progress in the comprehensive recovery of polymetallic manganese ore.

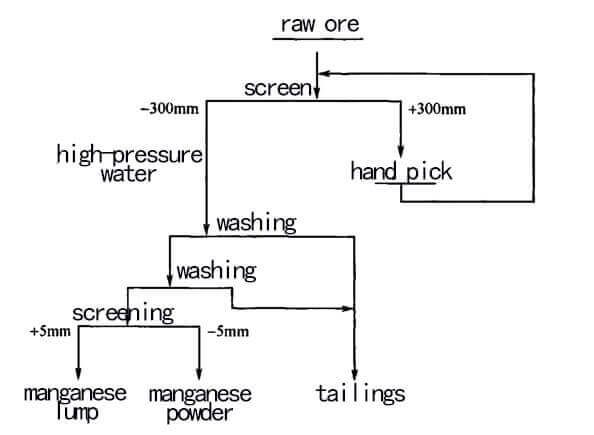

Washing is the separation of ore and mud under hydraulic, mechanical and self-friction action, which improves the ore grade. Main ore washing equipment includes ore trommel screen, cylinder trommel scrubber and tank washing machines.

The washing is often accompanied by screening, and the screen machine separates the cleaned ore into different sizes for use in a different area.

Gravity beneficiation is based on the difference in density and particle size of the mineral. The shape of the mineral particles affects the accuracy of sorting by density to some extent. Gravity separation can be used for concentrating, also for tailing processing and preconcentration. In addition, gravity separation generally consists of a combination process with magnetic separation and flotation.

The density of manganese oxide ore is generally about 3.7~3.9t/m3, which is significantly different from silicate type gangue. Commonly used gravity separators include mineral jigs, shaker table, cyclones, chutes, and the like.

The density of manganese carbonate ore is 3.3~3.6t/m3, which has a small difference from the density of gangue. It needs to be separated by heavy medium separators.

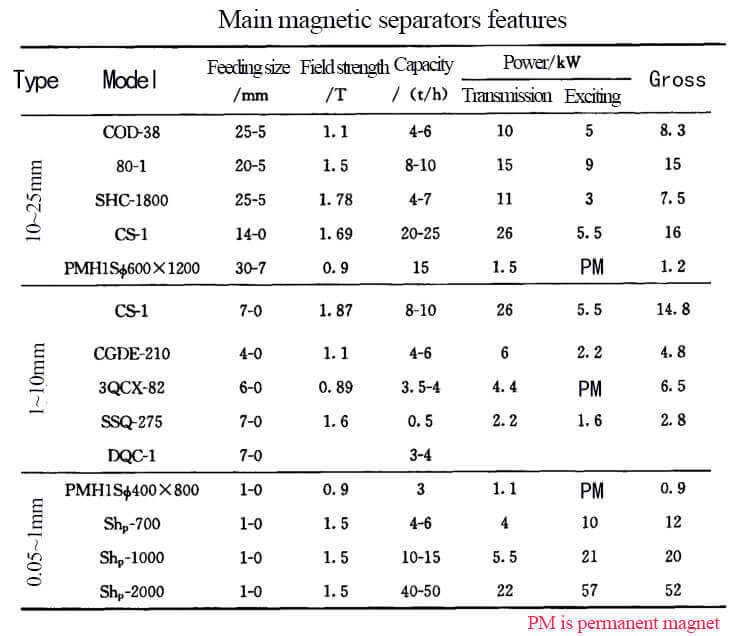

Manganese mineral is a weak magnetic mineral ( the specifical magnetization coefficient x=10×10-6~600×10-6cm3/g ), and it can be recovered in a strong magnetic field magnetic separator with a magnetic field strength Ho=800~1600kA/m (10000~20000oe), the manganese grade is increased by 4% to 10%.

The magnetic separators are easy to control, suitable for various manganese ore process. The most commonly used machine is the medium-grain strong magnetic separator, followed by the coarse-grained and fine-grained magnetic separators, the micro-grain-strong magnetic separator is still in the experimental stage.

10~25mm, using CGD-38 roll strong magnetic separator;

1~10mm, using CS-1, CS-2 series strong magnetic separators;

0.05~1mm, using ShP and SZC series strong magnetic separator.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.