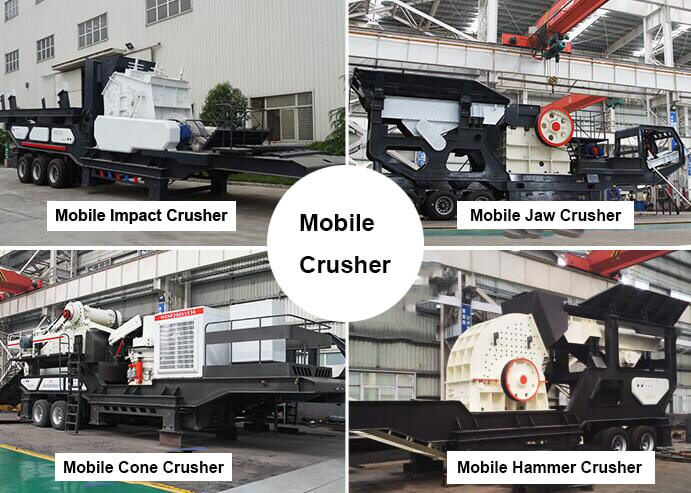

The small mobile crusher is well received by users due to its small footprint, convenient and flexible movement, and “walking production line”.

Small mobile crushers are mainly divided into tire-type mobile crushing stations and crawler-type mobile crushing stations according to the walking mode. According to the user’s production requirements, diversified unit configurations can be carried out. The main matching hosts are: jaw crusher, Impact Crusher, cone crusher, heavy hammer crusher and impact sand making machine.

Small Mobile Jaw Crusher

Feed Size: ≤800mm

Capacity: 85-650t/h

Advantages:

- First-level coarse crushing, large feed inlet, strong crushing force

- Less space, simple structure, easy to operate

- Inside contains iron remover to remove unbreakable materials, and the remaining materials are transported to the lower-level crushing equipment.

Innovative Heavy-duty Jaw Crusher for Sale

Our engineers have more than 30 years of experience in field investigation and study in mines and quarries. We understand your needs and your expectations for crushing equipment. Therefore, our heavy-duty crusher provides a variety of models and specifications for you to choose from. No matter which model you choose, you can get unique advantages: improve production efficiency, reduce costs and maximize return on investment.

Our mobile jaw crushers have a wealth of innovative features. Compact design and high mobility. The output can be maximized through hydraulic adjustment of the discharge port setting. The engine is powerful and fuel-efficient. Dust-proof components are durable and have a long service life. In order to achieve the ultimate production efficiency and operation convenience, comfort and safety, we have integrated a series of technical features, including automation systems and various maintenance platforms. The former not only provides comprehensive control over the process flow, but also eliminates the risk of injury during operation; the latter provides a safe working environment.

Our Mobile Jaw Crusher — Specially Designed for Your Application

Mobile jaw crushers must meet your unique application requirements. Whether it is to use reverse crushing to handle viscous materials and release blockages, or require a variety of feed port sizes and output ranges to meet your different crushing ratio needs, or any other special requirements, our mobile jaw crusher Can be perfectly adapted to your application, provide the best output while reducing operating costs, and maximize the return on investment of the crusher.

Small Mobile Impact Crusher

Feed Size: ≤800mm

Capacity: 30-650t/h

Advantage:

- The coarsely crushed materials are fed into the machine through the conveyor for secondary medium and fine crushing (suitable for soft materials), with shaping function, good particle shape, and less dust.

- Inside the vortex cavity The air flow is self-circulating, the double dust filtering system, and environmental protection measures are in place.

Flexible Control Mobile Impact Crusher for Sale

In order to maximize productivity and efficiency, our mobile impact crushers have the functions of optimizing throughput and preventing overload. They use a direct drive system to achieve the best fuel efficiency and reduce operating costs; in addition, these devices also contain many user-friendly features to ensure easy operation and easy maintenance.

Our impact crusher can be equipped with a suspended screening machine to produce products with precise dimensions and ready-to-use to maximize production efficiency and profitability.

Small Mobile Cone Crusher

Feeding Size: ≤560mm

Capacity: 80-650t/h

Advantages:

- It can process high-hardness materials and has a large output, but the requirements for discharging are not high, and the grain shape is not good.

- The hydraulic system can control the feeding and discharging of the equipment, the folding of the conveyor belt and other actions, and the PLC intelligent operating system , Stable operation, rest assured, convenient operation;

- Slightly more expensive, but the use cycle is long.

Our Mobile Cone Crusher — Produce More High Value-added Granular Grades

Our mobile cone crusher series provide you with high-quality products and excellent grain shapes obtained after secondary/tertiary crushing. After rigorous testing and testing, the solution can meet various crushing ratio requirements and provide the necessary flexibility to ensure that each model in the series can crush almost any material specified by the application.

Our hydraulically regulated hydrocone crusher is rugged, easy to maintain, does not require too much operator intervention, is not only versatile, but also easy to maintain. With a wealth of crushing cavity options and eccentricity adjustment, this makes it one of the most versatile and reliable cone crusher series on the market today.

Mobile Cone Crusher for Sale — With Flexibility as Its Design Purpose

We understand your application and understand that your needs change rapidly. Therefore, when designing a mobile cone crusher, we want to provide you with maximum flexibility. Provides functions such as an automatic setting adjustment system, remote camera and level indicator, allowing you to monitor and optimize production in real time; the additional advantage of tracking lining wear will help minimize production interruptions and downtime.

Our mobile cone crusher has a high crushing ratio and can minimize the associated fine material. It is an ideal solution for secondary and tertiary crushing. Our market-leading “S” cone crushers can accept feed sizes that are 90% larger than current standard cone crushers; they can even operate as primary crushers in gravel applications. It has high mobility and short set-up time to help you start your project on time every time.

Small Mobile Heavy Hammer Crusher

Feed Size: ≤1000mm

Capacity: 100-3000t/h

Advantage:

- It can be formed at one time without the need for a secondary crushing and shaping process. It is only suitable for crushing limestone and medium-hardness stones with a compressive strength of less than 200MPa.

- Large inlet, good shape of the finished product , The production process is sealed and environmentally friendly, spraying and dustproof, and the production efficiency is improved by 60%.

As one of the world’s leading manufacturers of mobile crushers, we understand that you need equipment that can coordinate operations in order to provide the best finished products. We have devoted ourselves to this field for several years, and we are very clear about the challenges you face in crushing applications. To help you solve these problems, we continue to develop and improve products.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…