Copper Ore Description

Copper ore refers to the general term of available natural mineral aggregates containing copper. Copper ore is generally an aggregate composed of copper sulfide or oxide and other minerals, which reacts with sulfuric acid to produce blue-green copper sulfate. The industrial minerals of copper include natural copper, chalcopyrite, chalcocite, tetrahedrite, chalcocite, malachite, etc. More than 280 kinds of copper-bearing minerals have been found, of which only 16 are the main ones. Chalcopyrite (a compound of copper, sulfur, and iron) is the main mine in China, followed by chalcocite and bornite.

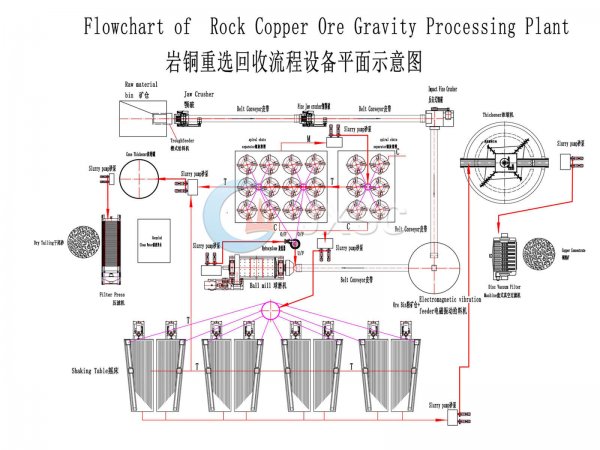

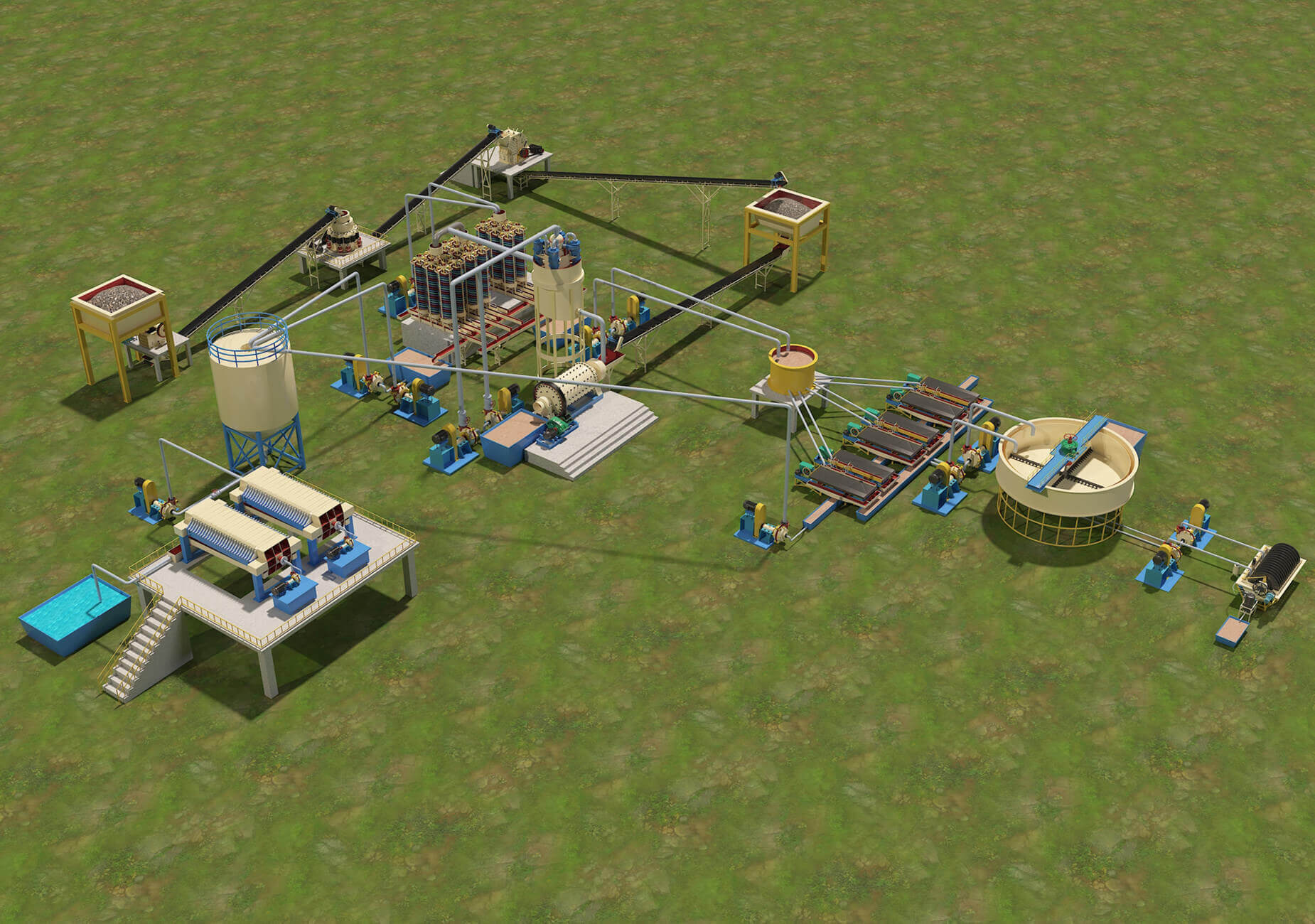

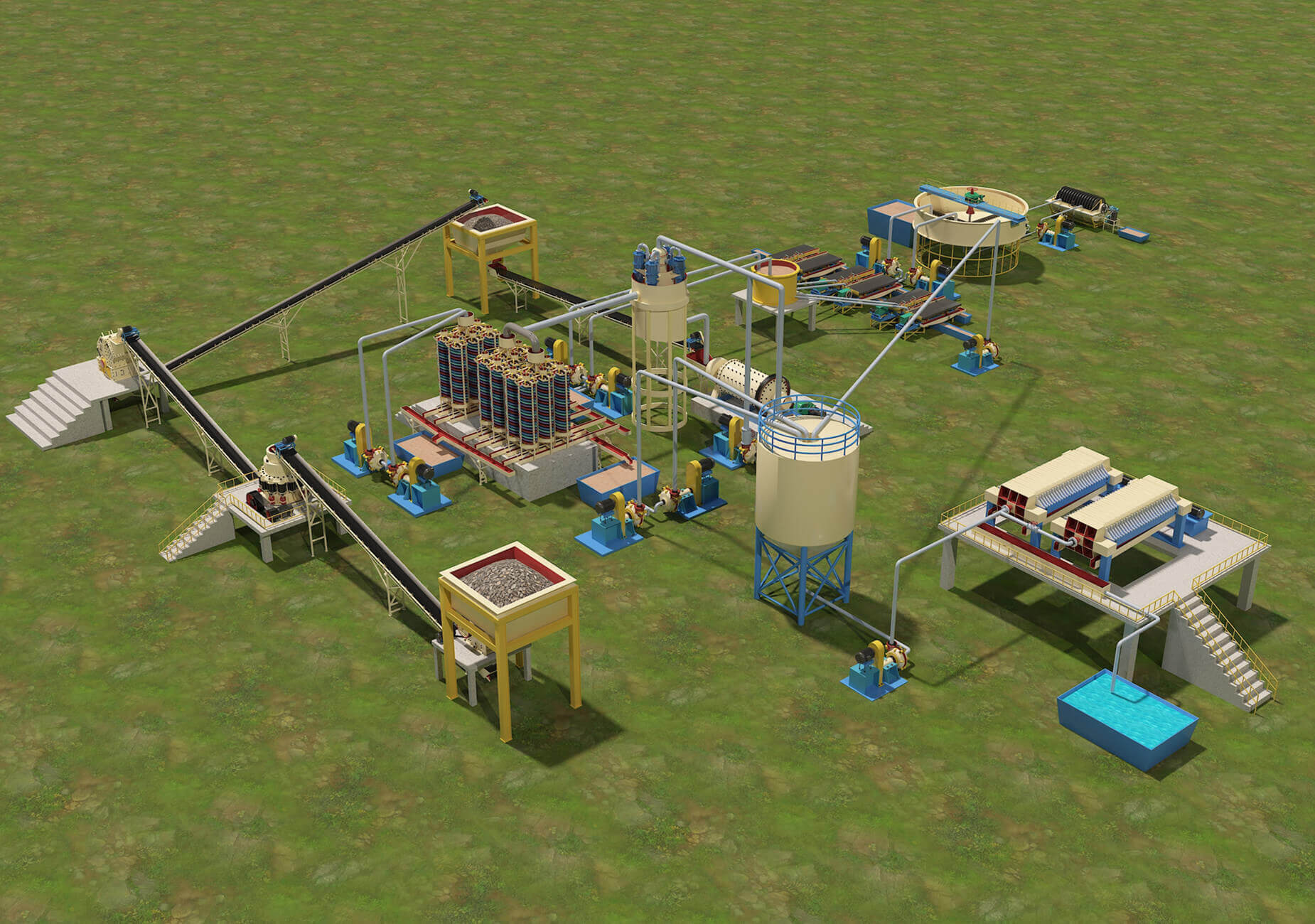

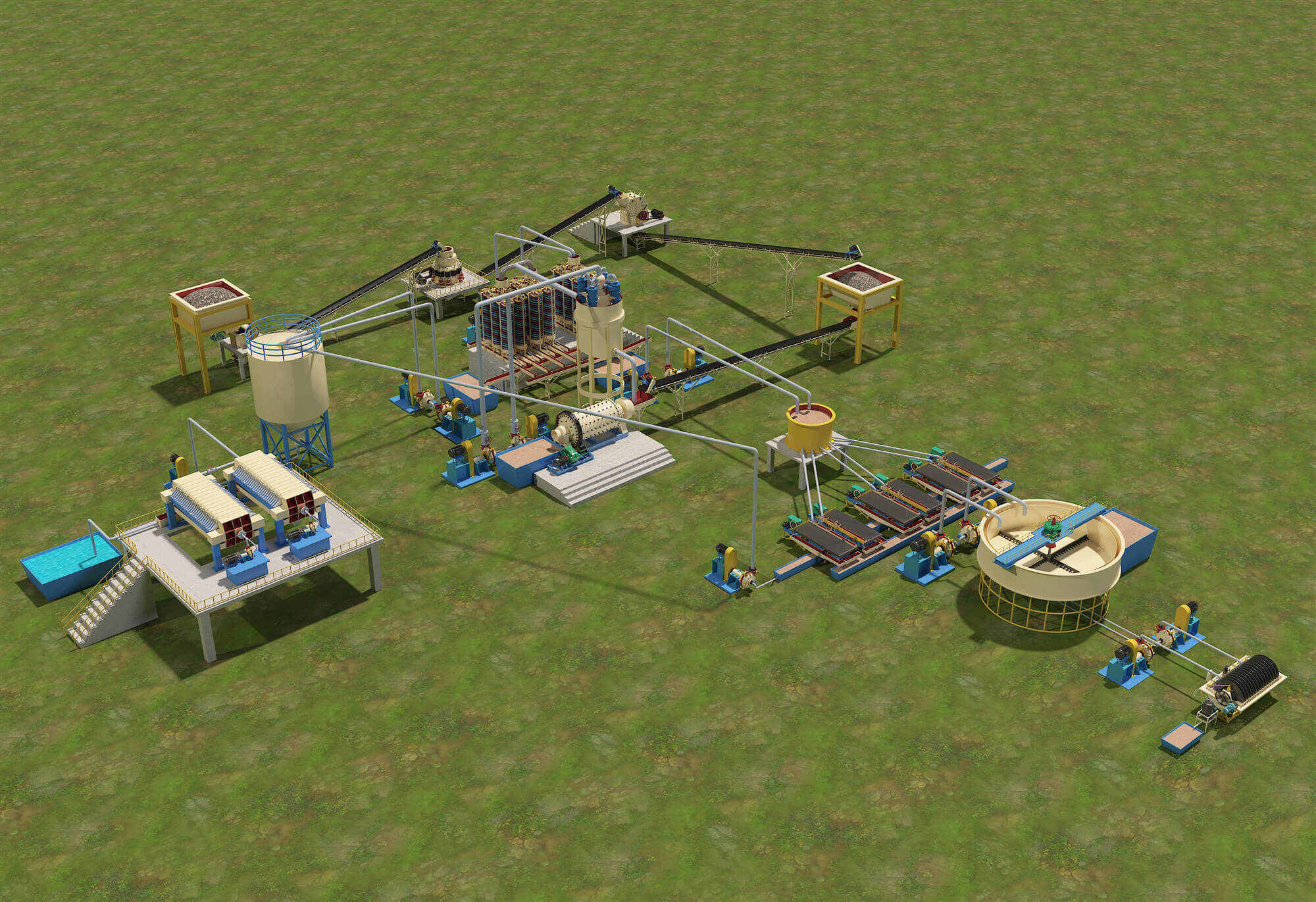

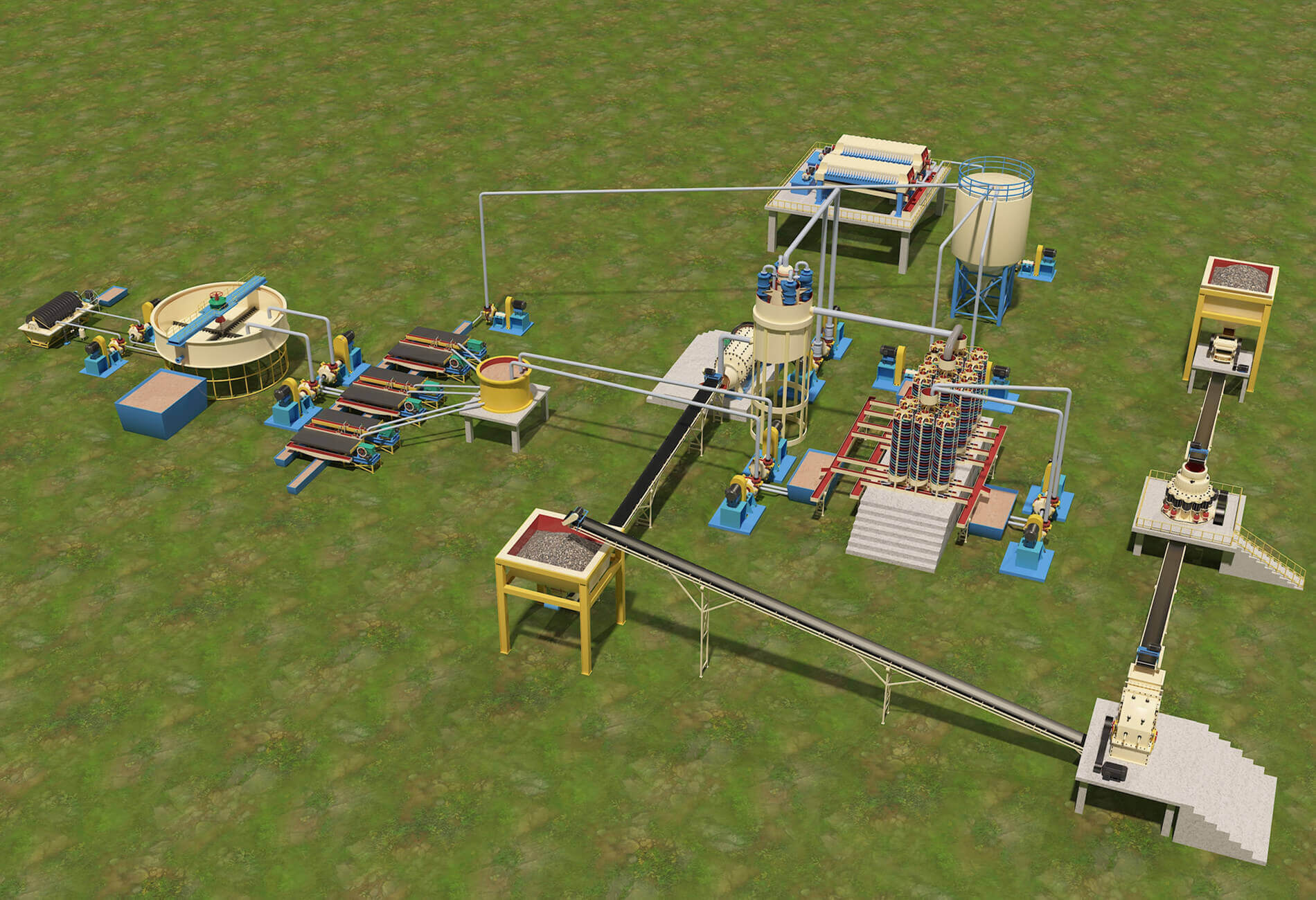

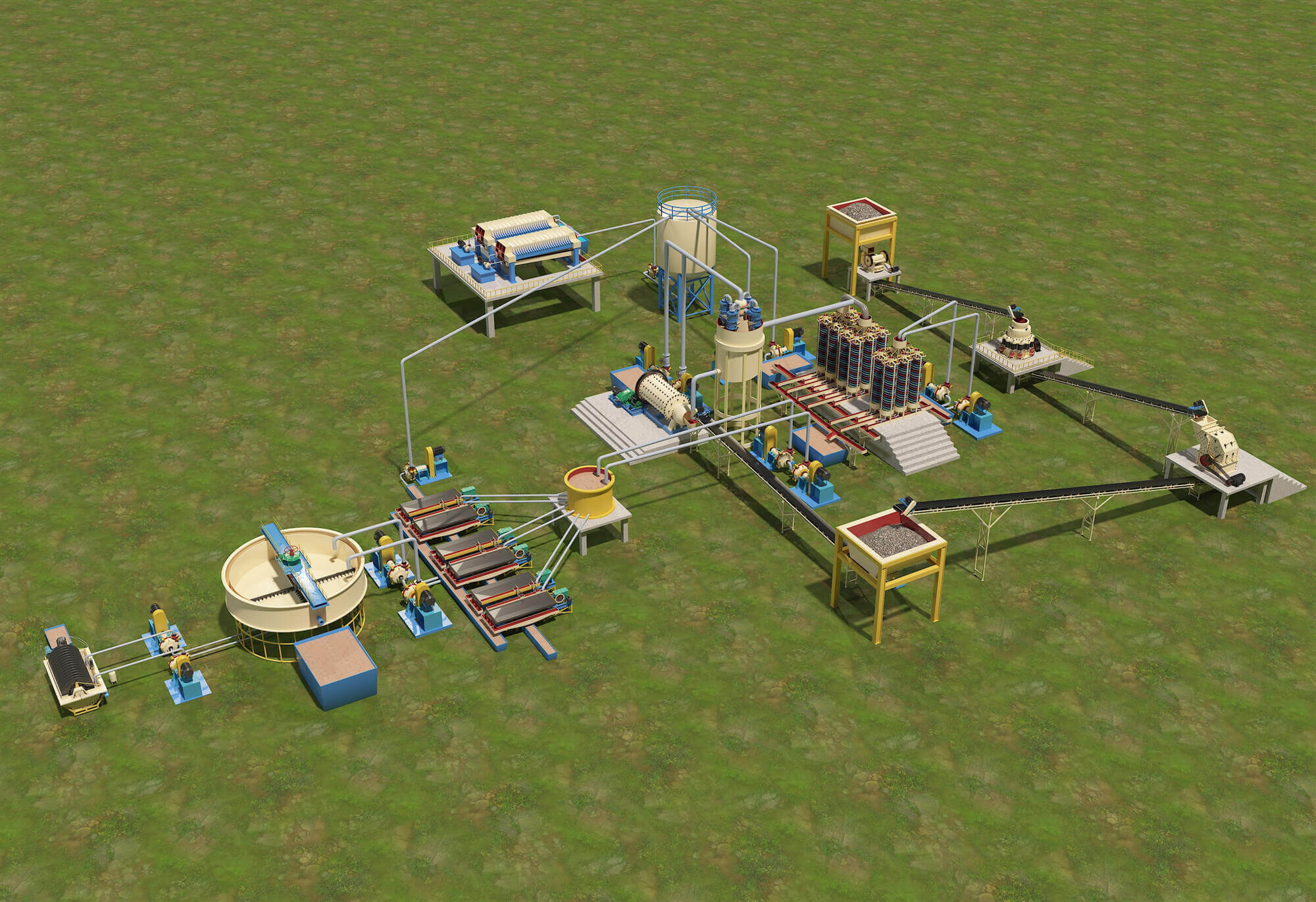

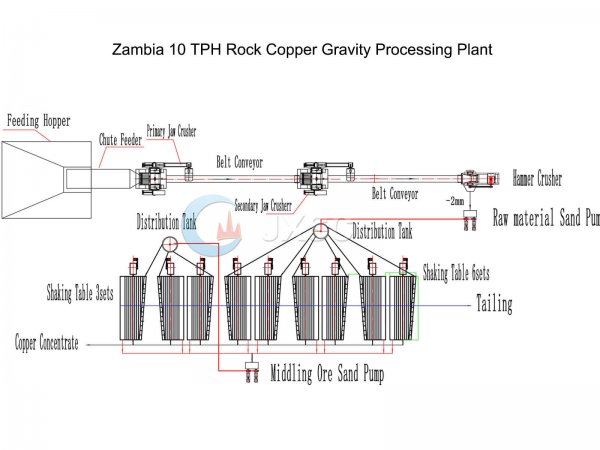

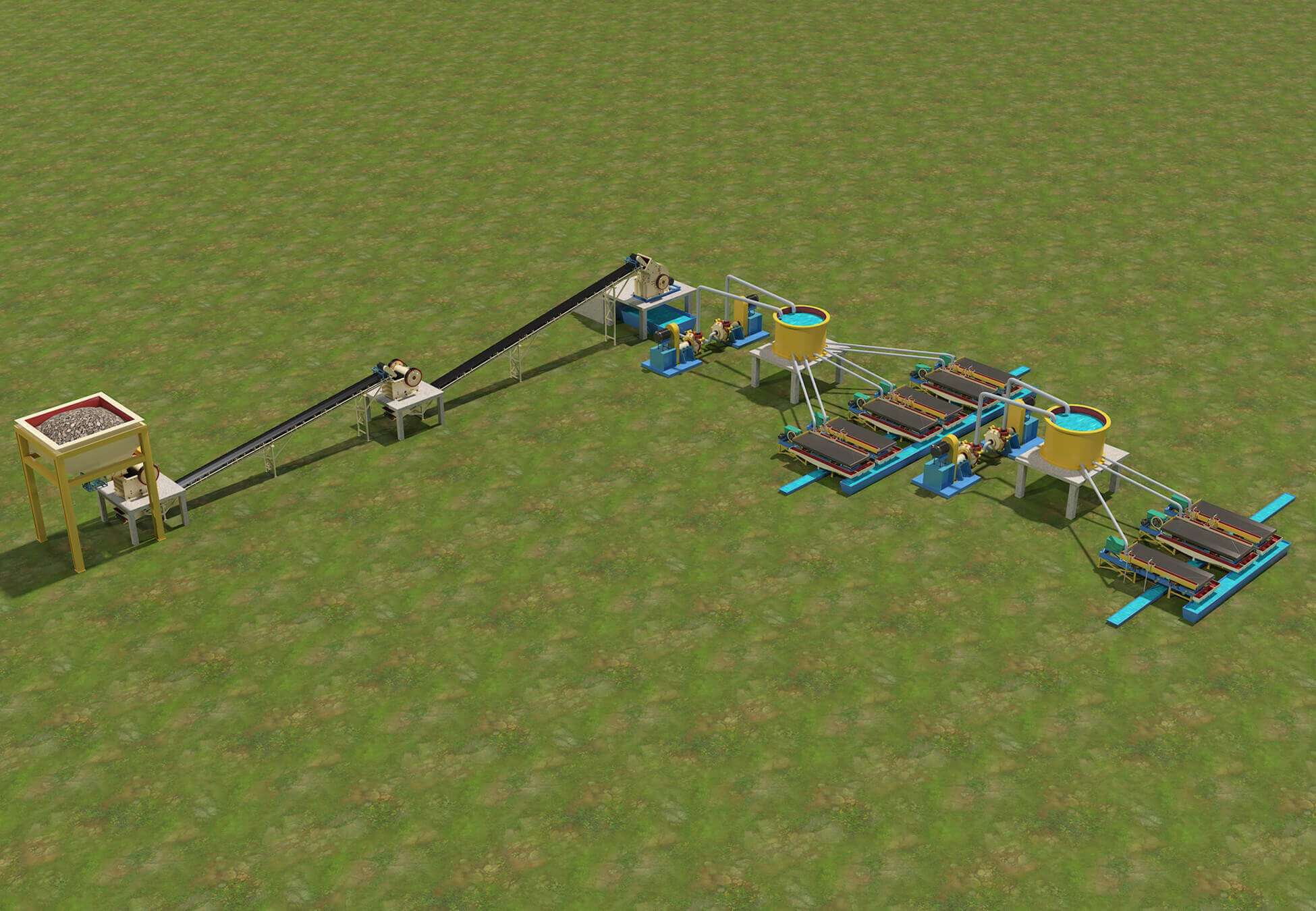

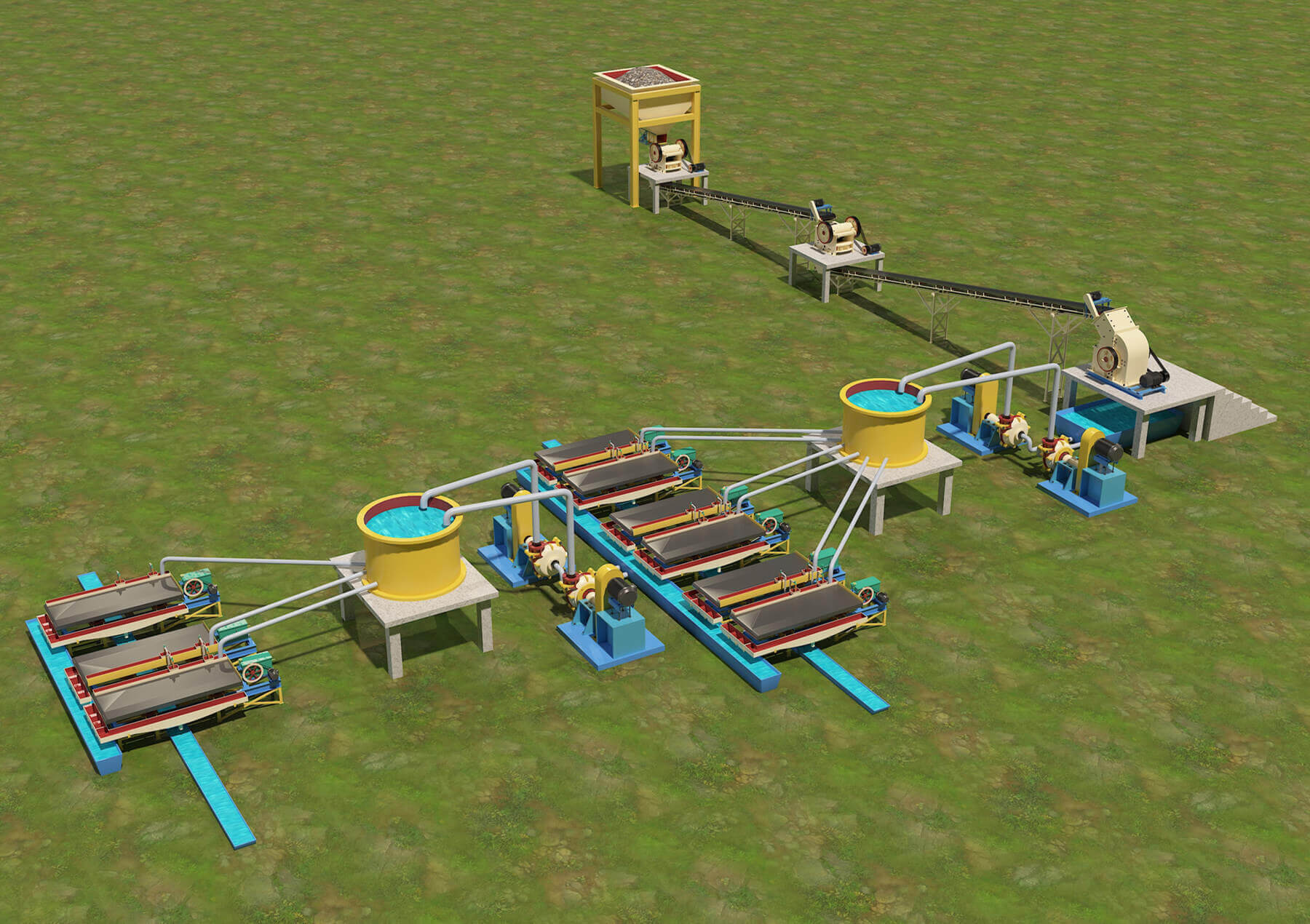

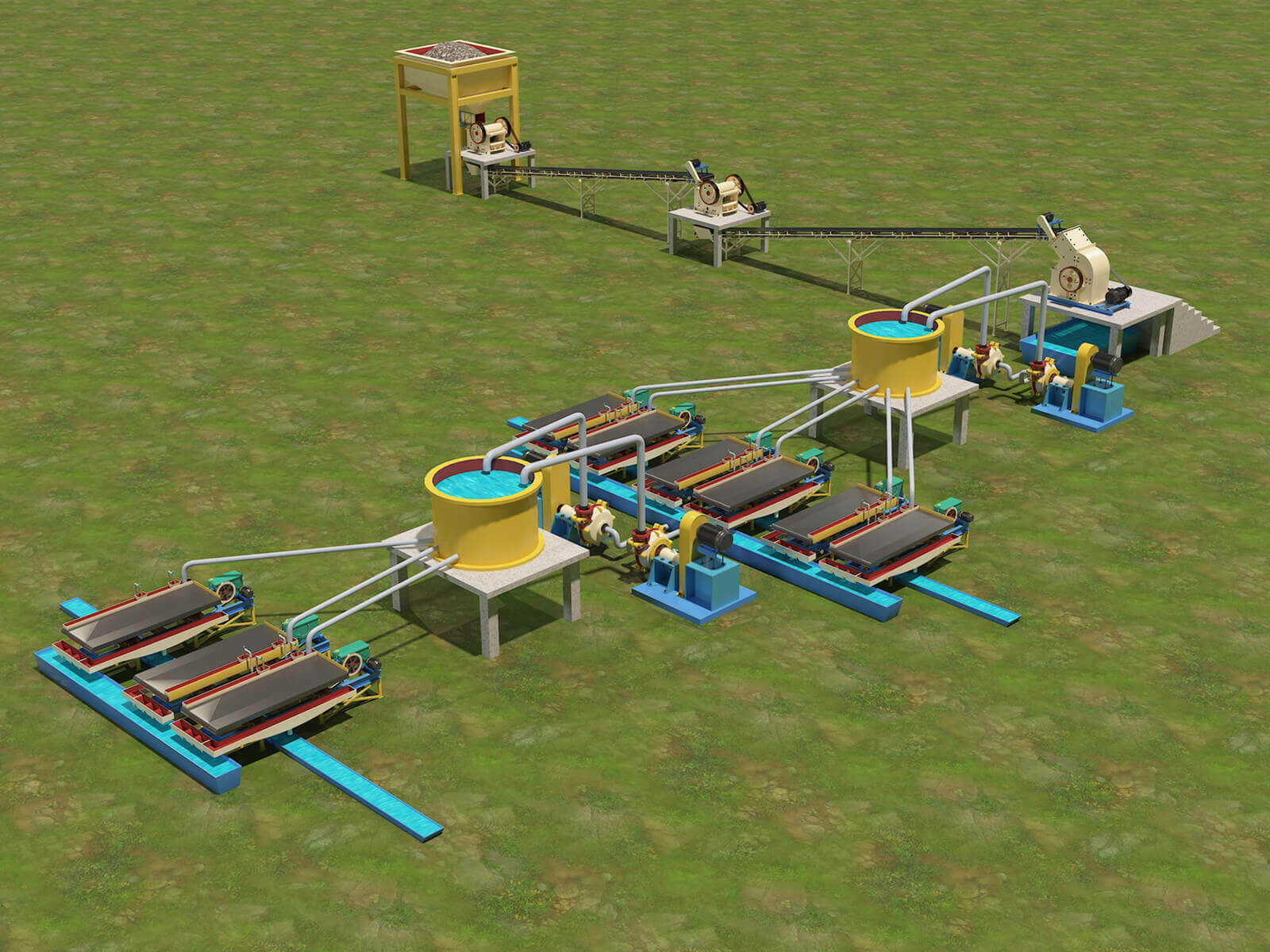

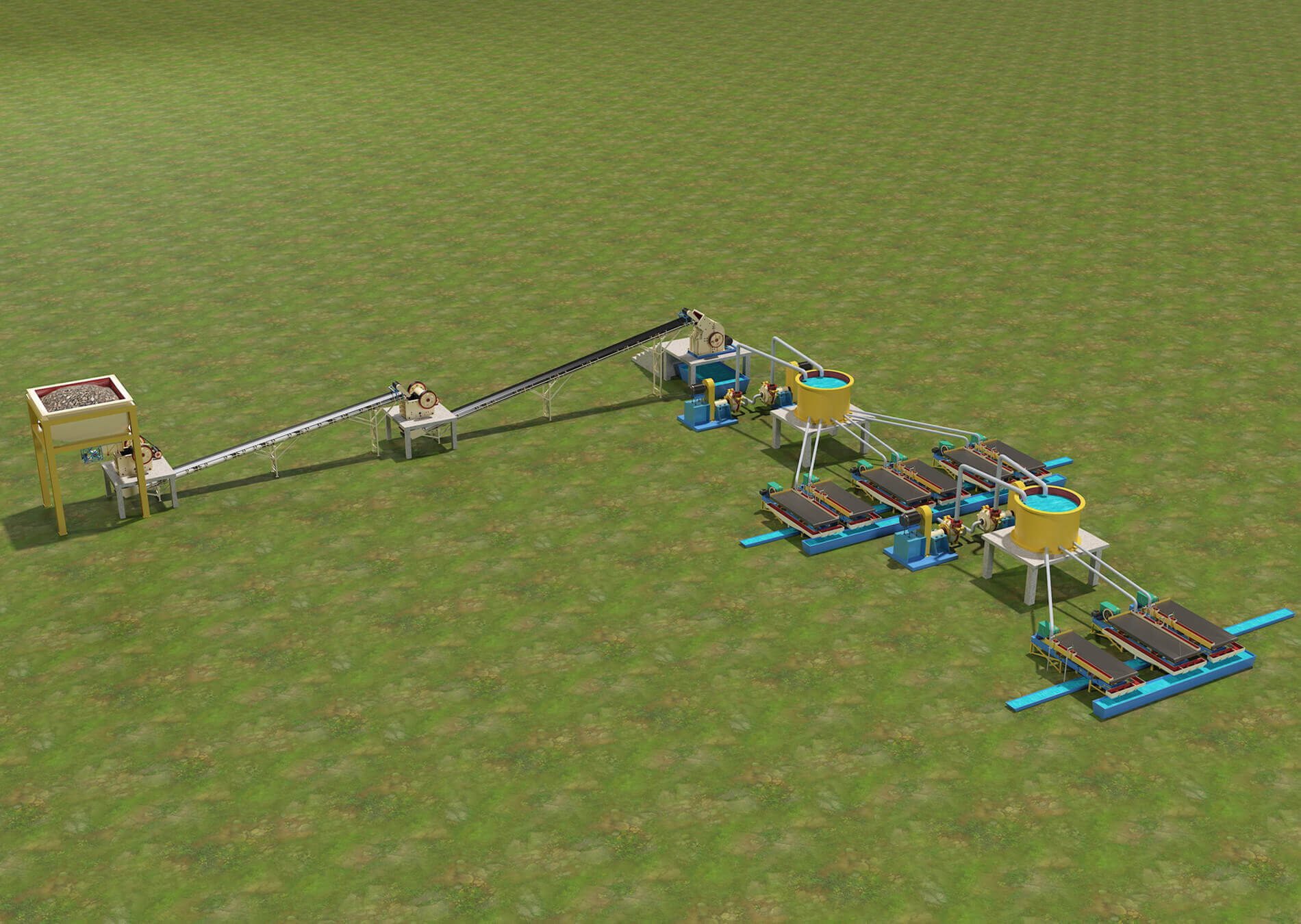

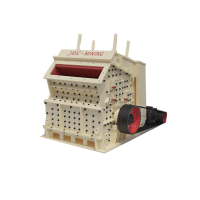

The world’s copper resources are mainly concentrated in Chile, Australia, Peru, the United States, Mexico, Russia, and other countries. Chile is the country with the richest copper resources in the world. Refer to copper ore mining, JXSC Mine Machinery Factory supplies follow solutions for your reference.