XMB Laboratory Rod Mill

【Capacity】:300-5000 g/h

【Feed Size】: <3mm

【Application】:Mainly used for laboratory wet grinding of fine ore and other materials, mineral feasibility study and for heavy concentrate reduction.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

XMB Laboratory Rod Mill is an efficient laboratory grinder for laboratory wet grinding of fine ore or other material flow, general materials can also be used as dry grinding. A small, light, multi-purpose grinding equipment. The steel rods and steel balls can be interchanged to be used as a ball mill or rod mill. This rod mill has a large amount of ore grinding at one time, and electric cylinders control the output. There is no need for manual operation, and steel balls can also replace steel rods. Generally, this rod mill should be used when carrying out experimental research on ore selectivity and manual heavy ore sand grinding of fine ore. It can also be used for grinding fine ore in metallurgy, geology, the chemical industry, building materials, etc. Rod ball mill has the advantages of high efficiency, large grinding capacity and uniform particle size.

It is commonly used in laboratories for supporting the use of single-cell flotation machines or other lab flotation machines with corresponding specifications, as well as other equipment It is a supported ideal laboratory grinding equipment. At present, according to different grinding media, grinding equipment can be divided into rod mill, ball mill, gravel mill, self-mill and so on. JXSC laboratory mining equipment, which has a long history and a mature manufacturing technology, is widely used in production practice and laboratory.

【Features】

- Electric control of feeding and discharging, convenient and fast, and the tilt angle can be set arbitrarily;

- Copper core motor is adopted, with sufficient power, low working noise, and the running time of the machine can be set arbitrarily;

- Made of thickened steel, with strong stability and long service life;

- The particle size composition of the finely ground material is relatively uniform, the degree of over-grinding is small, the efficiency is high, and the energy consumption is small;

- The transmission mechanism is simple, reliable, less lubricated and easy to maintain;

- Use and installation do not require foundation or workbench, easy to move, small footprint.

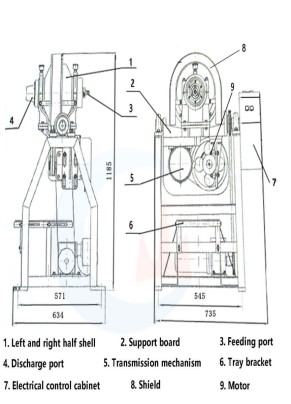

Product Structure

【Structure】

It mainly comprises handle, barrel, discharge screw, frame, powerful motor, bracket and other parts. The right end of the cylinder has a plug for the ore port, and the left end has a cover for the ore discharge port. When working, use a wrench to tighten the compression bolt in a clockwise direction, so that the sealing rubber pad on the ore discharge port cover is closely connected with the end surface of the cylinder to play a sealing role. When discharging ore, turn the compression bolt counterclockwise.

【Working Principle】

The cylinder body and the large belt pulley are connected as a whole with screws. One end of the cylinder is an opening, and the other is a hollow shaft: the two ends are respectively supported on a pair of supports and a main bearing. The bottom bearing housing and support frame are mounted on the support frame and can be rotated 180°. The support plate is mounted on the frame with two bearing housings. The support plate is mounted on two bearing housings on the rack. The turntable can rotate around 22.5°, 67.35° and 90° horizontally. The ore feeding, discharge, rod removal, and anti-rust liquid filling can be completed by controlling the handle and aligning the plate.

The support board can be deflected by 22.5°, 67.35°, and 90° from the horizontal to the left and right by rotating the handle and positioning plate to complete the actions of ore loading, ore discharge, pouring rods and filling anti-rust lime water. When the rod mill is working, tighten the bolt clockwise with a special wrench until the discharge cap of the rubber gasket is tightened three or four turns. The cover is withdrawn to the outside by 6 ~ 10 mm, and the ore can be discharged by removing the cover.

Technical Parameters

| Item | XMB160*200 | XMB200*240 | XMB240*300 | ||||||||

| Drum(Diameter×Length) (mm) | 160×200 | 200×240 | 240×300 | ||||||||

| Volume (L) | 4.02 | 7.5 | 13.57 | ||||||||

| Capacity (g) | 300~800 | 500~1000 | 1000~5000 | ||||||||

| Feed Size (mm) | -2 | -2 | -3 | ||||||||

| Discharge Size (mm) | -0.074 | -0.74 | -0.074 | ||||||||

| Drum Speed (r/min) | 120 | 110 | 96 | ||||||||

| Motor(Kw) | Model | A02-7114 | y801-4 | y801-4 | |||||||

| Power | 0.25 | 0.55 | 0.55 | ||||||||

| Speed ( r/min) | 1400 | 1390 | 1390 | ||||||||

|

Grinding Media |

Steel Rod | Diameter (mm) | 18 | 20 | 15 | 18 | 22 | 15 | 18 | 22 | |

| Length (mm) | 185 | 225 | 286 | ||||||||

| Qty (pcs) | 10 | 9 | 17 | 9 | 9 | 33 | 13 | 6 | |||

| Weight (kg) | 3.55 | 4.09 | 4.9 | 4.2 | 4.9 | 12.79 | 7.48 | 5.02 | |||

|

Steel ball | Diameter (mm) | 20 | 25 | 30 | 20 | 25 | 30 | 20 | 25 | 30 | |

| Qty (ea) | 100 | 26 | 5 | 136 | 52 | 29 | 290 | 115 | 37 | ||

| Weight (kg) | 3.31 | 1.70 | 0.56 | 4.4 | 3.3 | 3.7 | 9.57 | 7.37 | 4.1 | ||

| Dimensions(L×W×H) (mm) | 1052×530×1150 | 1052×615×1160 | 1052×615×1160 | ||||||||

| Weight (kg) | 90 | 155 | 160 | ||||||||

| Drum(Diameter×Length) (mm) | 160×200 | 200×240 | 240×300 | ||||||||

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.