Ilmenite is a mineral composed of titanium iron oxide, with the chemical formula FeTiO3. It is one of the most important titanium ores, a metal known for its high strength, corrosion resistance, and low density. Ilmenite typically appears as black or dark brown crystals or grains in igneous rocks and sedimentary deposits. Ilmenite’s significance lies in its role as a primary source of titanium, a valuable metal in the modern industrial world. The demand for titanium continues to grow due to its unique combination of properties, which make it a critical material in various high-tech and industrial applications.

Common Ilmenite Beneficiation Methods

1. Ilmenite Gravity Separation

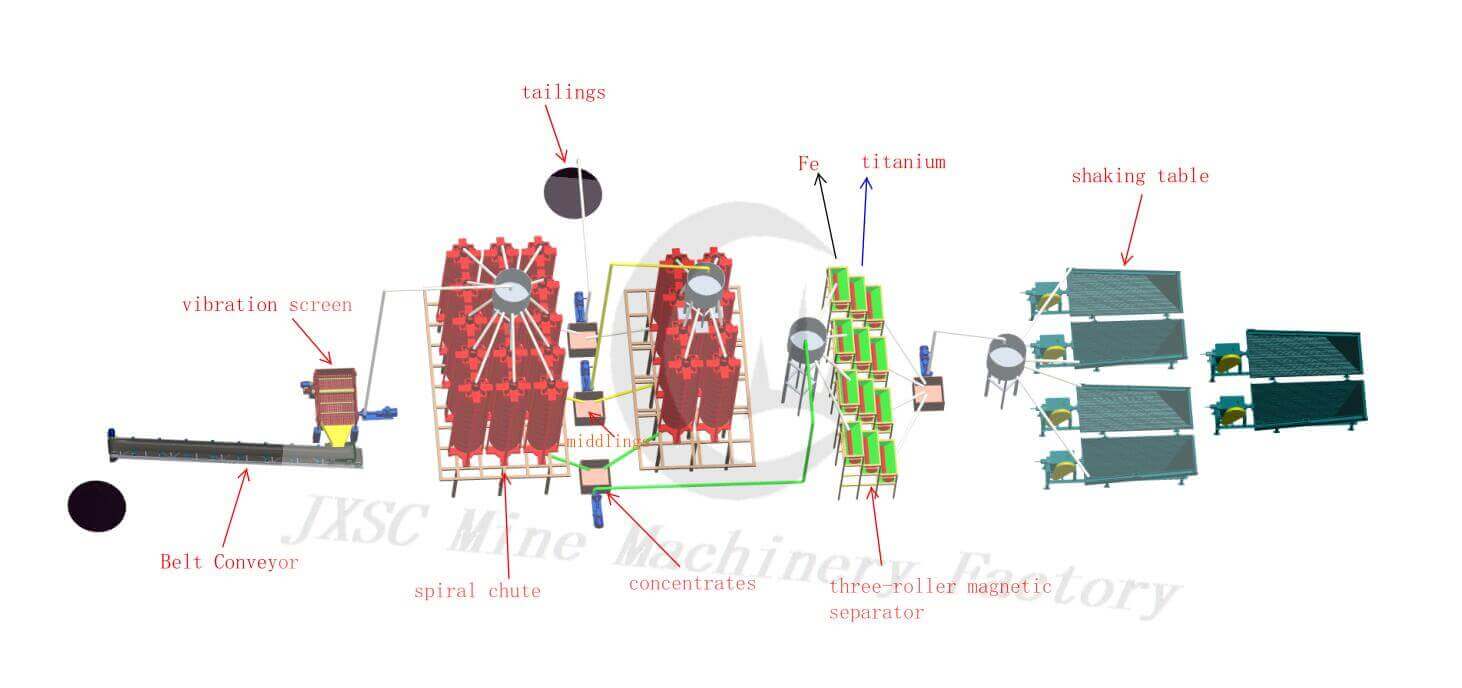

The gravity separation method removes the gangue minerals in the ore through jigging, spiral chute, shaking table, and other equipment after the ilmenite is crushed. It is mainly suitable for coarse-grained ilmenite.

2. Ilmenite Magnetic Separation

Since ilmenite has weak magnetism, magnetic separation can separate it from non-magnetic minerals. If the magnetic field strength is insufficient during magnetic separation, part of the ilmenite minerals will be discarded, decreasing resource utilization efficiency. Therefore, the magnetic field strength is a critical factor in the magnetic separation process of ilmenite.

Ilmenite mainly exists as a complex solid solution in the deposit, quickly producing ilmenite flakes with a higher magnetization coefficient. The magnetization difference with the gangue increases, making it easy for magnetic separation. Some ilmenite sand ores contain a large amount of impurities and sludge. After primary grinding, weak magnetic separation can be used to separate the iron ore. Then, strong magnetic separation can be used to separate the titanium ore to improve the recovery of the ore.

3. Ilmenite Flotation

The flotation method is a commonly used separation method for ilmenite, which can be divided into the conventional flotation method, flocculation flotation method, agglomeration flotation method, and carrier flotation method.

-

Conventional flotation

Conventional ilmenite beneficiation methods generally use oleic acid, oxidized paraffin soap, tar oil, etc., as ilmenite collectors. The combination and ratio of collectors can be determined based on different mineral compositions. For example, some ores contain both ilmenite and titanium pyroxene. The two minerals have similar floatability and can be separated using new collectors. , improve the ore grade.

-

Flocculation flotation

The ilmenite flocculation and flotation method can also be divided into selective flocculation and flotation methods and hydrophobic flocculation and flotation methods, mainly used for ilmenite with finer particle sizes. The selective flocculation and flotation method condenses one mineral and then gradually separates it into a slurry containing two or more minerals. The hydrophobic flocculation and flotation method uses the mutual hydrophobic interaction of hydrophobic mineral particles to agglomerate them into separate clusters.

-

Agglomeration flotation

The ilmenite agglomeration flotation method uses a collector adsorbed on the surface of ilmenite, which makes the ilmenite particles hydrophobic and uses the capillary attraction of the bridging liquid to agglomerate the ore particles, thereby achieving ilmenite flotation. It is suitable for particle size Finer ilmenite. When using this flotation method, you need to pay attention to the use of collectors and the intensity of stirring. These two factors have a direct impact on the recovery of ilmenite.

4. Combined Ilmenite Separation

Ilmenite often contains various minerals and impurities, such as rutile, titanite, etc. In order to improve the mineral grade and recovery rate and achieve comprehensive utilization of minerals, the combined beneficiation method has better results than the single beneficiation method. Currently commonly used combined ilmenite beneficiation methods include: magnetic separation – flotation method; gravity separation – flotation method; magnetic separation – gravity separation method; gravity separation – magnetic separation- flotation – electrical separation method

-

Magnetic separation – flotation

This mineral processing method is to first magnetically separate the ilmenite to remove some useless gangue minerals and then float the magnetically separated concentrate to improve the ore grade and recovery rate of the ilmenite concentrate.

-

Gravity separation – flotation

The gravity separation-flotation has a good selection effect for ilmenite with a raw ore grade of less than 6%. It can also separate the sulfur in the ilmenite and improve the utilization rate of ilmenite resources.

-

Magnetic separation – gravity separation

The combination of magnetic separation and gravity separation can reduce the production cost of ilmenite beneficiation, improve the concentrate grade and recovery rate of ilmenite, and improve production efficiency.

-

Gravity separation – magnetic separation – flotation – electrical separation

Suppose the ilmenite gangue mineral contains titanium pyroxene, plagioclase, sulfide minerals, etc.. In that case, the plagioclase can be removed first through gravity separation. The flotation method can be used for desulfurization, and titanium pyroxene can be removed using the electric separation method. Improving the grade and utilization of ilmenite is a better solution for low-grade ilmenite.

The above is the beneficiation method of ilmenite. In actual production, due to the complex composition of ilmenite, we must rely on more than experience to determine the process flow. It is recommended to analyze the mineral composition and properties of the ore through mineral processing tests and formulate scientific and reasonable mineral processing plans based on the test results.

JXSC Mine Machinery Factory is renowned and highly respected in manufacturing ilmenite processing and mining equipment. With a reputation built on expertise and a commitment to excellence, we have established ourselves as a professional designer specializing in the processing of ilmenite and a trusted mining equipment manufacturer. Our dedication to innovation and state-of-the-art technology ensures that we stay at the forefront of the industry, offering cutting-edge solutions for extracting, refining, and processing ilmenite ore. With a focus on quality, efficiency, and sustainability, JXSC plays a pivotal role in meeting the global demand for titanium and other valuable minerals, contributing to the advancement of various industries and the growth of the mining sector.

LATEST PRODUCTS

-

Tubular Screw Conveyor

【Capacity】6-50 m3/h 【Procesible Material】 …

-

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

-

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…