Cone crusher is one of the most widely used mining equipment. This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one.

JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit. Get to know our cone crusher machine product page, discuss with us the model and price.

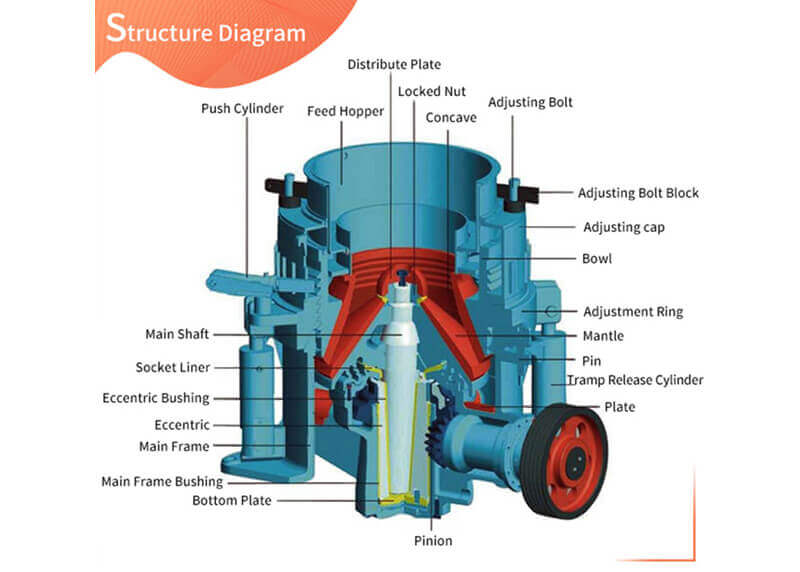

Simmons cone crusher

【Application】 Simmons cone crusher as a medium crusher or fine crusher used in the site where not require high granularity standard.

Since the Simmons cone crusher controls the product size by reducing the size of the discharge opening, it is not suitable for use for superfine crushing and sand-making operation.

【Advantages】 low price, stable performance, experienced in use and maintenance.

【Disadvantages】 In terms of structure, it is much heavier than the single-cylinder hydraulic cone crusher of the same specification, coupled with small crushing force, low output, Simmons cone crusher is gradually replaced by effective laminating crushing hydraulic cone crusher.

【Development】 On the basis of the original Simmons cone crusher, the Chinese cone crusher manufacturer added a hydraulic clearing chamber function, which is called a compound cone crusher.

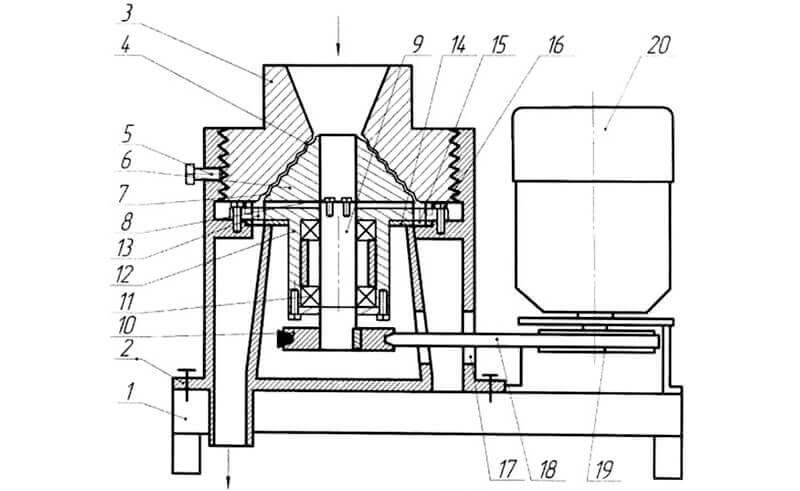

Gyratory cone crusher

【Application】 The gyratory cone crusher is suitable for the fourth stage of medium-hard materials crushing. Its special crushing cavity shape can do laminating crushing, obtain a small product granularity even in the large discharge size.

Therefore, the rotary cone crusher is also often called the superfine crusher.

【Advantages】 Qualified grain size and good shape. Rotary cone crushing not only provides the mill with finer-grained raw materials but also important equipment for sand making plant.

【Disadvantages】 High energy consumption, heavyweight and low output. With the development of high capacity, the rotary cone crusher will gradually be replaced by the hydraulic cone crusher.

Single cylinder hydraulic cone crusher

【Application】 The single-cylinder hydraulic cone crusher is suitable for medium hardness crushing, fine crushing, and even ultra-fine crushing.

【Advantages】 Simple structure, low manufacturing cost and stable performance.

Steep cone, high swing frequency, small eccentricity, simple structure, easy automatic control, small crushing force and power fluctuation.

Small eccentric angle of the main shaft, and long crushing chamber, which improves the uniformity of the crushed material. The product has a uniform particle size and less needle-like material.

【Disadvantages】 The crushing force of the single-cylinder hydraulic cone crusher is slightly insufficient, especially for crushing hard materials.

Lifting moving cone, if the feeding is uneven, the rolling wall is not evenly worn.

The cylinder is at the bottom, the lower working space is small, which brings certain difficulties to maintenance.

Multi-cylinder hydraulic cone crusher

【Application】 The multi-cylinder hydraulic cone crusher has large crushing force and is suitable for crushing hard materials. The material smaller than the discharge mouth can even account for 70%~80% of the processing amount.

【Advantages】 High swing frequency, large eccentricity, slow cone, multi-cylinder hydraulic locking around, the main shaft is cantilever beam support form and spherical tile support structure, using hydraulic motor to adjust the fixed cone.

【Disadvantages】 Small spherical radius R, and small swing radius easy cause unstable phenomena such as moving cone swaying, overturning, poor contact between the main shaft and the bushing, which affect the normal operation of the machine.

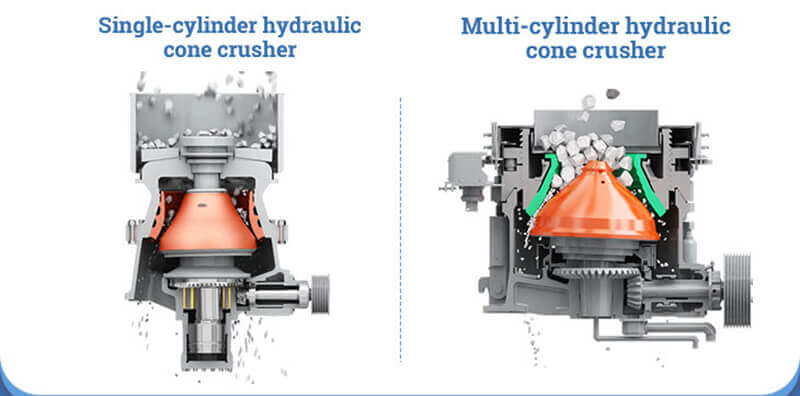

Single-cylinder VS multi-cylinder hydraulic cone crusher

In terms of crushing performance, in general, the multi-cylinder hydraulic cone crusher is higher, its crushing force and crushing ratio are larger, the discharge adjusting range is wider, greater flexibility in adjusting the product grade.

It is superior to single-cylinder cone crusher in the performance and quality of crushed products. However, whether single or multiple cylinders are used in the entire process depends on the entire process layout.

The multi-cylinder hydraulic cone crusher is used to reduce the number of crushing stages and reduce investment. The needle-like content is generally below 15%.

Crush hard rock, choose multi-cylinder hydraulic cone crusher; crush general hardness rock, choose single-cylinder hydraulic cone crusher.

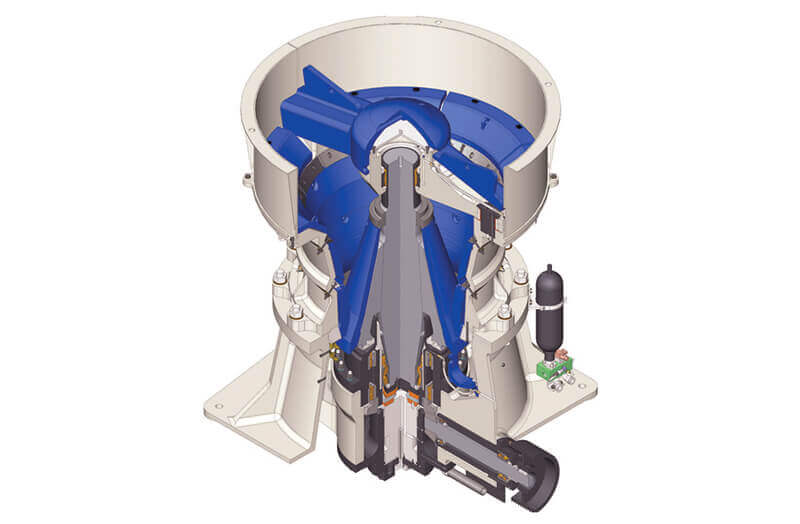

Inertia cone crusher

【Application】 The inertia cone crusher has a large crushing ratio and can obtain very fine-grained products. It is used for ultra-fine crushing or artificial sand making, and the effect is better than other types of cone crushers.

【Advantages】 The working principle of the inertia cone crusher is unique. It is a new type of ultra-fine detail crushing equipment with a good “layer pulverization” effect. The open-circuit crushing product has a granularity of millimeters, which can meet the requirements of “multi-breaking and less grinding” new technology, greatly reduce the energy consumption and steel consumption of the grinding process.

【Disadvantages】 Heavy, it weighs about twice as much as other cone crushers.

In short

The above comparison of the performance and characteristics of various types of cone crushers can be used as a reference for crushing equipment selection.

After the machine type is selected, the specific specification size and quantity are selected according to the configuration relationship with other devices and the variation of the load rate to achieve the expected production target.

JXSC is a 35 years Chinese mining equipment manufacturer, supply different types of rock crushers for mine, sand plant, construction industry.

Hot products: Jaw crusher, cone crusher, impact crusher, hammer crusher, roller crusher.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…