Application of Nelson Concentrator in Gold and Precious Metal Concentrating Plant

Knelson concentrator cooperates with a gold shaker is a kind of advanced gravity beneficiation model with high efficiency and good environmental protection performance. The theory and examples of using a Nelson concentrator to recover gold and other precious metal with a gravity separation process are discussed in order to reduce the use of sodium cyanide and other chemical agents in gold mines.

What’s the best substitute for Knelson Concentrator?

1 Introduction of Knelson concentrator

The key problem to be solved by sorting fine particles is how to increase the sedimentation speed difference.

For fine particles, due to the decrease of sedimentation velocity, the velocity difference in light and heavy ore particle is reduced. The classification of fine-grain carried out in the gravitational field is either very low efficiency or fail. On the contrary, the classification effect is enhanced in the centrifuge field.

2 Structure and working principle of Nelson concentrator

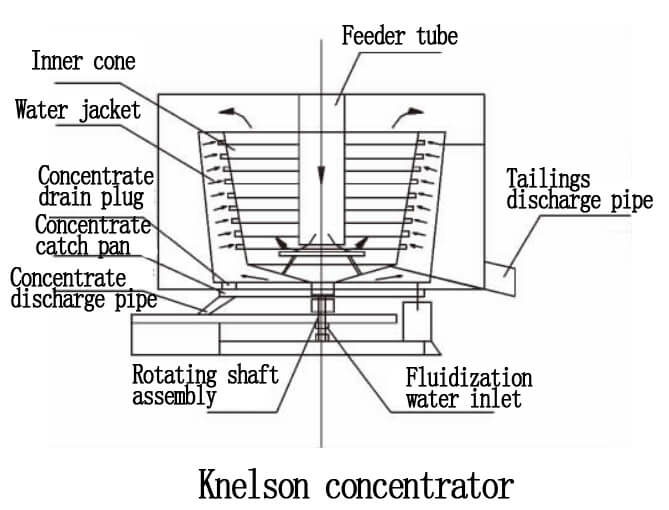

2.1 Structure

The separation part of the Nelson gold concentrator is a double-wall cone with flushing holes on the inner wall, and a sealed water chamber is formed between the outer cone and the inner cone. On the inner wall of the inner cone( also called as concentration cone) has several circles of groove, and water inlet holes.

2.2 Working principle

Knelson concentrator is a gravity concentrator based on centrifugation. In the high-intensity gravity field, the gravity difference between the mineral of high density and of low density will be amplified greatly, this gravity difference makes separating task in the high-intensity gravity field is easier than that of the normal gravity field. Under the interaction of fluidized water and hindered settlement, the mineral layer can keep losing condition continuously. Then the heavy mineral particles are settled, and the light minerals are discharged as tailings.

When the machine at work, the ore pulp feeds into the bottom of the enrichment cone, the pulp is thrown to the inner wall because of the centrifugal force and moves up along the inner wall. At the same time, the water enters the chamber by through the inlet holes continuously, and make the mineral layer keep the state of flow.

Under the interaction of centrifugal force and bounce-back force of water, the heavy mineral can bear the radial resistance, centrifugal settle in the concentrated layer. However, the gangue mineral cannot bear the bounce back force of water, discharge at the final.

3 Case of Nelson concentrate application

3.1 Description of the gold mine

A mining area in Africa has a rich gold reserve, the primary ore is sulfide gold ore, the oxidized ore is quartz vein type. Main metal minerals are iron pyrite, limonite, native gold, and few amounts of galena and sphalerite. The gangue minerals are mainly quartz, sericite, and pelite. The useful components are single and mainly natural gold, the content of harmful component is low, and the gold grade of original ore is AU 5. 3G / T.

Crushing: three stages and one closed circuit

Grinding: one closed circuit( -200 mesh takes 60%)

Classification: FX-350 hydroclone(2 sets)

Gravity separation: KC-CD20MS Knelson gold concentrator(2 sets) + 6S shaker(1 set)

Tailings management: flotation

Recovery rate: 94%

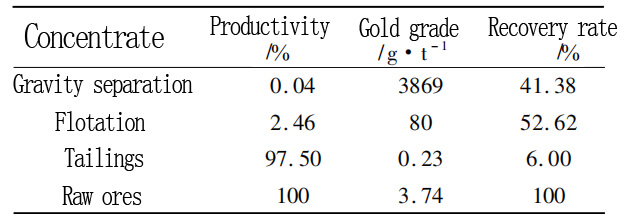

3.2 Mineral index

3.3 Gravity separation process

Knelson concentrator is an efficient centrifugal gravity separation equipment, suits for recovering precious metals such as gold, silver, platinum group and other heavy metal minerals, and has become one of the most used gravity separation machines.

Advantages of Nelson concentrator:

- High beneficiation ratio.

- High grade of gold concentrate, the recovery rate of coarse gold( up to 41.38%) is greatly higher than that of the method of the gold sluice.

- Automatic operation, stable, wear-resistant.

- No harmful chemicals such as mercury or sodium cyanide.

JXSC is a Chinese mining equipment provider, email us know the Knelson concentrator price quickly.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…