Mobile Gold Wash Plant

【Capacity】1-300TPH

【Application】 Dryland, beachside, stream, river gold mining, etc.

【Services】Mining process flow design, quick machine selection, quotation, on-site installation, one-year warranty.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

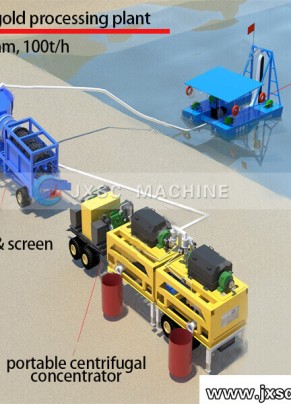

【Description】The portable gold wash plant integrates ore mining and gold mineral processing operation, including the excavation system, mineral processing equipment, water supply system, tailings treatment system, power supply, etc. JXSC’s small and portable/mobile gold wash plant with Trommel is fully customizable & moveable.

【Type】The configuration of the mobile gold wash plant varies with the ore nature, processing capacity, site environment, and other factors.

- Hard rock gold deposit, alluvial gold (placer gold) deposit.

- Dryland placer gold, river gold (need gold dredger), river bed & beachside gold.

- Contains sticky clay, sludge, a gold trommel wash plant equipped with a trommel scrubber, and a sand washing machine.

Equip with the sluice box, gold centrifugal concentrator, shaker table, gold trommel, sand washing machine, vibrating feeders, vibrating screen, pumps, and the like portable mining equipment according to different conditions.

Using a bulldozer and excavator stockpile the gold-bearing gravels near the gold mining wash plant, feed gravels into the wash plant from the feeding hopper (mount a vibrating screen to primary classify the gold-bearing gravels), the oversize material slides out, and the undersize material is mixed with water flow through the gold concentrator machines like gold centrifugal concentrator, portable shaker table, portable sluice box, tailings are discharged routinely.

【Portable gold wash plant manufacturer】JXSC has supplied gold mining equipment for large-scale and small-scale mining plants since 1985, developing deep cooperation relationships with gold mine companies in South Africa, Australia, Ghana, Russia, Congo, etc. Contact us to get the best gold wash plant price.

Product Structure

【Mobile/Portable Gold Washing Plant Structure】

1. Feeding: Dredge pump, hopper feeder with vibrating grizzly bar.

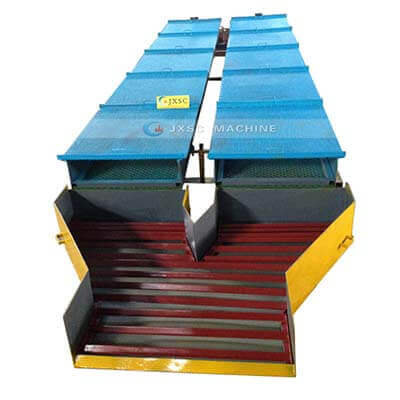

2. Washing and screening: Usually use a rotary scrubber, gold trommel, sand washing machine, vibrating screen, etc.

3. Beneficiation: Gold centrifugal concentrator, shaker table, sluice box, mineral jig.

4. Water supply

5. Tailings

6. Mobile System: Composed of chassis and traction steering two major components, 4 axes 16 tires, 4 mechanical legs support centrifuge, can be turned in situ 180 degrees, easy to move to the workplace.

【Mobile Gold Wash Plant Working Principle】

1. Dry gold mining

Dryland mobile gold wash plant with rubble tire, easy to move on, can separate placer gold from ancient river, dry beach sand. Dryland gold mining usually uses a trommel screen that combines the small gold jig and sluice box into a single mobile gold recovery plant to process placer gold, and monomer lode gold. This type of small-scale gold wash plant has lightweight, easy to maintain, and low-cost.

2. River gold mining

The river gold panning equipment, mostly as the gold dredging ship floating on the water, is a multifunctional placer mining equipment that combines excavation, ore washing, beneficiation, tailings disposal, and power supply, water supply. River gold dredgers can work at streams, rivers, offshore, beachside, etc.

But as for small gold wash plants, the cost of the gold dredger may be a huge part. How to build a small gold wash plant? Using a dredge pump pumping the river bed fine sand to the nearby land portable gold trommel, wash and classify the undersize material to the gold centrifugal concentrator and shaker table.

Technical Parameters

| Machine | Model | Capacity | Feeding size |

| Gold washing trommel | JXSC-900 | 40 tons per hour | 150-200mm |

| Gold centrifugal concentration | STLB60 | 8-12 tons per hour | 3mm |

| Sluice box | 1*6 m | 20 tons per hour | 3-15mm |

| Shaking table | LY2100 | 500 kg per hour | 2mm |

Configured Devices

|  | |

|  |

Our gold washing plant includes a feeding system, clay process system, screening system, power system, and gold recovery system(coarse/fine). Contact us to get the optimal configuration scheme.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.