Silica sand, also known as quartz sand, is mainly composed of silica( SiO2), which is the main raw material for making glass. Silica sand has ordinary silica sand, refined silica sand and high purity silica sand. The content of silica in ordinary silica sand is between 90% and 99%, the content of iron oxide is less than 0.02%, the content of silica in refined silica sand is between 99% and 99.5%, the content of iron oxide is less than 0.015%, the content of silica in high purity quartz sand is 99.5% to 99.9%, and the iron oxide content is less than 0.001%. The silica sand with high purity is milky white. When the impurity content is more, the silica sand will be brown and light brown. The melting point of silicon sand is about 1750 C, the particle size is between 0.02mm and 3.35mm, and it is insoluble in acid except for hydrofluoric acid. It has good chemical stability, electric edge, wear resistance and so on.

What is silica sand?

Description

Silica sand distribution

Silica sand ore is rich in Algeria, India, Bangladesh, Brazil, Egypt, Singapore, Indonesia, Philippines, etc.

Silica sand classification

The regular specifications of silica sand are: 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80mesh, 100-120 mesh, 200 mesh, 325 mesh, SiO2 > 99-99.5% Fe2O3 less than 0.02-0.015%.

The silica sand raw material is usually will contain sticky clay, Kaolin clay, ilmenite, Hematite, Iron, and other magnetic minerals. The silica sand color in raw material maybe white, yellow, brown, etc.

Application

Silicon sand is an important industrial mineral raw material, widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, machinery, electronics, chemical, plastic, abrasive, rubber, aerospace and other industries. Another important use of silica sand is the filter and filter used for water treatment.

1) Glass: flat glass, float glass, glass products (glass jars, glass bottles, glass tubes, etc.), optical glass, glass fiber, glass instrument, conductive glass, glass cloth and special glass for anti ray

2) Ceramics and refractories: porcelain materials and glazes, high silica bricks, ordinary silica bricks and silicon carbide raw materials.

3) Metallurgy: raw materials or additives and fluxes of silicon metal, ferrosilicon alloy and silicon aluminum alloy.

4) Construction: concrete, cementitious material, road building material, artificial marble, cement physical property test material (namely cement standard sand)

5) Chemical: silicon compound and water glass and other raw materials, sulphuric acid tower filling, amorphous silica powder.

6) Machinery: the main raw materials for casting sand, abrasive materials (sandblasting, hard abrasive paper, sandpaper, abrasive cloth, etc.)

7) Electronics: high purity metal silicon, optical fiber for communication, etc.

8) Rubber and plastics: fillers (increase wear resistance)

9) Aeronautics and Astronautics: its internal molecular chain structure, crystal shape and lattice change law, with high-temperature resistance, low thermal expansion coefficient, corrosion resistance, high insulation, piezoelectric effect, resonance effect and its unique optical properties.

Silica sand processing methods

Generally speaking, the silica sand raw material is with sticky clay, kaolin clay, impurity minerals, magnetic minerals, such as ilmenite, hematite, iron, and others. So firstly need to wash clean the clay and kaolin clay, remove the waste sand and magnetic minerals, and finally sieve out requested size silica sand, dry it and packing it.

Silica sand process flow

In summary

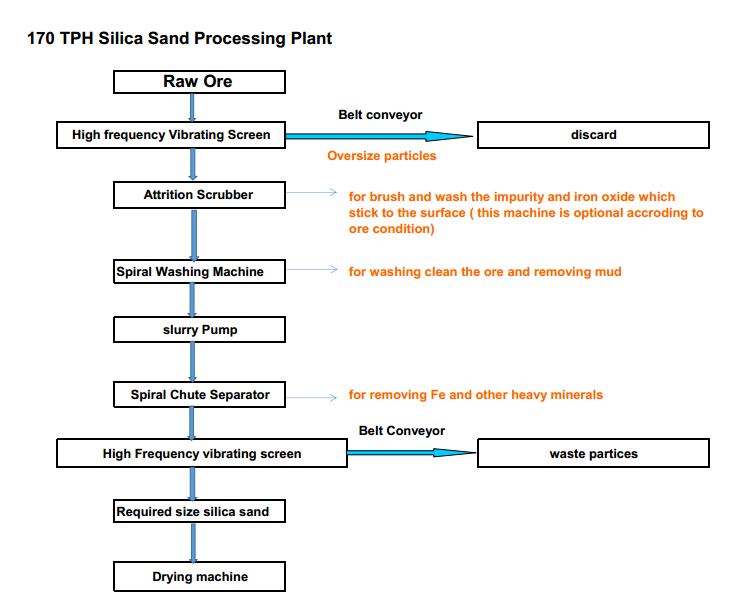

Feeding->washing -> primary sieving -> gravity separation to remove heavy minerals -> refining process to remove magnetic minerals -> Sieving out requested size silica sand -> drying -> packing

1. Silica sand Feeding

Use vibration feeding machine, feeding hopper, electromagnetic vibration feeder, belt feeder, wheel loader or excavator feed directly. It depends on process capacity and raw material conditions to choose which feeding machine.

2. Clean clay

Washing clean the clay, kaolin clay and mud in raw material, most popular silica sand washing machine are trommel scrubber, log washer, spiral washer, attrition scrubber, etc. Wash machine for sale

The silica sand washing attrition scrubber and spiral classifier washing machine are especially good washing effect for small size silica sand -3 mm. If bigger size, can consider using trommel scrubber and log washer to wash silica sand.

3. Primary Sieving to remove coarse waste sand

After washing clean the clay, then need to sieve out some bigger waste sand, the under-screen sand will go to next gravity separation machine. This sieving process can use normal vibration screen or silica sand high-frequency vibration screen. Vibrating screen details

4. Gravity separation to remove heavy minerals

It is for primary silica sand gravity separation to remove heavy minerals, such as ilmenite, hematite, iron, etc, the most common use silica sand separation machine is shaking table, spiral chute separator. It depends on the processing capacity to choose which gravity separation machine.

If a big capacity plant, usually uses spiral chute separator with bigger capacity. If a small capacity plant, usually uses shaking table to separate out silica sand.

6. Silica sand refining process removes magnetic minerals

After silica sand gravity separation, there will still some percentage magnetic minerals in silica sand, so need to remove it by magnetic separator, different magnetic minerals, will use different gauss magnetic separator, for removing iron, need 1000 gauss, for removing ilmenite and hematite, need 8000-9000 gauss. Different usage of silica sand, will request different percentages of magnetic minerals remaining in the final silica sand product.

7. Sieving out requested size silica sand

After removing magnetic minerals, will need to sieve out requested size silica sand, usually use the high frequency vibration screen, with PU screen, screen mesh size can be customized.

8. Drying

After sieving out final silica sand, then drying the sand by drying mahcine.

9. Packing

After drying the sand, use packing machine to pack final silica sand product ,then can sale. The silica sand packing machine is ton bag packing machine, can be 0.5 T, 1 T, 2 T, or 3 T per bag as requested.

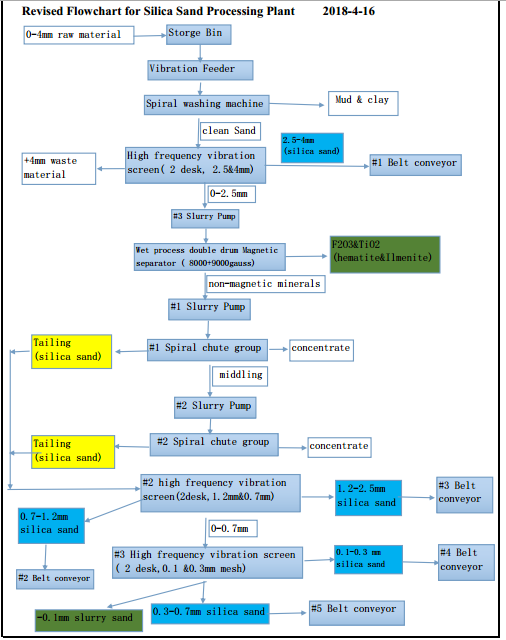

Silica sand plant flowchart

Silica sand processing equipment manufacturer

JXSC mine machinery factory in China has more than 30 years of professional experience at silica sand processing plant, design full set silica sand process flowchart, provide complete set silica sand washing plant, can send the engineer to the mine site for equipment installation and commissioning guidance. We have already built many silica sand separation plants in Algeria, India, Bangladesh, Brazil, Egypt, Singapore, Indonesia, Philippines, etc.

—Silica Processing Plant—

50TPH Silica Sand Processing Plant in Indonesia

65TPH Silica Sand Washing Plant in Malaysia

100TPH Silica Sand Processing & Washing Plant in Malaysia

20TPH Beach Sand Mining Plant in India

100TPH Beach Sand Zircon Mining Plant in Sierra Leone

LATEST PRODUCTS

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…

Slurry Magnetic Separator

【Capacity】10-100 m3/h 【Feeding Material Densi…

Vertical Ring High Gradient Magnetic Separator

【Capacity】0.01-150 TPH【Feeding Size】0-1.2…