Lithium ore resource is a kind of metal energy with various uses. It is essential in manufacturing, such as glass, ceramics, and batteries. In addition, it is also used in high-energy lithium batteries and controlled thermonuclear reactions. It is an essential raw material for mankind to solve long-term energy supply.

Global Lithium Mine Types

Global lithium mines are divided into three types: salt lake brine lithium mines, pegmatite lithium mines, and sedimentary lithium mines. Pegmatite and sedimentary lithium mines are solid lithium mines among the distribution types. Judging from the development status of the three lithium mineral resources, salt lake brine-type lithium minerals have high development and utilization rates and play an essential role in the production of lithium compounds.

Lithium Ore Ball Mill Types

Lithium resources are mostly extracted from pegmatite ores and salt lake brine. Extracting lithium from brine is simple, with a high recovery rate, low cost, and little environmental pollution. However, currently, lithium resources in salt lake brine are gradually depleted. Extracting lithium from pegmatite ores has become an essential resource for obtaining lithium resources. There are many methods to extract lithium minerals from this type of ore, such as sulfuric acid roasting, sulfate roasting, chloride roasting, etc. However, it can’t lose a vital link – grinding before extraction.

The mineral processing link can effectively extract lithium resources by grinding the pegmatite lithium ore after the ball mill achieves monomer dissociation. Currently commonly used lithium ore ball mills include grate ball mills, overflow ball mills, long barrel ball mills, energy-saving ball mills, etc.

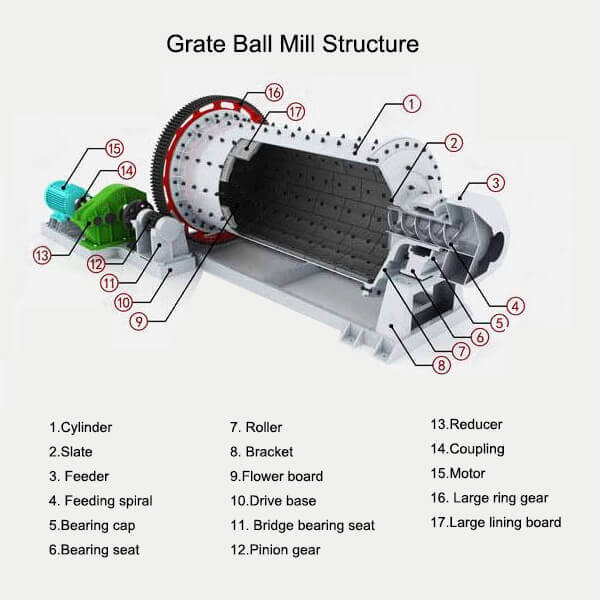

1. Lithium ore grate ball mill

In lithium ore dressing plants, grate ball mills are mainly responsible for grinding coarser minerals and are mostly used in one-stage grinding operations. Due to its unique ore discharge plate design, the ball mill has a large ore discharge particle size and less grinding blockage.

The grate ball mill is a horizontal cylindrical rotating device with an outer edge gear transmission and two chambers. The material enters the first chamber of the mill evenly and spirally from the feeding device through the feeding hollow shaft. The chamber has a ladder or corrugated linings, and steel balls of different specifications are installed inside. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height. Then it falls, causing heavy impact and grinding effect on the material. After the materials reach coarse grinding in the first chamber, they enter the second chamber through the single-layer partition plate. This chamber has a flat lining plate and contains steel balls for further grinding the materials. The powdery material is discharged through the discharge grate plate to complete the grinding operation.

The grate ball mill comprises the feeding part, the discharging part, the rotating part, the transmission part (reducer, small transmission gear, motor, electronic control), and other main parts. The hollow shaft is made of cast steel with a removable inner lining. The rotating gear is hobbing from castings. The cylinder is inlaid with a wear-resistant lining plate with good wear resistance. The grate ball mill runs smoothly and works reliably. Due to the existence of the grid plate, the grate ball mill can be loaded with more balls and is convenient for loading small balls. The productivity of the lattice ball mill is about 20% to 30% higher than that of the overflow ball mill.

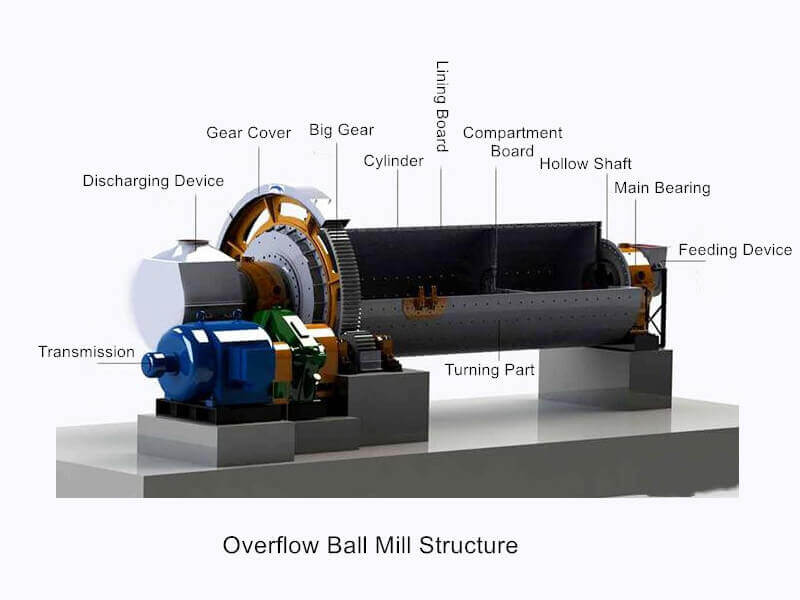

2. Lithium ore overflow ball mill

This type of ball mill differs from the grate ball mill because there is no grid plate design at the ore discharge area. When discharging ore, it mainly relies on the continuous feeding of ore slurry to crowd out the ground ore slurry so that it gradually moves to the ore discharge section. When the slurry exceeds the overflow weir, the slurry is discharged. Overflow ball mills are mainly suitable for grinding finer minerals in lithium ore dressing plants and are primarily used in the second stage or concentrate grinding operations.

The overflow ball mill is a type of ball mill commonly used as a grinding machine in mineral processing plants. It mainly comprises a cylinder, end cover, main bearing, hollow journal, transmission gear, and ore feeder. The barrel of the overflow ball mill is welded with a steel plate with a thickness of 15-36mm. Cast steel flanges are welded to both ends of the barrel. The end cover and the flange are connected with bolts. The two must be Finely machined and fitted as the hollow journal carrying the mass of the grinder is welded to the end cap. There are 1-2 manholes on the cylinder for inspection and lining replacement. Lining plates are laid inside the barrel and end cover. The main bearing supports the hollow journal on the end cover. The main bearing is commonly used as a sliding bearing with a large diameter but short length. The bearing bush is cast with Babbitt alloy. It differs from ordinary sliding bearings in that only the lower half has a bearing bush. The entire bearing is cast iron except the bearing bush is cast with babbit gold.

When the ball mill is working, the material is loaded into the cylinder through the hollow shaft at the feed end of the ball mill. When the ball mill cylinder rotates, the grinding body is attached to the cylinder lining plate and removed by the cylinder due to inertia, centrifugal force, and friction. It is thrown down due to gravity when brought to a certain height. The falling grinding body crushes the materials in the cylinder like a projectile. The material enters the first warehouse of the ball mill evenly and spirally from the feeding device through the feeding hollow shaft. The warehouse has a ladder or corrugated linings, and steel balls of different specifications are inside. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall. , producing a heavy impact and grinding effect on the material. After the materials reach coarse grinding in the first warehouse, they enter the second warehouse through the single-layer partition board. This warehouse has a flat lining plate and steel balls for further grinding the materials. The powdery material is discharged through the discharge grate plate to complete the grinding operation.

3. Lithium ore long barrel ball mill

The barrel of the long-cylinder ball mill is long and much larger than the diameter. The inside of the barrel can be set up in 2 or multiple chambers (generally at most four rooms). The length of each chamber is determined according to the grinding conditions. This ball mill is used in lithium ore dressing. It can be used in the factory for fine-grinding operations.

4. Lithium ore energy-saving ball mill

The energy-saving ball mill is developed and innovated based on the original grid or overflow ball mill. It changes the transmission device of the traditional ball mill in the past and is equipped with a slow-speed transmission device, which can reduce the overall energy consumption of the ball mill by about 30%; in addition, It is equipped with a spray lubrication system for large and small gears to reduce the problem of poor lubrication effectively; it is equipped with a hydraulic jacking device. During the maintenance of the ball mill, it can manipulate the handle of the hydraulic station to raise and lower the hydraulic jack to ensure the horizontal position of the ball mill. Customize the ball mill lining plate with suitable properties according to the lithium ore to ensure the ball mill’s wear resistance and extend the ball mill’s service life.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…