This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant > Basalt Aggregate Processing

Basalt Processing Plant

Material: Basalt Rock

Application: Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

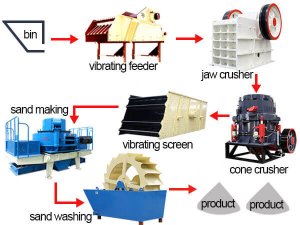

Equipment: Jaw crusher, cone crusher, sand making machine, vibrating feeder, vibrating screen, etc.

Basalt Introduction

Basalt is a kind of ore widely distributed in nature. Its hardness is medium to high, and the rock is hard and dense. Because of its strong and wear-resistant characteristics, it can be made into sandstone aggregate, and the finished product is an excellent aggregate. It can be widely used in construction projects, airport bridges, and other infrastructure.

Basalt’s Colors

Basalt is typically black or dark gray. This dark coloration is primarily due to minerals such as pyroxene and amphibole, which are rich in iron and magnesium. These minerals give basalt its characteristic dark appearance. However, it can also have brown, red, or green variations due to weathering or impurities.

Formation of Basalt

Basalt is a common extrusive igneous rock formed from the rapid cooling of basaltic lava. It is a dark-colored, fine-grained rock composed primarily of volcanic minerals such as pyroxene, plagioclase feldspar, and olivine. The cooling process of basalt lava is usually rapid, which results in the formation of small mineral crystals that give the rock its fine-grained texture.

Basalt Main Composition

The main compositions of basalt are silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide (and a small amount of potassium oxide, sodium oxide). Among them, the content of silicon dioxide is relatively large, and it’s about 45% to 50%.

Basalt Aggregate Processing - Sand-Making Plant

The process of processing basalt stones into sand aggregates generally has three steps.

1. Coarse Crushing

Large pieces of basalt stones enter the jaw crusher through the feeder through the conveyor belt, which can directly crush large basalt rocks into small stones.

2. Secondary Crushing

The stone material from the jaw crusher can not meet the use standard. Then it is transported to the impact crusher or cone crusher for secondary crushing and is directly made into 12, 13, 24 aggregates and other specifications required by crushed stones.

3. Sand Making

If machine-made sand is still needed, the crushed stone aggregate needs to be put into the sand-making machine again for fine crushing and shaping, and it can directly produce the machine-made sand below 5mm.

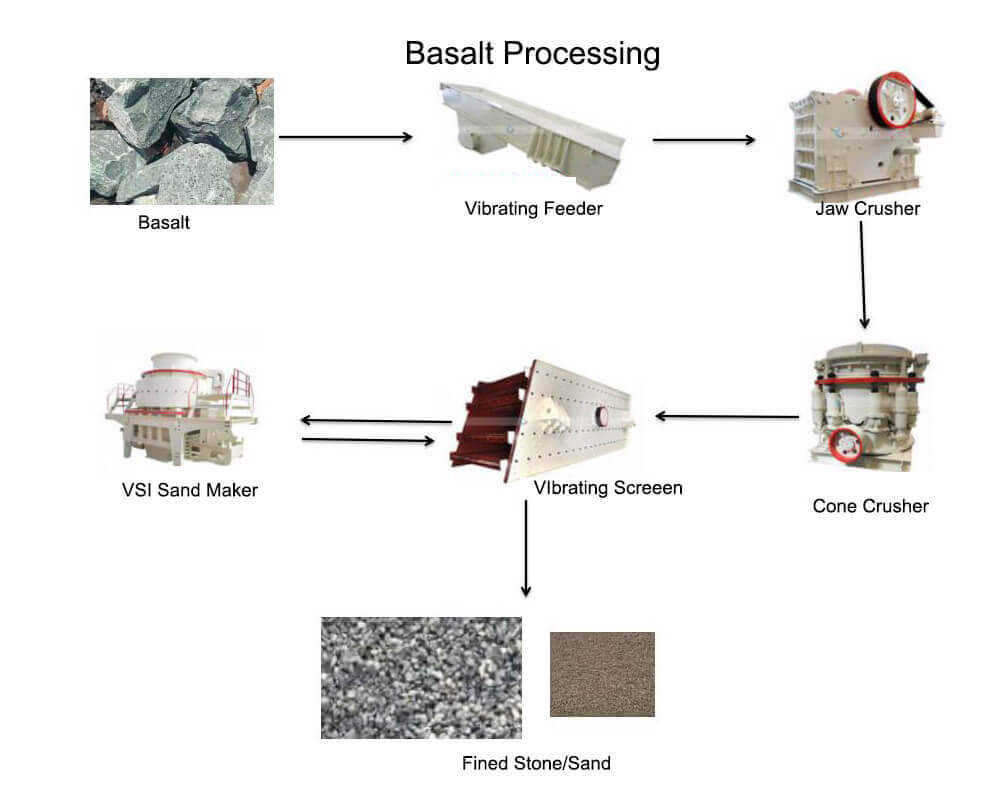

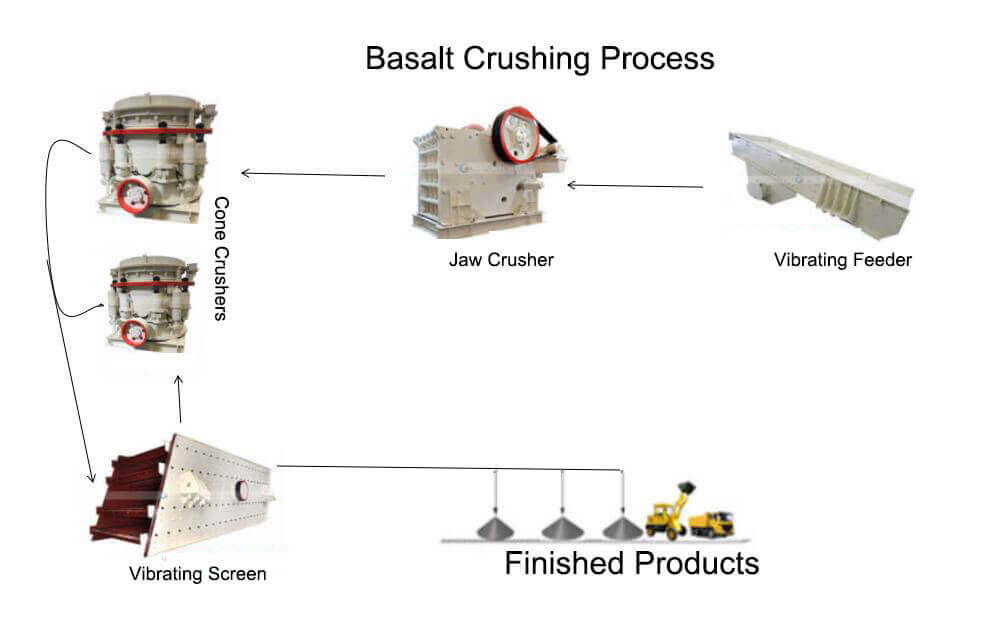

Basalt Crushing Process

Basic Process of Basalt Production Line

Use the vibrating feeder to send the basalt stone to the coarse jaw crusher for coarse crushing, and send the coarsely crushed material from the coarse crusher to the cone crusher for further crushing, then transport the crushed material to the vibrating screen for screening. The materials that meet the particle size requirements of the finished product are transported to the finished product stockpile by the belt conveyor. The materials that do not meet the particle size requirements of the finished product are returned to the cone crusher for the crushing process, forming a closed loop. The particle size of the finished product can be combined and graded according to users’ needs.

Basalt Processing Performance

- High degree of automation

- High crushing rate

- Low operating cost

- Energy saving and environmental protection

- The product has uniform particle size, good shape, and reasonable gradation.

The basalt production line determines according to rock hardness and customer requirements for product particle size. According to different production site conditions, JXSC provides customers with technological process solutions and technical support and can also design non-standard supporting parts according to customers’ actual installation conditions.