As a professional jig separator manufacturer, we design and know the separator well. We will tell you the main factors affecting jig concentrator. It includes structural factors, operation factors and the nature of raw ore.

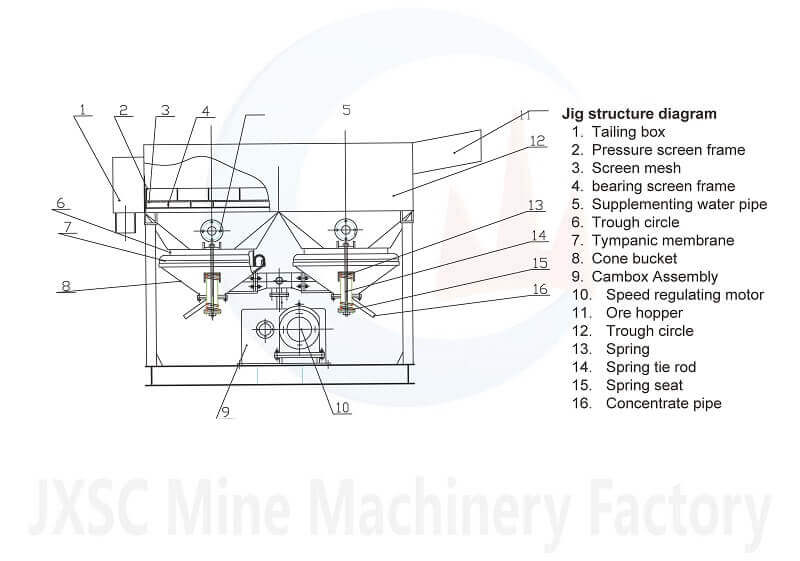

Structure of Jig Separator

The structure of jig separator has a great influence on the separation index, so it should be considered in the design and manufacture.

- The screen area of jigging chamber is an important factor affecting the productivity. Increasing the screen area can increase the productivity;

- The size of the sieve should be determined according to the size of the feed and the way of discharging the heavy products;

- The number of jigs depends on the nature of the material, the quantity of ore and the requirements of product quality;

- The stroke coefficient (the ratio of diaphragm area to screen area) determines the uniformity of water flow distribution. The larger the stroke coefficient is, the more uniform the water flow distribution is;

- The height difference between the front and rear sieve plates, that is, the size of the drop, has a direct impact on the speed of material flow. When the material selectivity is good, the drop can be larger. When the material is difficult to select and the product quality requirements are high, the drop should be smaller.

Operational Factors

1. Stroke and Frequency

This is one of the important factors affecting the selection index. Because the stroke and frequency determine the velocity and acceleration of water flow, it directly affects the loose and layered state of bed and the effect of water flow on ore particles, thus affecting the separation effect. Generally, for the case of coarse particle size, high density, large treatment capacity and small amount of water added under the screen, larger stroke and smaller stroke can be used; When the particle size is small and the bed is thin, a smaller stroke and a larger number of strokes should be used.

2.Make Up Water Under Screen

Sieve water can increase the bed looseness and reduce the intensity of suction. When selecting wide grade materials, the amount of water under the screen should be smaller, which can reduce the rising water flow speed and prevent the dense fine materials from being washed into the overflow. When selecting narrow grade coarse-grained materials, the amount of water under the screen can be appropriately increased to make the bed loose.

3.Bed Thickness

The bed can be divided into upper, middle and lower layers. The upper layer is light mineral flow moving layer, the lower layer is heavy mineral subsidence layer, and the middle is intergrowth or transition layer. Generally speaking, when the density difference between heavy minerals and light minerals is large, in order to speed up the stratification speed and improve the treatment capacity, the bed can be thinner; When the quality of concentrate is high, the bed should be thicker, because the bed is thick, the particles are difficult to pass through, the stratification time is long, and the quality of heavy products is high. When dealing with fine materials and discharging ore under the screen, it is necessary to lay an artificial bed on the screen.

4.Feed Concentration

Feed concentration is one of the factors that determine the horizontal flow velocity of the selected material in jigging process. The suitable feeding concentration is generally 20% ~ 40%.

5.Treatment Capacity

Generally speaking, the treatment capacity should be increased as much as possible on the premise of ensuring concentrate grade and recovery rate. But when the treatment capacity exceeds a certain range, it will increase the loss of useful minerals in tailings. When the concentrate grade is high, the treatment capacity should be reduced accordingly.

Influence of Ore Properties

The density composition and particle size composition are important for jigging.

The density composition of ore determines the wash-ability of materials. The greater the density difference between light and heavy minerals, the higher the separation efficiency.

The particle size composition of ore feed determines the properties of the bed, the resistance of water passing through the bed and the size of voids between particles. It has a great influence on the loosening and stratification of the bed.

The above is the summary of the main factors affecting the jig separator. The jigging is generally used before screening classification.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…