The preparatory work for operating a quarry is divided into the early stage and the later stage, the early stage is mainly to apply for sand mining qualification. This article mainly introduces the later stage work, that is, buying quarry equipment. Answer your questions like ‘What is quarry machine‘, ‘quarry equipment cost‘.

What is quarrying

Quarrying is mainly to provide qualified construction aggregates for high-grade highways, high-speed railways, roads, and bridges. In addition to natural stone, quarrying equipment can also be used to produce artificial sand, such as mine tailings sand, urban construction waste sand, and other machine-made sand industries.

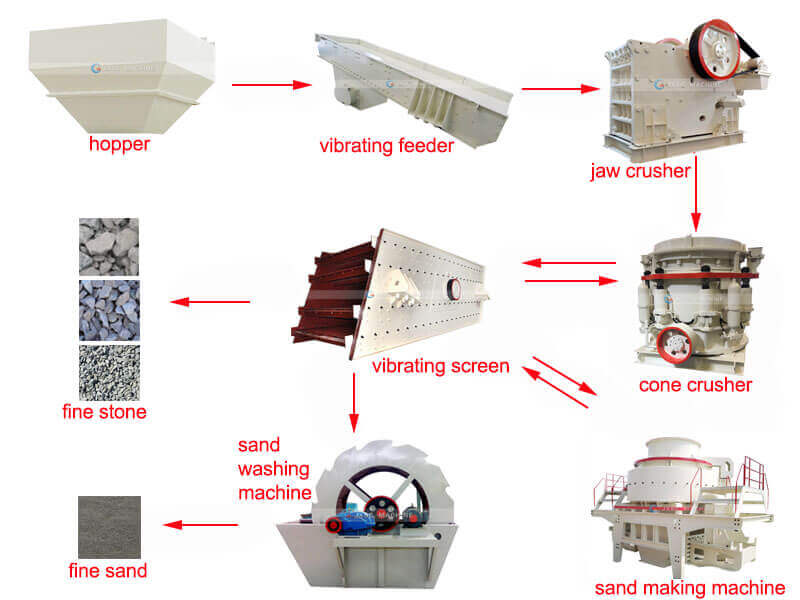

What is the rock quarry equipment

The quarry equipment mainly includes feeding, crushing, screening, sand making, conveying and material transportation equipment. Among them, the crushers are the most critical and expensive equipment in the entire rock quarrying system.

Generally speaking, the quarry used rock crushers are divided into coarse crushing, medium-fine crushing and sand making machine. PE jaw crusher, single-cylinder cone crusher, and sand making machine correspond to coarse crushing, medium-fine crushing, and sand-making respectively. They are high-yield, cost-effective, and are your good choice.

Vibrating feeder

The feeder can transport stones and rocks to the crushing equipment in a timely, regular and continuous manner, with high efficiency and energy saving, small footprint, convenient adjustment and long service life.

Jaw crusher

PE jaw crusher is used in the first process of various rock crushing, can crush rock with compressive strength not higher than 320MP and a maximum feed particle size of 125mm ~ 1020mm to medium particle size. It has a good crushing effect on quarries based on raw materials such as limestone, cobblestone, granite, basalt, calcium carbide, and coal gangue. Large jaw crushers are favored by quarry investors due to their large processing capacity and strong market competitiveness.

Cone crusher

Cone crusher is mainly used for medium-fine crushing, such as iron ore, non-ferrous metal ore, granite, limestone, quartzite, sandstone, river pebble, etc. For hard stones such as cobblestone, granite, coal gangue, if adopt the crushing process of “jaw crusher + sand maker”, it may cause serious wear of the sand maker. In order to relieve the pressure of the sand making machine, a cone crusher is added in the middle.

From the process point of view, adding equipment is equivalent to increasing investment costs, but for long-term investment in quarry mining work, reducing the wear on fine sand making equipment, increasing the service life, creating more profits.

Single-cylinder hydraulic cone crusher combines mechanical, hydraulic, electrical, automation, intelligent control and other technologies into one. It has the advantages of high crushing efficiency, convenient maintenance and adjustment, and excellent particle shape of the crushed product, widely used in metal, non-metallic ore, cement, sand and stone, metallurgy and other industries.Sand making machine

Sand making machine, or called vertical shaft impact crusher (VSI), crushes 30-50mm stone to 0-5mm by impact energy. The vertical shaft impact crusher adopts a new four-port impeller design structure and is equipped with a special seal structure to prevent oil leakage from the bearing cylinder. VSI crusher is efficient sand making equipment, can crush all kinds of ultra-hard, medium-hard and corrosive materials, provides high-quality aggregates for expressways, high-speed railways, high-rise buildings, municipal administration, hydropower dam construction, and concrete mixing stations.

Quarry equipment price

Frankly, there is no an exact price of how much will a rock quarry plant requires, price is varied in material, capacity, final product quality. Before starting a quarrying business, it is necessary to make a comprehensive assessment of stone prices, market demand, equipment prices, policies, site conditions, and rock quarrying process technology.

Regarding the quarrying equipment price, quarrying process and other any problems, pls kindly contact us, there will be professionals to provide you with configuration plans and quotes.

Rock quarrying process

1000 TPH limestone crushing production line

Processed material: limestone

Processing technology: dry crushing, sand processing

Capacity: 1,000 tons per hour

Output granularity: 0-5-10-20-31.5mm

Daily running time: 10-12 hours

Finished product: meet the construction sand standard

Uses: highway, railway, construction, municipal and other construction areas across the country

Equipment configuration: jaw crusher, impact crusher, circular vibrating screen, vibrating feeder, belt conveyor, etc.

500 TPH basalt crushing line

Processed material: basalt

Processing technology: dry crushing, sand processing

Capacity: 500-650 tons per hour

Input granularity: less than 1020mm

Output granularity: 10-30mm, 5-10mm, <5mm

Daily running time: 20 hours

Finished product: meet the construction sand standard

Uses: highway, railway, construction, municipal and other construction areas across the country

Equipment configuration: PE900X1200 jaw crusher, cone crusher 2 sets, vibrating screen, vibrating feeder, belt conveyor, etc.

400 TPH granite sand making line

Processed material: granite

Processing technology: dry crushing, sand processing

Capacity: 400-550 tons per hour

Output granularity: 0-4mm, 4-11mm, 11-23mm

Daily running time: 15 hours

Finished product: high quality fine sand

Equipment configuration: PE900X1200 jaw crusher, sand making machine 1 set, cone crusher 2 sets, vibrating feeder, belt conveyor, etc.

LATEST PRODUCTS

Belt Feeder

【Capacity】 10-450 t/h 【Power】 1.5-2.5 kW/Mete…

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …