Hydraulic Separator

【Processible Material】 Gold, chrome, tin, coltan, diamond, tantalite, silica sand

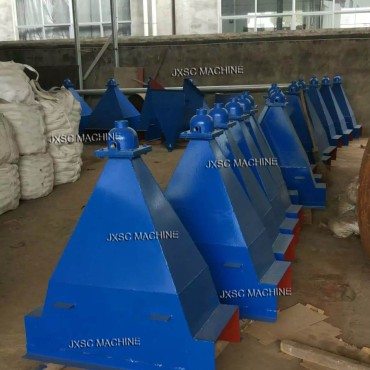

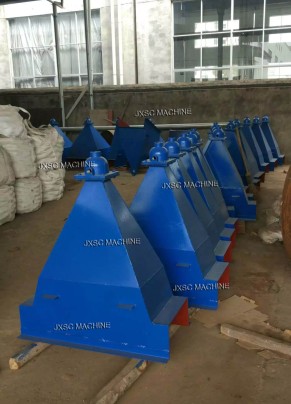

The hydraulic classifier tank is an iron pyramid tank installed with a wedge-shaped sand stopper strip on the top and a valve at the bottom.

Generally, it is connected by common water tanks for classification tanks of a series width from 200 mm to 800 mm. Settling sand is discharged from coarse to fine.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Application】

The hydraulic separator tank is extensively applied to hydraulic classification operation before table sorting to play the role of grading and distributing a number of ores to improve the sorting efficiency of the table, which boasts such merits as simple structure, easy maintenance, no power consumption, reliable performance, easy operation and so forth.

A hydrogen classifier can be used for washing clay minerals. As an auxiliary operation, it can be used for pre-classification, inspection classification, control classification of the grinding cycle, or dewatering and desliming. It is also the primary means of checking the composition of fine-grained materials (e.g., water out).

There are mechanical stirring hydraulic classification boxes, cone-shaped hydraulic separators, classification boxes, and sieve-plate trough hydraulic classification boxes in common use.

Hydrogen classifier has the advantages of simple structure, no need for mechanical power, small height, easy configuration, low sediment content, water-saving, and high sand concentration. It is commonly used in tungsten concentrators for mine classification before shaking table separation.

Find other mineral classification machines.

Product Structure

【Hydraulic Separator Working Principle】In the working process of the hydraulic classification box, the basic movement form of ore particles is a settlement. For example, in an ascending medium flow, if the settling velocity of the mineral particles equals the velocity of the ascending water flow, the mineral particles will be suspended. This is also the critical state in which the mineral particles float or sink. The size of the mineral particles is called the critical size or separation size. The ore particles whose settling velocity is less than the ascending velocity will be washed out by the current and become overflow, and the ore particles whose settling velocity is greater than the ascending velocity will sink and become sand.

Technical Parameters

| Model | YX-200 | YX-300 | YX-400 | YX-600 | YX-800 |

| The number of blocking sand bar | 11 | ||||

| Sand barrier strip length(mm) | 180 | 280 | 380 | 590 | 790 |

| Drainage pipe diameter(mm) | 25 | ||||

| Rising water pressure(kg/cm2) | 1.0-2.0 | ||||

| Feed Size(mm) | 2.0-3.0 | ||||

| Feeding Concentration(%) | 20-25 | ||||

| Water Consumption(m/t) | 2.0-3.0 | ||||

| Outer Dimensions (mm) | 800×200×1000 | 800×300×1000 | 800×400×1000 | 800×600×1000 | 800×800×1000 |

| Weight (kg) | 0.107 | 0.124 | 0.148 | 0.178 | 0.214 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.