Laboratory crushing mill is a common sample crushing equipment in the laboratory. Now many tests require full crushing and grinding of samples.In a lab setting, most materials used for sampling are non-homogeneous mixtures. The best method of obtaining a small sample of these mixtures is to take a quantity of the material big enough to be compositionally representative, and then reduce it to a fine powder. This is where laboratory crusher, ball mill & grinding, sample pulverizer come in. All of them are essential for crushing, milling/grinding, pulverizing, and chopping samples for routine analysis. Usually the performance of the equipment will greatly affect the crushing effect. Under normal circumstances, the quality of the instrument can be seen from its crushing degree.

Why Grinding or Milling in Laboratory Setting?

The main purpose of grinding samples is to ensure that each analytical aliquot represents the initial sample. Only by fully understanding the methodology and paying close attention to the details can this goal be achieved. Generally, all analytical samples should be ground. Analyzing a sample that has not first been ground can produce misleading results, as the particular sample chosen may not be compositionally representative of the entire sample.So grinding or milling is essential to ensure that a sample is fully homogeneous before it is analyzed.It is for these reasons that many laboratories use some form of lab mill or grinder. However, for some samples a judgment must be made on the benefit gained from grinding. Generally, all samples must be dried or have been dried to a suitable range.

The Process of Lab Crushing & Grinding

1. Sample Weighing

Using the customer’s barcodes to register the sample in the laboratory’s registration system. Weighing of samples and input the dates to the electronic database of the laboratory.

2. Drying the Sample

Take the samples into electric drying cabinets to make them dry. The controlled temperature of the electric drying cabinets should be at 80 – 105 ° C for 10-12 hours. Also you need to record the drying temperature of each batch of samples in a logbook or in the electronic database of the laboratory.

3. Crushing Samples

First crushing the sample to 2 mmwith a jaw crusher. Crushing control is carried out by sifting each 20th sample through the appropriate sieves. Make sure the material pass through the sieve above 70%.

4. Quartering of Samples is Carried Out Using Boyd’s Rotary Dividers

Accordingthe results of quartering (reduction), a working sample is allocated for subsequent abrasion, the weight of which depends on the final dimension of the crushed sample, the distribution coefficient of the useful component in the ore (the approximate weight of the sample is 1000 g). The weighed portion (“tails”) remaining after quartering is poured into the same bag in which the sample was delivered to the laboratory. The sample field label is also placed in this bag. In the future, the tailings of crushed samples in the amount of 2.5% will be used to control the quality of quartering.

5. Evaluate Abrasion of Samples

The abrasion of samples consists in grinding the working portion of the crushed sample to a fraction of 0.075 mm.The quality of abrasion is assessed by sifting the powder of each 10th sample through a sieve with a mesh size of 0.075 mm, which corresponds to 200 mesh. If 85% of the sample passes through the sieve, the abrasion is considered satisfactory.

6. Separation by Hinges

The rubbed sample is divided into a laboratory sample and three duplicates, 50 g each. The worn out duplicates of the sample and the remains of the worn out powder sample are subject to return to the Customer. From the analytical sample by the Contractor, according to orders for analytical work, weighed portions are taken for various types of analyzes. All formed weighed portions of samples after sample preparation should be packed in bags made of kraft paper. The bags should be closed with an elastic wire. All packages must be signed with the order number, sample number and sample weight. A label is placed inside the package, which indicates the sample number, order number, and the name of the customer’s organization. Packages for each type of analysis should be packed in cardboard boxes measuring 19x21x40 cm. Each box should be labeled with the name of the organization, the name of the deposit, the order number, the weight of the samples, the numbers of the samples contained in this box.

7. Clean the Equipment

It is important to keep the working surfaces clean to prevent possible contamination of the subsequent sample by the remnants of the processed sample when carrying out sample preparation. In this regard, make sure that the working surfaces of crushers and mills are cleaned after each sample with compressed air and vacuum (vacuum cleaner). After crushing and abrasion of each sample represented by clay or clay-gravelly material (from the weathering crust), it is necessary to clean the cheeks and bowls with an inert material. To control the quality of sample preparation, the customer will use blank samples.

Laboratory Crushing & Grinding Equipments for Sale

Lab Crushers

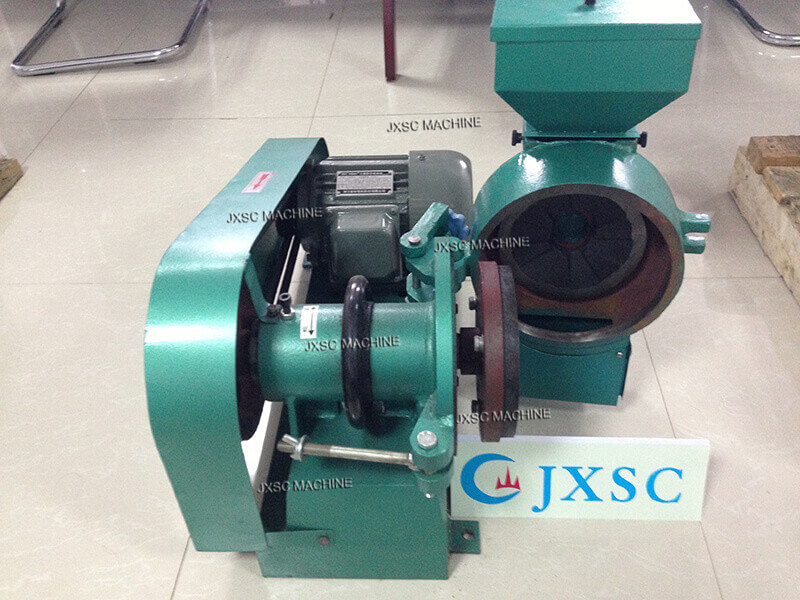

Laboratory Disk Mill — It mainly used for medium hardness ore crushing, laboratory disk mill is metallurgical, geological, building materials, chemical industry laboratories or laboratories, materials crushing equipment.

Small Jaw Crusher, Hammer Crusher, Roll Crusher — They are mainly used for laboratory, crush ore, coal, gangue, coke, asphalt, mine, cement, metallurgy, building materials, roads, etc.,

Lab Ball Mill & Grinding

Ball Mills — They are capable of grinding materials very fine. A wide selection of grinding media is available for efficient reduction of various material types. Optional accessories can be selected to enhance wear-resistance, reduce contamination, and optimize operation. QM cylinder ball mill, XMQ cone ball mill and XMB laboratory rod mill are popular.

Lab Screening & Sieving

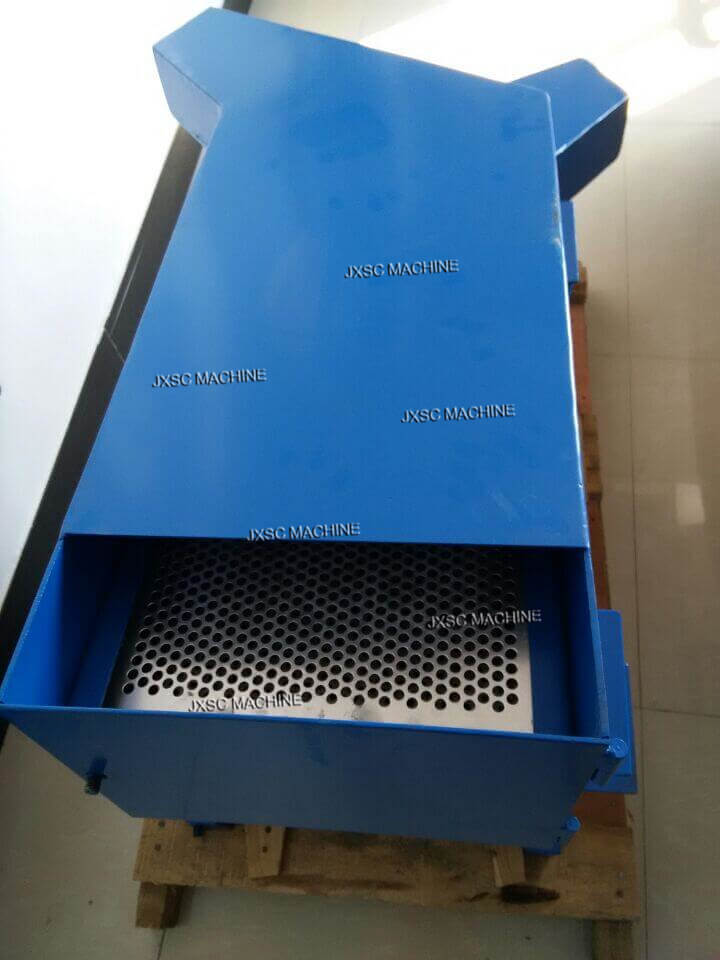

Laboratory Vibration Screen — Small Vibration Screen is used to screen the material particles. Its capacity is 0.1-3 TPH and feeding size is 0-45 mm. It is widely used to sieve materials in scientific research institutions or factory laboratories for metallurgy, geology, fuel and chemical, building engineering field.

Sieve Shaker — The feeding size is 0-5mm. This Sieve Shaker is widely applied in laboratories for light, heavy Geological, metallurgical, chemical, building material, coal, mine, grinding wheel ceramic and pharmaceutical industries and research institutes, laboratory vibrating sieve is an ideal vibrating sieving machine for industrial sieves and screens of materials in the mining industry.

There are also another mining equipments for laboratory used, such as planetary mills, cutting and knife mills, mortars, disc mills, rotors, and beater units, cryogenic models, and so on. JXSC Machine has more than 35 years experience on mining machines manufacture, if you just need such products, welcome to contact us for a free quote.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…