Introduction

The main component of barite is barium sulfate, which has very important uses in oil, chemical and other industries.

The proportion of primary barite ore is not enough to meet industrial requirements. Most of the raw barite ore needs to go through processes such as crushing, screening, jigging, and dehydration. For barite ore with a large amount of mud, additional washing process is needed.

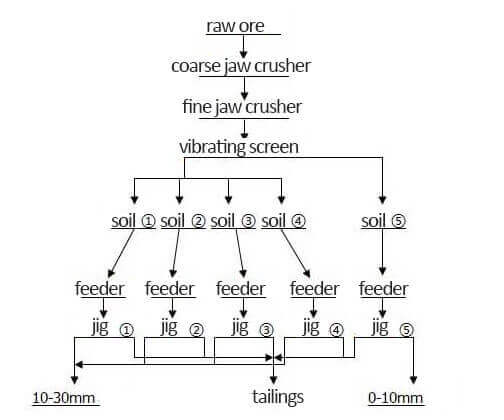

The principle of the barite jigging machine process

According to the specific gravity difference between the barite and its associated gangue, the barite is stratified according to the specific gravity in the vertical alternating water flow generated by the jigger. The barite with a larger specific gravity settles faster in the vertical alternating current and gradually deposits in the lower layer of the jigger sorting tank, while the gangue minerals with a smaller specific gravity gather in the upper layer of the sorting tank. These two minerals with different proportions are concentrate and tailings.

80TPH barite jigging process flow

① Crushing

The jaw crusher is mainly used to crush the mined barite to reach the size range of the jig machine.

Two-stage crushing process

It is recommended to use PE400*600 jaw crusher for the first stage of crushing, and PEF250*1000 fine jaw crusher for the second stage of crushing. After one stage of crushing, the product is conveyed to the second stage fine-jaw crusher through a belt conveyor to be crushed again to meet the selected particle size requirements of the subsequent sorting equipment. Since the customer requires no dust in the production process, it is recommended to add water in the crushing process to reduce the dust generated when the crusher is working.

② Screening

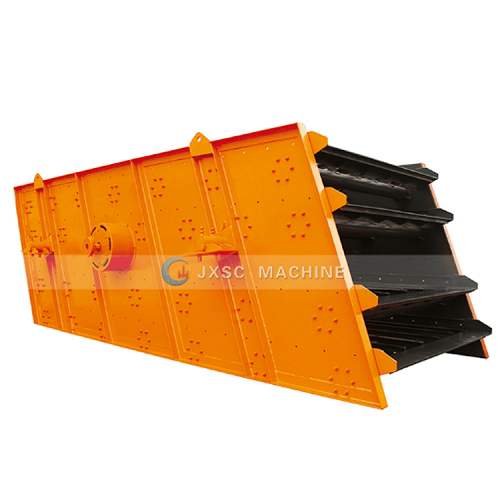

Jigging machine sorting has strict requirements on the size of the material. Generally, it is required to be classified to achieve a better beneficiation index and higher processing capacity. Therefore, a screening process is required in the barite gravity separation process. The crushed products are divided into different grades to enter the jig machine for jig separation.

The screening equipment adopts a circular vibrating screen with large processing capacity and high screening efficiency. This type of vibrating screen has low failure rate, large processing capacity, high screening efficiency and easy operation. It is an ideal equipment for barite ore screening. Since the screening process will also produce a certain amount of dust, it is recommended to also set up water in the process to reduce the generation of dust.

③ Feeding

The jig machine needs a uniform and stable feeding amount, so a silo and a vibrating feeder are usually set before the jig machine. The vibrating feeder adopts GZ3 electromagnetic vibrating feeder.

Our factory can produce combined detachable silo.

④ Jig separation

Due to the inevitable production of fine-grained materials during the crushing process, we use two types of jigs to separate the coarse and fine materials of the crushed barite.

AM30 jig machine, used to process 10-30mm coarse-grained barite ore. 2LTC-6109/8T jig machine, processing 0-10mm fine grained barite ore.

The concentrate produced by the jigs ①-④ flows into the 10-30mm granular concentrate pool through pipes or chutes, and the concentrate produced by the jigs No. ⑤ flows into the 0-10mm granular concentrate pond. All the tailings produced by the jig are collected into the tailings pond and transported away by forklift after precipitation.

⑤ Dehydration

Since the customer requires mechanical dehydration, simple precipitation dehydration can be used in the dehydration process. The mechanical dehydration scheme can also be designed according to the requirements.

⑥ Water circulation

The water consumption of jigs is relatively large, so it is generally operated by circulating water. Design the water circulation plan according to the specific conditions of the customer site.

Barite processing equipment

| Equipment | Model | Qty | Notes |

| Jaw Crusher | PE400*600 | 1 | With the motor |

| Jaw Crusher | PE250*400 | 1 | With the motor |

| Jaw Crusher | PE250*1000 | 1 | With the motor |

| Impact Crusher | PF1007 | 1 | With the motor |

| Vibrating screen | YZ1545 | 1 | Deck |

| Jig | 2LTC-6109/8T | 1 | – |

| Jig | AM30 | 4 | |

| Belt conveyor | – | – | According to site |

| Feeder | GZ3 | 5 | for 2LTC-6109/8T jig |

| Silo | 25m2 | 1 | for jig |

| Silo | 15m2 | 4 | for AM30 jig |

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…