Diamond

Diamond deposits are divided into primary ore and placer. The primary ore is diamond existing in host rock. The placer is separated from the host rock under the action of external forces such as weathering and erosion and water impact, and then the diamond deposits are mostly Sandy.

Diamonds are shallow from the ground. Generally, open-pit mining is adopted, and then they are excavated underground in circles to facilitate vehicle transportation. If the diamond is deep, it is drilled vertically on the surface and mined underground.

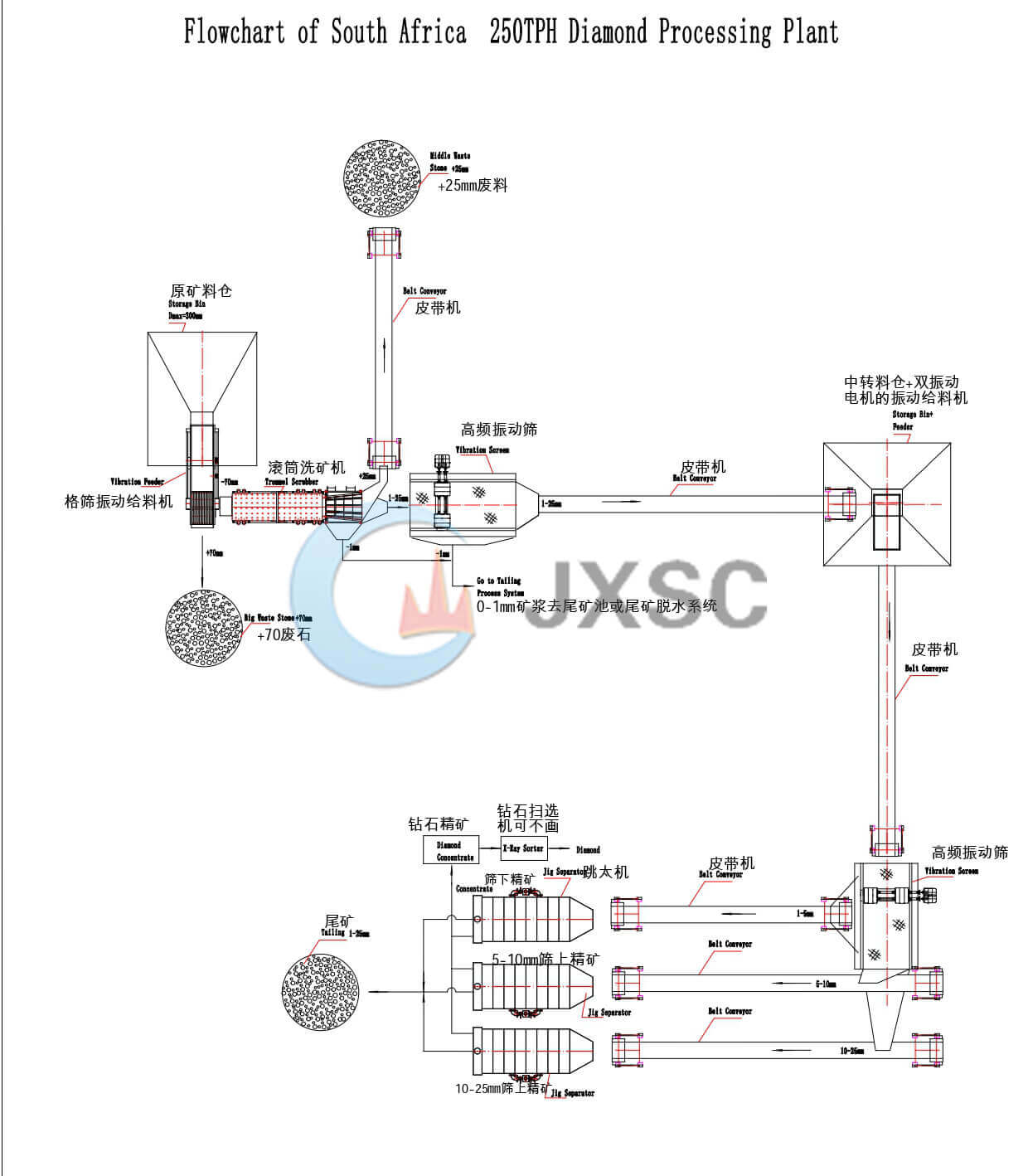

Diamond mining requires crushing, screening, ore washing, grinding, hydraulic classification, and other processes to separate and sort diamonds from the host rock, which is similar to the mining process of other gem mines.

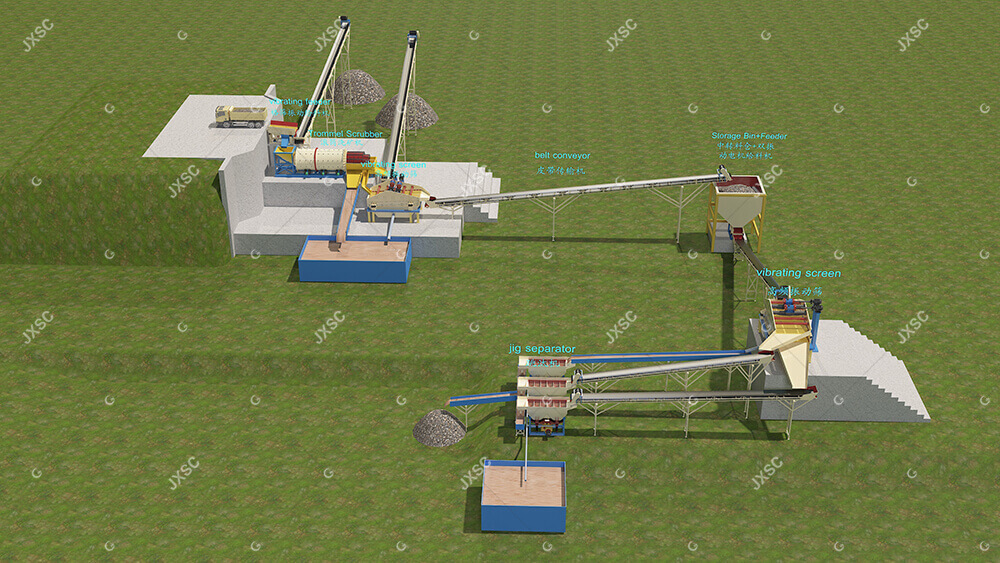

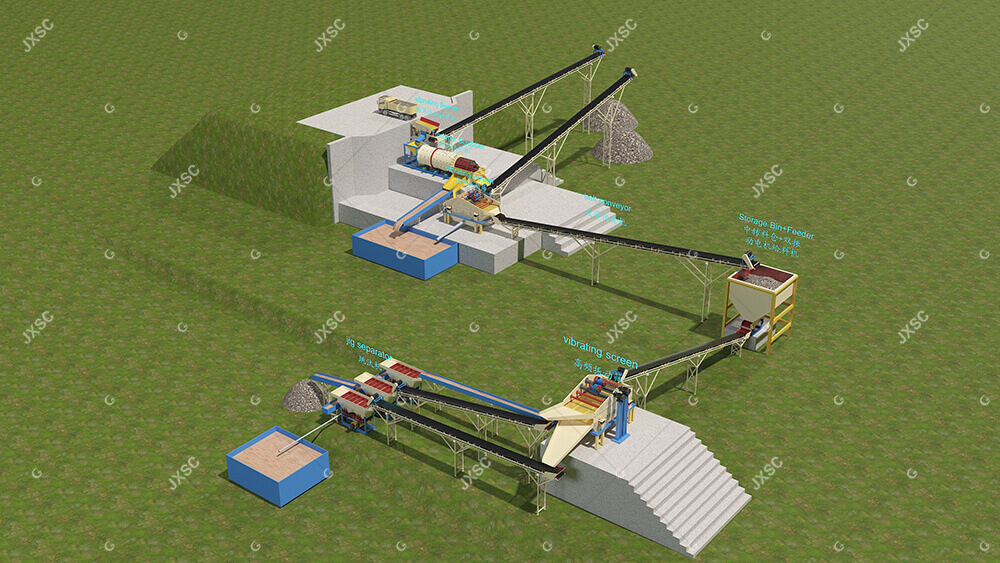

This setup is a 100tph complete alluvial diamond wash plant, the raw material is 0-250mm alluvial diamond ore with sticky clay, the diamond size is around 5-20mm. It is configured with vibrating feeder DN3896 with gap 75mm grizzly bar, one set swing feeder under the bin, JXSC-1500 trommel scrubber, one set single layer high-frequency vibration screen JXSC-1860, one set three layers high-frequency vibration screen JXSC-1860,3 sets jig separator, 6 sets belt conveyors.

- The truck unloads the 0-250mm diamond ore into the vibrating feeder; the +75mm scrap will be separated by the vibrating feeder grizzly bar and transferred by 1st conveyor to the first stockpile.

- The vibrating feeder feeds the -75mm ores evenly to the trommel scrubber to wash and separate by 5mm,20mm mesh. The 0-5mm material will be sent to the tailing pool by a trough. 5-20mm material will be sent to the first vibrating screen for further cleaning and dewatering, and 20-75mm material will be sent to the second stockpile by 2nd conveyor.

- The 5-20mm washed materials after washing and dewatering will be transferred to the storage bin equipped with one small feeder under the bin.

- The materials 5-20mm will be sent to the next high-frequency vibration screen. It will be separated into 3 size ranges: 0-10mm, 10-15mm 15-20mm. Each size will be equipped with one jig concentrator to concentrate