The Chengmenshan Copper Mine is an open-pit copper under Jiangxi Copper Group. There are 2 mineral processing systems, all of which use heavy apron feeder transfer the ores to belt conveyor.

As the production capacity of the mine increases, the wear of the guard plate of the heavy plate feeder will increase, resulting in a shortened service life. The replacement of the guard plate is the main maintenance workload of the heavy duty apron feeder, downtime maintenance restricts the working efficiency.

Join us to know how to prolong the apron feeder service life.

Apron feeder model: 1200 mm×6048 mm

Chain width: 1200mm

Feeding speed: (0.064~0.1) m/s (frequency control)

Capacity: 200~350 t/h

Feed size: ≤300 mm

Material bulk density: 1960 kg / m3

Motor model: YP2-180M-4, 18.5 kW

Reducer model: M5RHT60, speed ratio: 436.87.

The two side guard plate of ore bin use wear-resistant steel, its service life for about 6 months.

Our engineer found that the part of the guard plate mounting bolt was worn seriously, and there was a risk of falling off guard plate, which caused a safety hazard to the next process.

According to the analysis, the guard is not evenly stressed, and the bottom wear is more series than the upper part.

Mainly due to the relative movement of the ore and the guard plate, the sliding friction and the pressing force are generated, thereby causing the wear of the guard plate.

In addition, as the ore falls from the heap to the bottom, the bottom ore moves faster and receives more pressing force. According to the principle of force and reaction, the bottom of the shield is crushed by ore. The force and friction are also greater, so the bottom of the guard plate wears more seriously.

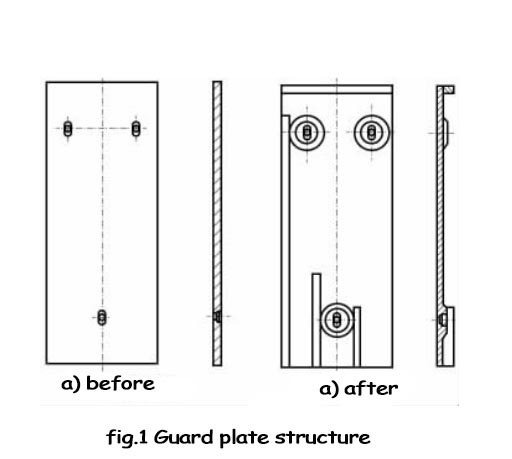

(1) Add the bolt protection device. A 20 mm thick round boss is designed at each bolt hole location to protect the bolts.

(2) Clever use of wear-resistant strip(Fig. 1). According to the wear trajectory of the material ore, add a wear-resistant strip on the panel (470 mm × 30 mm × 40 mm), and add 3 wear-resistant strips on the bottom (1075 mm × 30 mm × 40 mm, 400 mm ×30 mm × 40 mm, 250 mm × 30 mm × 40 mm).

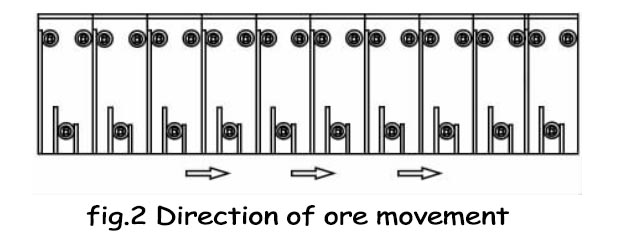

When the heavy plate feeder is running, the space formed between the wear strips will be filled with fine ore and small ore. These small ore and the guard plate are relatively static, forming a protective layer of the plate, reducing the wear caused by the direct friction between the guard plate and the large ore, thus extending the service life of the guard plate (Fig. 2)

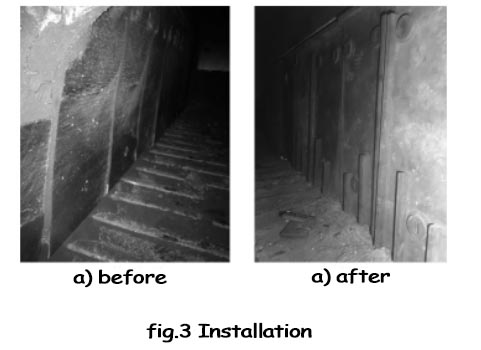

Through the structural optimization design of the guard plates on both sides of the mine ore bin, the problem of uneven wear and serious wear of the guard plate has been completely solved, and the service life of the optimized guard plate is extended from 6 months to 24 months (Figure 3).

The project has achieved good results, solved the problem of the short service life of the guard plate, reduced the frequency of maintenance and repair of the heavy apron feeder, reduced the labor pressure of the maintenance personnel, and improved the operating efficiency of the equipment and the stability of the production system.

JXSC, 35 Years of mining equipment manufacturing, provides types of ore feeders around the world (apron feeder, vibrating feeder, chute feeder, disk feeder, etc).

We are here help to help ⇒ mining machine selection, mineral processing solutions, processing plant optimization.