The gold ore process is usually determined by the physical, chemical and mineralogical properties of gold ore and gangue. For example, gold ore with a large difference in specific gravity and coarse grain size is generally treated by gravity separation.JXSC gravity separation equipment mainly includes spiral chute, jig and shaker. The principle of re-election equipment basically follows the gravity sedimentation effect. The spiral chute blades are lined with wear-resistant rubber, which has strong wear and corrosion resistance, but the life of ordinary chute equipment is 4 -6 times, which reduces operating costs. the difference in wettability of mineral surface Large or dilute gold ore with fine grain size is generally treated by flotation separation method.The flotation equipment mainly includes a flotation machine and auxiliary equipment (stirring tank, drug feeder, etc.). In general, flotation machines are mostly standard equipment, and flotation auxiliary equipment is mostly non-standard equipment. The flotation machine is a device that directly completes the flotation process.

For some complex refractory gold ores, in order to maximize gold recovery and recycle other useful ingredients, it is technically necessary to choose a multi-process joint process, which is economically justified.

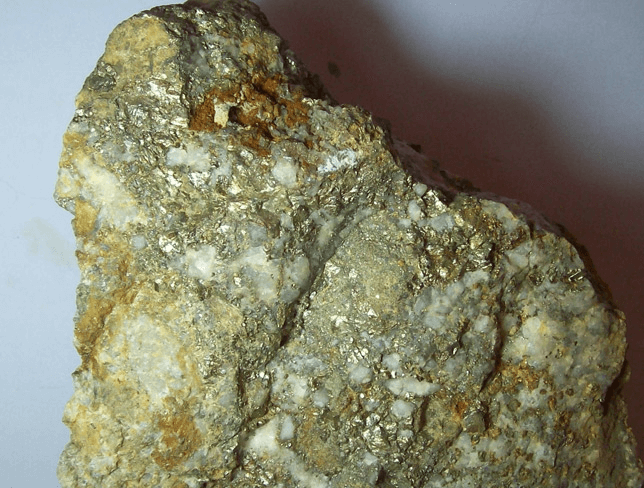

There are two main types of common gold ore: quartz vein type gold ore and sulfide gold-bearing ore ‘Jiangxi shicheng Mine machinery factory’. as a relatively mature China gold selection technology, its technicians give the following two kinds of ore commonly used Process.

Quartz vein type gold ore:

The quartz vein type gold ore beneficiation process is mainly cyanidation method and flotation method. The cyanidation method is a method in which gold or silver in gold or silver ore is leached by using an aqueous solution of an alkali metal cyanide as a solvent, and then gold and silver are extracted from a solution containing gold or silver. The extraction of gold and silver by cyanidation mainly includes cyanide leaching and deposition extraction steps. The cyanide leaching process includes two methods: tank leaching cyanidation and heap leaching cyanidation. The deposition extraction method has zinc addition method. (Zinc wire replacement method and zinc powder replacement method), activated carbon adsorption method (carbon slurry method CIP and carbon leaching method CIL), ion exchange resin method (resin slurry method RIP and RIL), electrolytic deposition method, magnetic carbon method, and the like.The determination of the process mainly depends on the particle size of gold and the symbiotic relationship with other minerals. In the case of contaminated or thin film free gold on the surface of the ore, a part of the gold can be recovered by jig separator re-selection to reduce the tailings grade and reduce the cyanide leaching time.

When the ore floatability is good, the quartz ore-bearing gold ore flotation can produce tailings treated by the cyanidation process, and the flotation tailings can be floated and then floated to improve the flotation recovery rate. In most cases, cyanidation is more common in quartz vein type gold ore. The main considerations are ore grinding fineness, cyanide concentration in the slurry, and leaching time. At the same time, in order to reduce the amount of cyanidation work, a process of re-cyanation of flotation concentrate can be employed.

Sulfide-containing gold ore

Most gold-bearing sulfide ore can be treated by flotation, and some can be treated by cyanidation, or by a combination method, or by amalgamation, re-election or a combined process.

The choice of flotation or cyanidation process depends on the recovery rate of gold, the comprehensive utilization of associated minerals, etc. If the ore contains more coarse gold, it must be pre-selected Because coarse gold is more difficult to dissolve in cyanide solution

and the flotation method is also difficult to recycle. When the surface of the gold particles is clean and there is no harmful component in the ore, the amalgamation method is better than the gravity separation method. In the production practice, the commonly used gold-containing sulfide ore dressing process is: first flotation, flotation concentrate can be directly cyanidated, or can be cyanated after grinding, or by gravity separation and amalgamation.

For the gold mining plant, try to adopt a mature, simple and easy production process. Under this premise, there must be room for the selection of mineral processing equipment and construction of the plant, which will provide conditions for future production development and process improvement.