JXSC has supplied a full set crushing plant and gravity beneficiation/ flotation separation plant for the 20TPH Rock Tungsten Ore Processing plant to our Korean customer.

This tungsten processing plant can handle 20 ton per hour capacity. The raw material appears in the stone type. the wolfram minerals contain arsenic.

JXSC Mine Machinery Factory has designed the flowchart according to customer’s tungsten ore plant and arrange chief engineer Mr.Lee to the mine site for equipment installation and commissioning guidance.

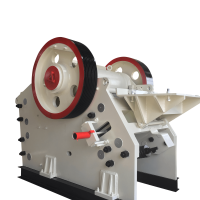

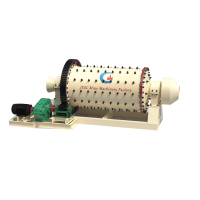

Tungsten mining process equipment

1) 1 set jaw crusher: for crushing big size stone into a small stone

2) 1 set ball mill: Grinding small stone to fine material minus 1 mm

3) Spiral chute: Rough concentrate heavy minerals after ball mill

4) gold shaking table: the concentrate ore from spiral chute will go to shaking table for separation

5) flotation cell: Use flotation to remove arsenic

Tungsten processing flow

The mined tungsten ore is initially crushed by jaw crusher, and after being crushed to reasonable fineness, it is uniformly fed into a ball mill by a hoist and a feeder, and the ore is crushed and ground by a ball mill. After the ball mill grinding fine ore into the next process: classification, spiral classifier by the proportion of different solid particles in the liquid precipitation rate of different principles, to wash the ore mixture, classification. When the washed and classified mineral mixture passes through the magnetic separator, the magnetic material in the mixture is separated by magnetic force and mechanical force because of the different specific magnetization coefficient of various minerals. After the initial separation of mineral particles after magnetic separators are sent to the flotation machine, according to different mineral characteristics to add different drugs, so that the desired minerals and other substances separated. After the desired mineral is separated, because it contains a large amount of water, it must be initially concentrated by a thickener and then dried by a dryer to obtain the dried mineral.

You may have an interest in Tungsten ore processing overview.

JXSC has rich experience in designing tin processing plant capacity varies from 10TPH to 200TPH, also suit for lead zinc mining, manganese mining.