Gold mining is an energy intensive and greenhouse gas (GHG) emission intensive industry. With the identification of climate change risk as financial risk and the adoption of the Paris Agreement in 2015, enterprises’ greenhouse gas emissions and emission mitigation actions have been more strictly reviewed to improve environmental sustainability.

What is the scope of greenhouse gas emissions from gold mining?

Scope 1 – Direct emissions from the production of projects owned or controlled by the company (e.g. emissions from on-site power generation, mining, processing and smelting of gold bars).

Scope 2 – Indirect emissions from the purchase of energy consumption in the operation of projects owned or controlled by the company (for example, the purchase of power grids for coal-fired or natural gas power generation).

Scope 3 – Indirect emissions from broader economic activities due to the company’s activities come from sources not owned or controlled by the company (e.g. emissions from the production of purchased materials and fuels, the transportation of goods to the site, taking commercial aircraft, and the refining and subsequent use of gold).

Greenhouse gas emissions are reported as carbon dioxide equivalent (CO2-e), including the following greenhouse gases: carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), sulfur hexafluoride (SF6), hydrofluorocarbons (HFC) and perfluorocarbons (PFC).

Most large and medium-sized gold mining companies reported total emissions in their company scope 1 and 2, and most companies also provided details of their mining operations. At present, few companies report emissions in scope 3. Gold mining is different from bulk commodities such as iron ore or coal because most scope 3 emissions occur upstream of the mine, i.e. from suppliers providing goods and services to the mine.

The scope3 emissions of coal and iron ore are mostly downstream, from combustion to steel production.

There are two common emission intensities for gold mining

1. Greenhouse gas emissions per ton of ore processed;

2. Greenhouse gas emissions per ounce of gold produced.

The emission intensity of producing gold per ounce is most suitable for comparing companies or mines in the form of greenhouse gas emission intensity curves. The main drivers of gold emissions per ounce are mine energy, mine type (open-pit or underground), gold grade of ore and mine depth.

The emission intensity per ton of ore processed helps to evaluate the absolute change of greenhouse gas emissions from steady-state production mines. However, unless the mines have the same production and processing capacity, the comparison between mines is useless.

Relationship between greenhouse gas emissions and physical gold mining parameters

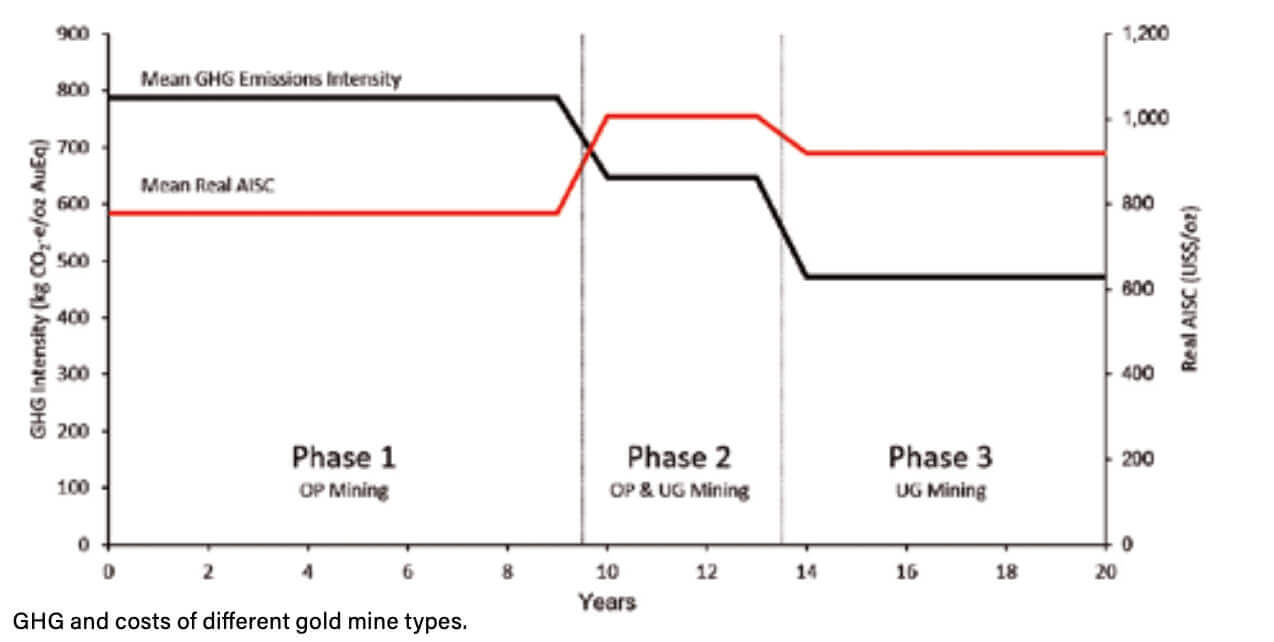

A recent study investigated the relationship between greenhouse gas emissions, gold grade, energy, mine type and production cost (AISC – total maintenance cost) of gold mines in Australia (Ulrich et al. 2020).

There is a close relationship between the gold grade of processed ore and the greenhouse gas emission intensity per ounce of gold produced. The higher the gold grade, the lower the greenhouse gas emission intensity (and vice versa), and the lower the AISC.

The data are also analyzed according to the mine type. On average, the greenhouse gas emission intensity of open-pit mine is the highest and AISC is the lowest. Mines that purchase ore from open-pit and underground mines have the highest cost, but their greenhouse gas emission intensity is low.

The emission of gas from underground mines is lower than that from open-pit mines, but the intensity of gas from underground mines is lower than that from open-pit mines.

The average emission intensity of underground mines in Australia is 40% lower than that of open-pit mines. Further research shows that underground and open-pit mines in other countries have the same systematic differences in greenhouse gas emission intensity and production cost.

One challenge in the gold industry is the decline in gold grade. In Australia, gold grade decreased by 25% from 2.44 g / T in 2006 to 1.83 g / T in 2017.

It is expected that the gold grade will further decrease by 44% to 1.02 g / T by 2029. A 44% reduction in gold grade means an increase in greenhouse gas emission intensity of 32-50%, depending on whether the mine is open-pit or underground or a combination of both.

Energy Competitive Advantage

In terms of energy, some gold producing countries have obvious competitive advantages over other gold producing countries. For example, most of Canada’s gold mines are located in mainly low emission provinces, where energy comes from hydropower and nuclear power.

Australia’s gold mining depends on fossil fuel energy. In Australia, gold mines are either connected to a power grid that is mainly powered by coal and natural gas or to remote mines that generate electricity on site with diesel and natural gas.

From this perspective, the weighted average greenhouse gas emission intensity of the gold mining industry in Canada is 244 kg carbon dioxide equivalent (CO2-e) / oz, while that in Australia is 637 kg carbon dioxide equivalent (CO2-e) / oz.

The gold industry in South Africa has the largest emissions, with a weighted average greenhouse gas emission intensity of 2754 kg carbon dioxide equivalent (CO2-e) / ounce, and its energy comes from inferior coal. In addition, many South African mines are more than 2km deep and require considerable energy to ventilate and cool them.

Gold miners began to address social concerns about climate change and investors’ concerns about financial risks by increasing the disclosure of climate risks and carbon emissions, and carried out activities to reduce greenhouse gas emissions.

Current emission reduction measures include energy substitution or improving energy efficiency. Energy substitution either uses fossil fuels with low carbon emissions, such as replacing diesel with natural gas; Or replace fossil fuels with renewable energy sources (such as solar and wind energy).

The mines that have recently implemented energy substitution in Australia include Agnew, Tanami and Granny Smith mines.

Improving energy efficiency includes strategies to minimize fuel use or install ventilation on demand in underground mines. The introduction of electric vehicles and mining fleets in underground mines has reduced the use of fossil fuels and the energy required for ventilation.

Since the electrified mining fleet is in the early technical stage, only a few mines in Canada have introduced this technology.

We can expect to see more mines adopt this form of technology to cope with climate change and successfully reduce greenhouse gas emissions in the next few years.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…