In the paper, I make a detailed introduction to the hard rock gold mining from the rock gold geology, reserves, processing methods, to gold processing equipment. By reading this article, you are sure to have a generally clear and organized understanding of rock gold. Join us!

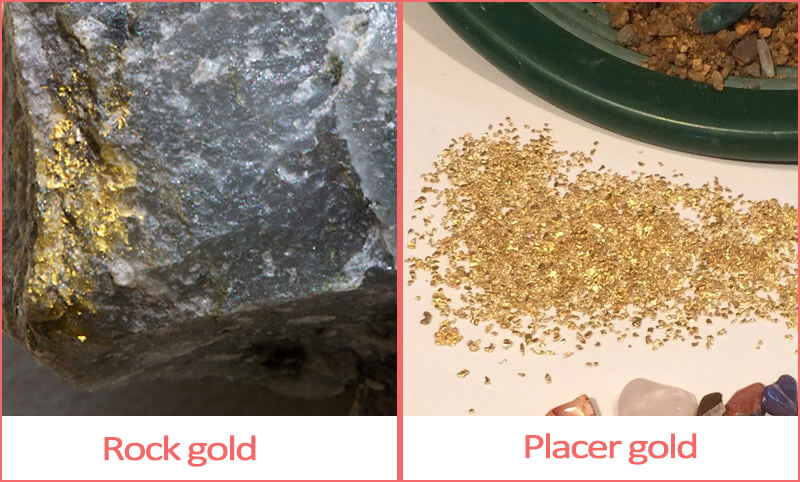

Hard rock gold is also called mineral gold which is produced in mines. Gold deposits, mostly deposited by hot springs gushing out of the ground through cracks in the rocks, are often sandwiched with quartz in cracks in the rocks. Most of the gold deposits are associated with other metals, including silver, platinum, zinc and other metals besides gold, which was called composite gold before other metals were put forward. Ore gold occurs in different mines and contains different components of other metals, so the fineness varies from 50% to 90%.

According to the structural state and gold content of gold in minerals, the minerals of gold deposits can be divided into three categories: gold ore, gold-bearing minerals and gold-carrying minerals. The so-called independent mineral of gold refers to the gold produced in the form of gold minerals and gold-bearing minerals. It is the most important form of occurrence of gold in nature and the main object of industrial development and utilization. So far, 98 kinds of gold minerals and gold-bearing minerals have been found in the world, but only 47 kinds are common, while only 10 kinds of minerals are directly used by industry.