Lithium is an essential strategic resource widely used in emerging fields such as batteries, ceramics, glass, aluminum, lubricants, refrigerants, nuclear industry, and optoelectronics. It is an indispensable raw material for modern high-tech products.

Lithium Ore Beneficiation Equipment

Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, and auxiliary equipment to form a complete production line.

Lithium Ore Beneficiation Methods

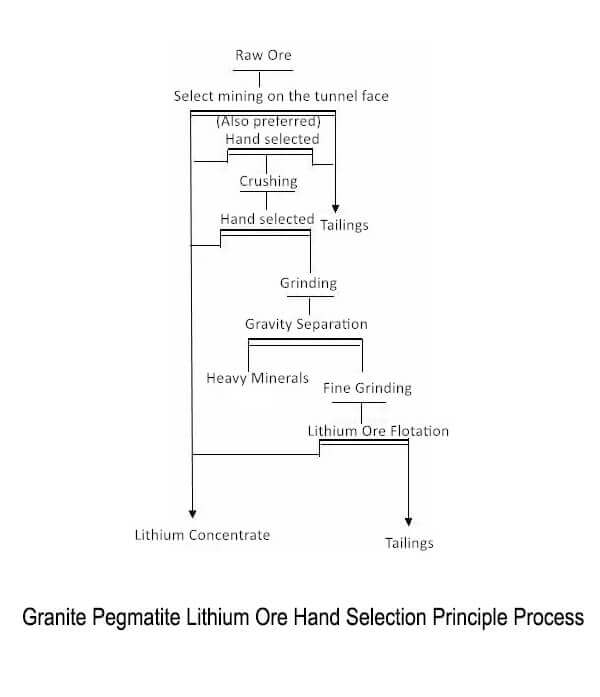

1. Manual Selection Method

The manual(hand) selection method is a sorting method based on the differences in color and appearance between lithium minerals and gangue minerals. The sorting particle size is generally 10 to 25 mm. The determination of the lower limit of the sorting particle size depends on the economic benefits. Hand selection is the earliest beneficiation method used in the history of lithium ore production. The United States used this method as early as 1906 to produce spodumene concentrate from the pegmatite deposits in the Black Hills area of South Dakota. In addition to spodumene, hand selection is used to make lithium concentrates such as lepidolite, feldspar, and spodumite.

Due to high labor intensity, low production efficiency, poor beneficiation index, and enormous resource waste, flotation or other methods have generally replaced hand selection. However, hand selection is still a way to produce coarsely embedded lithium ores in areas with cheap labor—an essential process for producing lithium concentrate.

2. Flotation method

There are two different processes for spodumene flotation: positive and reverse flotation.

- The positive flotation process is the preferential flotation of spodumene. Its essence is: after grinding the fine ore in an alkaline medium formed by sodium hydroxide or sodium carbonate, high concentration, strong stirring, multiple washings, and desliming, Add fatty acids or soaps as collectors to directly flotate spodumene.

- The reverse flotation process uses regulators such as dextrin and starch to suppress spodumene in an alkaline medium adjusted by lime and a cationic collector to float the silicate gangue minerals as foam. The product in the tank is spodumene concentrate.

Hand selection and flotation are the main methods for selecting spodumene. Other techniques, such as thermal cracking, magnetic separation, and gravity separation, play an auxiliary and secondary role in spodumene concentrate production.

3. Thermal cracking mineral processing method

The thermal cracking mineral separation method is used to select spodumene ore. This method is based on the fact that when natural spodumene is roasted at about 1100°C, its crystals change from α-type to β-type. At the same time, the volume expands and is easily broken into powder. Therefore, selective grinding and screening are used to obtain spodumene and gangue separation. This method has been used in Canadian processing plants and laboratories in China and the Soviet Union. China’s mineral processing workers once conducted experiments with raw ore containing 1.58% Li3O. They were first roasted at 1050°C for one hour, then cooled and placed in a rubber ball mill for selective grinding. Finally, they were screened with a 150-mesh sieve. The results obtained a 4.9% Li2O concentrate grade under the screen, and the recovery rate was 74%.

Two points must be paid attention to when applying the thermal cracking mineral processing method:

- Control the roasting temperature around 1100°C. When the temperature is too high, the mica in the ore will sinter; when the temperature is too low, the transformation of spodumene from α to β type is incomplete.

- The ore cannot contain many minerals that are easy to melt when roasted or other minerals with thermal cracking properties, otherwise the purpose of separating spodumene will not be achieved.

4. Heavy medium mineral processing method

Since there is little difference in density between spodumene and associated gangue minerals, the usual gravity separation methods, such as jigging, spiral beneficiation, and shaking table beneficiation, are unsuitable for separating spodumene ores. However, heavy media or liquid beneficiation is an effective separation method for spodumene ore. The over-gravity medium beneficiation method has been used to produce lithium mines in South Dakota and North Carolina in the United States. In a concentrator in South Dakota, -200 mesh ferrosilicon is used as a weighting agent to prepare a medium with a density of 2.7 g/cm3, and a heavy medium cone concentrator is used to select 3.3~3.8 mm spodumene ore in the plant. As a result, the grade of spodumene concentrate produced reached a 5.31% Li2O operation recovery rate of 78%. In addition to the heavy media cone concentrator, the Gold Mountain Mine in North Carolina also uses a heavy media cyclone to select spodumene with a finer particle size range. In addition, the mineral processing personnel of the U.S. Bureau of Mines also used tetrabromoethane as a heavy liquid (density 2.9529 g/cm3) to conduct continuous tests of heavy liquid cyclone separation of spodumene ore and achieved quite satisfactory results. The ore particle size is -35 mesh, containing 20% spodumene. The resulting concentrate contains 92~95% spodumene, with a recovery rate of 86~89%. The heavy liquid recovery rate is above 95%. Years of practice have shown that as long as there is good protection, Tetrabromoethane can be used on a large scale.

5. Magnetic separation method

Magnetic separation is usually used as an auxiliary method to improve the quality of spodumene concentrate. For example, the spodumene concentrate produced by flotation at the Gold Mountain Concentration Plant in North Carolina, USA, contains high iron content and can only be sold as chemical-grade concentrate. To meet the requirements of the ceramic industry, the plant uses magnetic separation to remove iron. In addition, since lepidolite has weak magnetism, magnetic separation can be used as the primary method for producing lepidolite concentrate.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…