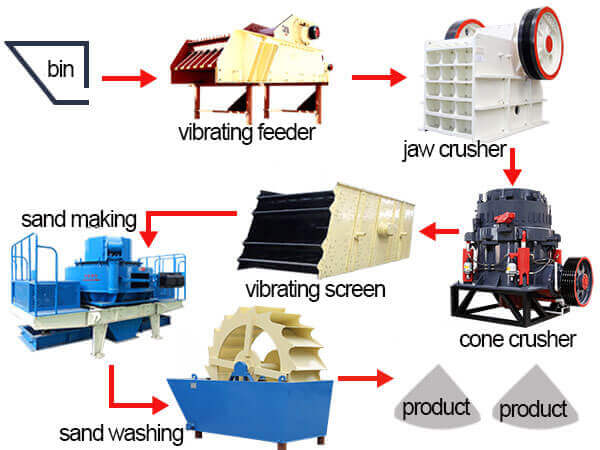

Most basalt processing plants adopt a three-stage crushing process to reduce overall operating costs.

1. Medium-small scale crushing plant, usually adopts ” two-stage jaw crusher +sand making machine “. primary jaw crusher and secondary jaw crusher can reduce the basalt size to below 60mm, third stage sand making machine to make the grain shape better.

2. Large scale crushing plant, usually adopts a ” jaw crusher + cone crusher + sand making machine ” layout. Cone crusher has lower wear cost, but need higher invest.

3. As for the basalt crushing production line with less strict grain size requirements, the third-stage crusher can be canceled.

Although the grain size is poor and the proportion of the needle-shaped stone is high, the running cost and the investment cost can be greatly reduced. Of course, the price of sandstone with poor grain size will be lower. As a railway track meteorite, it is generally not necessary to configure a counter-attack.

【Feed size】≦600mm

【Finished product specifications】0-5, 5-10, 10-20, 20-30, 30-50mm

【Related equipment】raw material warehouse, 490×110 vibrating feeder, PE750×1060 jaw crusher, B1000 conveyor×26m, 250 cone crusher, B1000 conveyor×28m, 2YK2460 vibrating screen, B1000 conveyor×30m , sand making machine, vibrating screen, B800 conveyor × 29 meters, B500 conveyor × 15 meters, B650 conveyor × 15 meters, B650 conveyor × 20 meters, B500 conveyor × 15 meters (3 units).

【Environmental protection measures】Closed production, effectively reducing dust pollution, in addition, the spray dust collector is equipped to effectively suppress dust.

【Investment estimation】USD $90,000

【Feed size】≦500mm

【Finished product specifications】0-5mm

【Related equipment】raw material warehouse, 380×95 vibrating feeder, PE600×900 jaw crusher, B800×25m conveyor, PEX250×1000 jaw crusher (4 sets), B800×20 m conveyor, sand making Machine, B800×27m conveyor, B650×28m conveyor, B800×15m conveyor.

【Advantages】Small crushing production line, low investment cost, small floor space, convenient disassembly and transportation, and remarkable energy-saving and environmental protection effects.

【Investment estimation】USD $50,000

【Feed size】≦500mm

【Finished product specifications】0-5, 5-10, 10-20, 20-30mm

【Related equipment】mobile jaw crusher, mobile impact crusher, mobile sand making machine

【Environmental protection measures】Closed production, effectively reducing dust pollution, in addition, the spray dust collector is equipped to effectively suppress dust.

【Investment estimation】USD $180,000

Above are some common basalt crushing production lines. If you are interested in, welcome to contact us online and will provide you with a satisfactory solution.

JXSC is a well-known crusher manufacturer in China. With more than 20 high-tech patents, JXSC is a veritable high-tech enterprise.

We produce a full set of basalt crushers, including jaw crusher, impact crusher, cone crusher, VSI impact crusher, vibrating screen, etc. In addition, we design the effective production line according to the actual situation to ensure safety and productivity.