Introduction

XMB three-roll four-tank rod mill has the advantages of compact structure, easy to use, small size, and lightweight.

It is commonly used in the laboratory for supporting the use of FD Series Single cell flotation machine(volumes of 0.5, 0.75, 1.0, 1.5 liters) and FG hanging slot flotation machine(volume of 0.02, 0.06, 0.1, 0.14 liters or processing capacity of 5, 15, 25, 35 grams) or another flotation machine with corresponding specifications, as well as other equipment. It is an ideal support laboratory grinding equipment.

Application

Technical Parameter

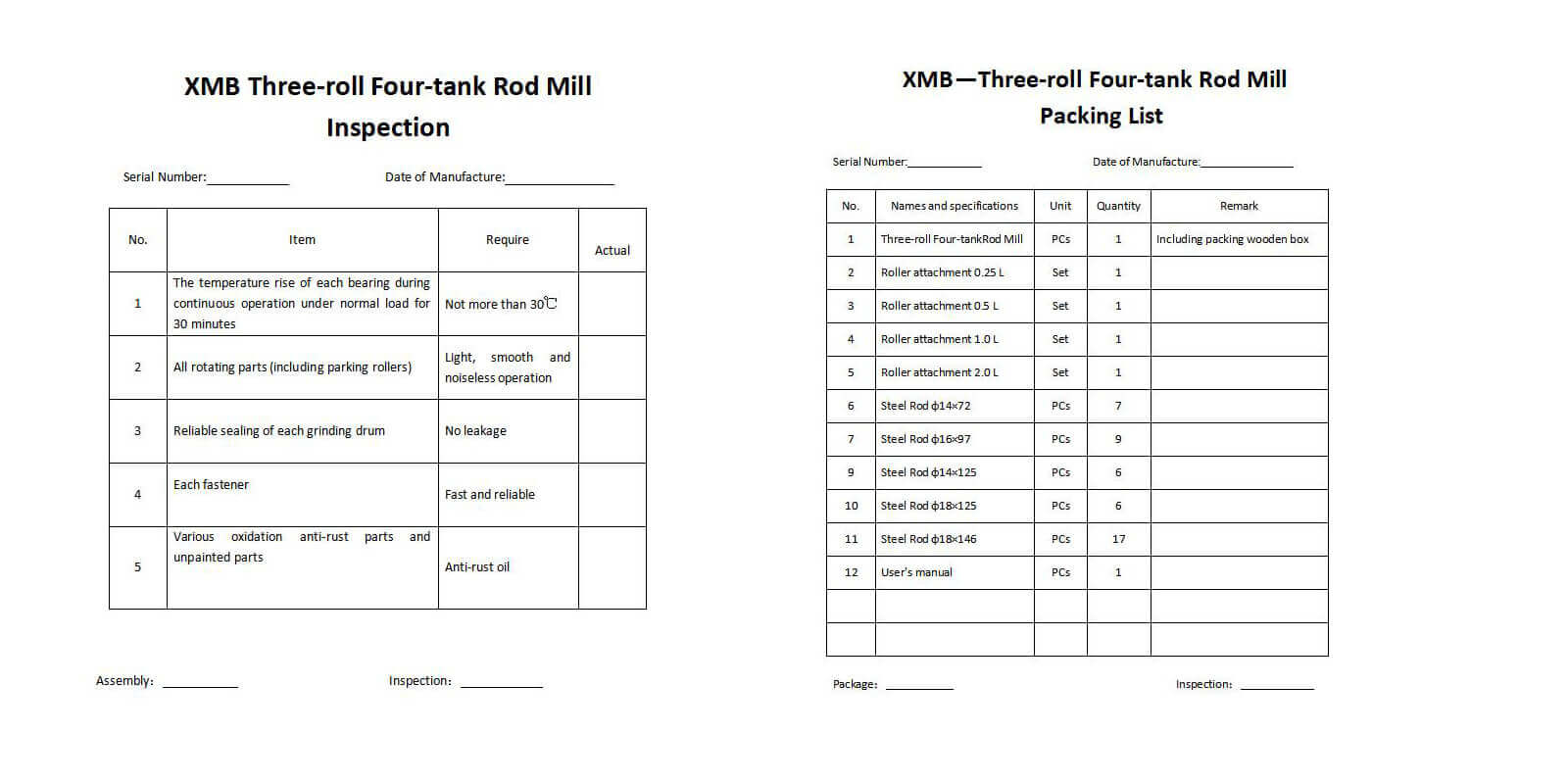

| No. | Item | Specification | Unit | ||||||

| 1 | Grinding Cylinder | Volume | 0.25 | 0.5 | 1 | 2 | L | ||

| Diameter * Length | φ65×86 | φ83×107 | Φ95×137 | φ132×162 | ㎜ | ||||

| 2 | Maximum Magnetic Intensity | 50 | 100 | 280 | 400 | g | |||

| 3 | Feeding Size | -0.5 | -0.5 | -1 | -2 | ㎜ | |||

| 4 | Output Size | -0.074 | -0.074 | -0.074 | -0.074 | ㎜ | |||

| 5 | Steel Rod | Diameter * Length | φ10×72 | φ12×95 | φ14×125φ18×125 | φ18×146 | ㎜ | ||

| Quantity | 7 | 9 | 6/cylinder | 17 | pcs | ||||

| Weight | 0.62 | 1.5 | 2.6 | 5.22 | ㎏ | ||||

| 6 | Steel Ball | Diameter | φ12 | φ15 | φ20 | φ25 | ㎜ | ||

| Quantity | 40 | 40 | 40 | 40 | |||||

| 7 | Drive Roller Speed | 0—400 | r/min | ||||||

| 8 | Motor | Model | Y90S-6 | ||||||

| Power | 0.75 | kW | |||||||

| Rotating speed | 1000 | r/min | |||||||

| 9 | Dimension | (L*W*H) 900×540×950 | ㎜ | ||||||

| 10 | Weight | 125 | ㎏ | ||||||

Note:

- In order to ensure the grinding drum operates under the best parameters when grinding, it must work according to the steel bar ratio system recommended in the table, otherwise, the grinding efficiency will be significantly reduced, and even the normal grinding conditions will be damaged.

- Users can also choose through the system test.

Structure & Maintenance

Structure

XMB-70 type three-roll four cylinder rod mill consists of a main engine and 4 different specifications of grinding drums.

Four different specifications of grinding rollers can be placed on the rubber rollers arranged in parallel on the upper part of the main machine individually or at the same time according to the needs of use. The grinding drum is placed on the roller, and it rolls on the main and driven rollers due to the action of friction. The steel rod in the grinding drum is impacted in the cylinder wall, and the grinding is carried out by grinding and stripping.

Maintenance

The distance between the main and driven rollers can be adjusted according to the size of the selected grinding drum. When the equipment leaves the factory, the driven rollers close to the working face are installed at a larger distance, and the driven rollers away from the working face are installed at the smallest distance. position at a distance. In order to meet the requirement that several kinds of rollers grind at the same time and need to be parked separately, a pair of parking rollers covered with rubber tubes are installed between the main and driven rollers. When the time is required, pull the parking handle out of the positioning plate from the axis of the handle, and then move it into the positioning hole of the positioning plate on the side that needs to stop working, so that the roller can lift the grinding cylinder for subsequent operations. At this time, the grinding work on the other side is still carried out as usual and is not affected. When grinding on both sides is required at the same time, the handle can be inserted into the positioning hole in the middle of the positioning plate.

The electrical equipment of equipment has been installed and has undergone a comprehensive inspection and commissioning according to the factory requirements. After the user receives the equipment, remove the packaging and grease, connect the power supply and ground wire, and then it can be used.

All rotating parts of the equipment, except for the rolling bearing, use rolling bearings and do not need to be refueled frequently. Together with the rolling bearings on both sides of the motor, the oil can be changed once a year, or additional oil can be added according to the usage. It is recommended not to use sodium-based grease, so as to avoid the saponification failure of the grease after the flushing water enters. Both ends of the payroller are made of nylon and molybdenum disulfide with sufficient self-lubricating capacity, and no additional lubricant is required.

Operation

- When starting to work, mix the mineral sample with water and put it into the grinding drum to cover it;

- Open the upper cover of the equipment, put the grinding drum in place, and put down the cover;

- Set the grinding time, open the timer cover, and set the required time;

- When the switch is turned on, the motor drives the main roller to rotate, and the grinding roller rolls on the main roller and the secondary roller due to the action of friction so that the grinding roller grinds the ore.

Installation and Use

Installation

- The machine does not need to set up another foundation. It can be directly placed on a common workbench or platform. After adjusting the level with the adjustable supports on the four corners of the machine, you can start to clean the packaging grease, connect the power supply and ground wire, and check the operation. direction, so that the driving roller rotates in the direction of the operating surface.

- Use waste materials for cleaning operation until the cylinder wall and steel rod is cleaned up.

- Fill the cylinder with lime water for rust prevention, cover and lock the cover, and store it in the box for future use.

Use

- Take out the grinding drum, put it on the roller and then drive, grind off the rust on the steel rod and the cylinder wall, then stop, pour out the lime water for rust prevention, and rinse the steel rod and the cylinder wall.

- Add water ore and chemicals in turn, close the feeder, put the drum on the roller, and then start grinding.

- Stop the machine after grinding to the specified time, remove the drum, open the cover, pour the pulp into the basin, and wash the steel rod and the wall of the cylinder, and then the next operation can be carried out.

- After use, fill it with lime water for rust prevention, cover the lid, and put it in the box for future use. Wipe all parts of the machine with cotton yarn or a rag, cut off the power supply, and cover the machine until the next use.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…