Lepidolite Ore

Lepidolite is the most common lithium mineral and an important mineral for lithium extraction. It is a basic aluminosilicate of potassium and lithium, one of the mica minerals. Lepidolite is generally only produced in granite pegmatite, the color is purple and pink and can be light to colorless, with pearl luster, in the form of short cylinders, small flake aggregates, or large plate crystals.

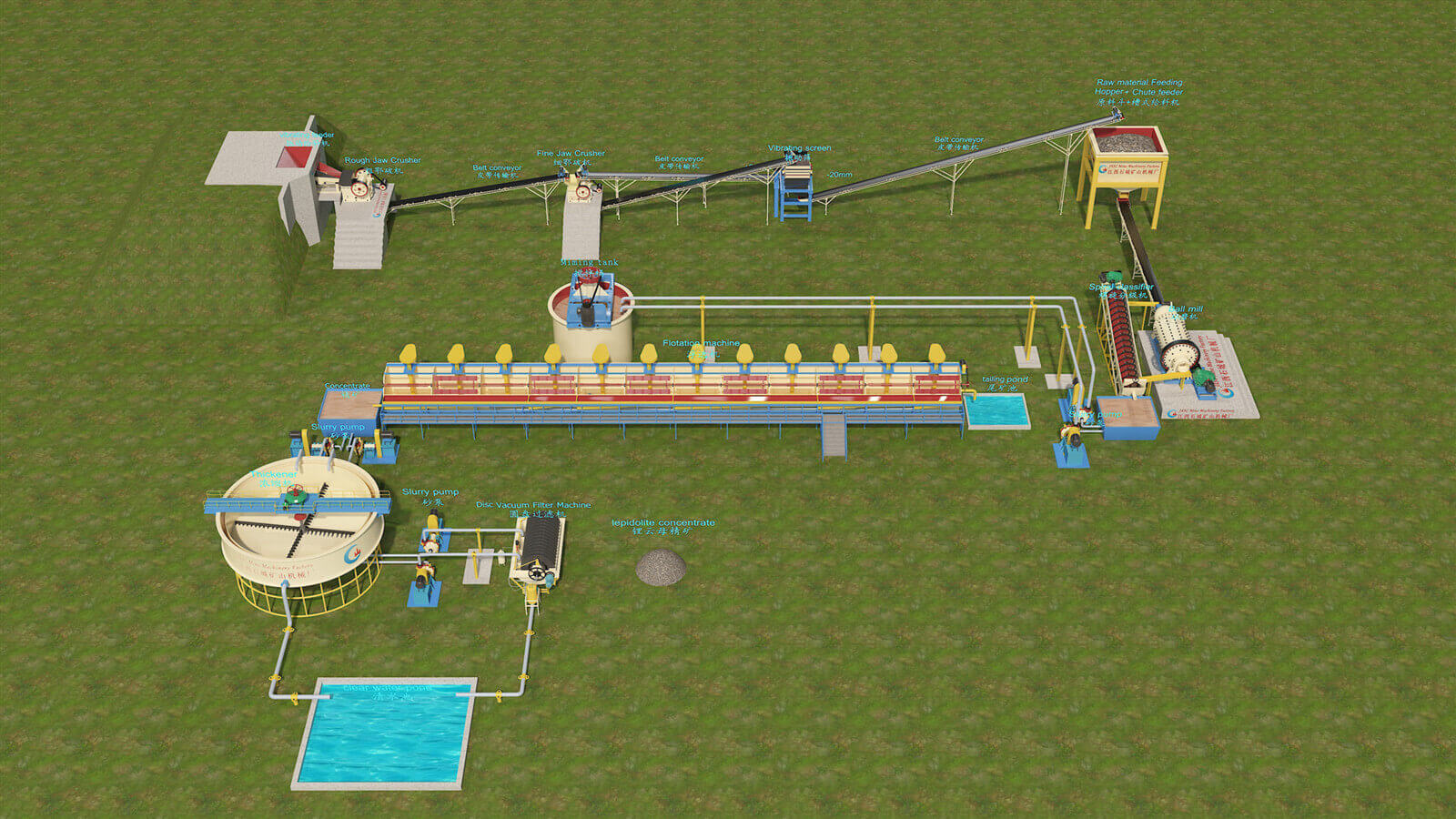

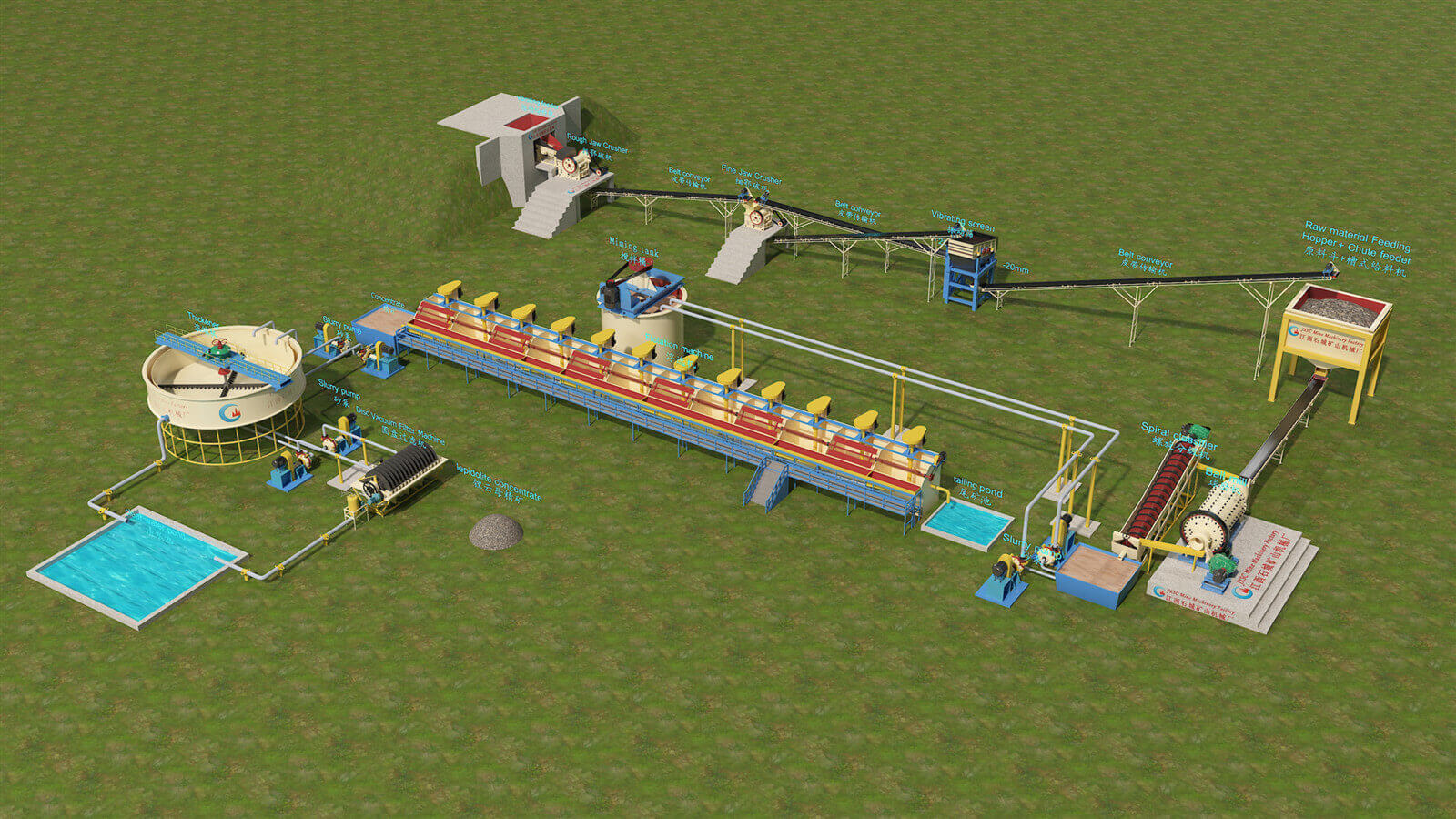

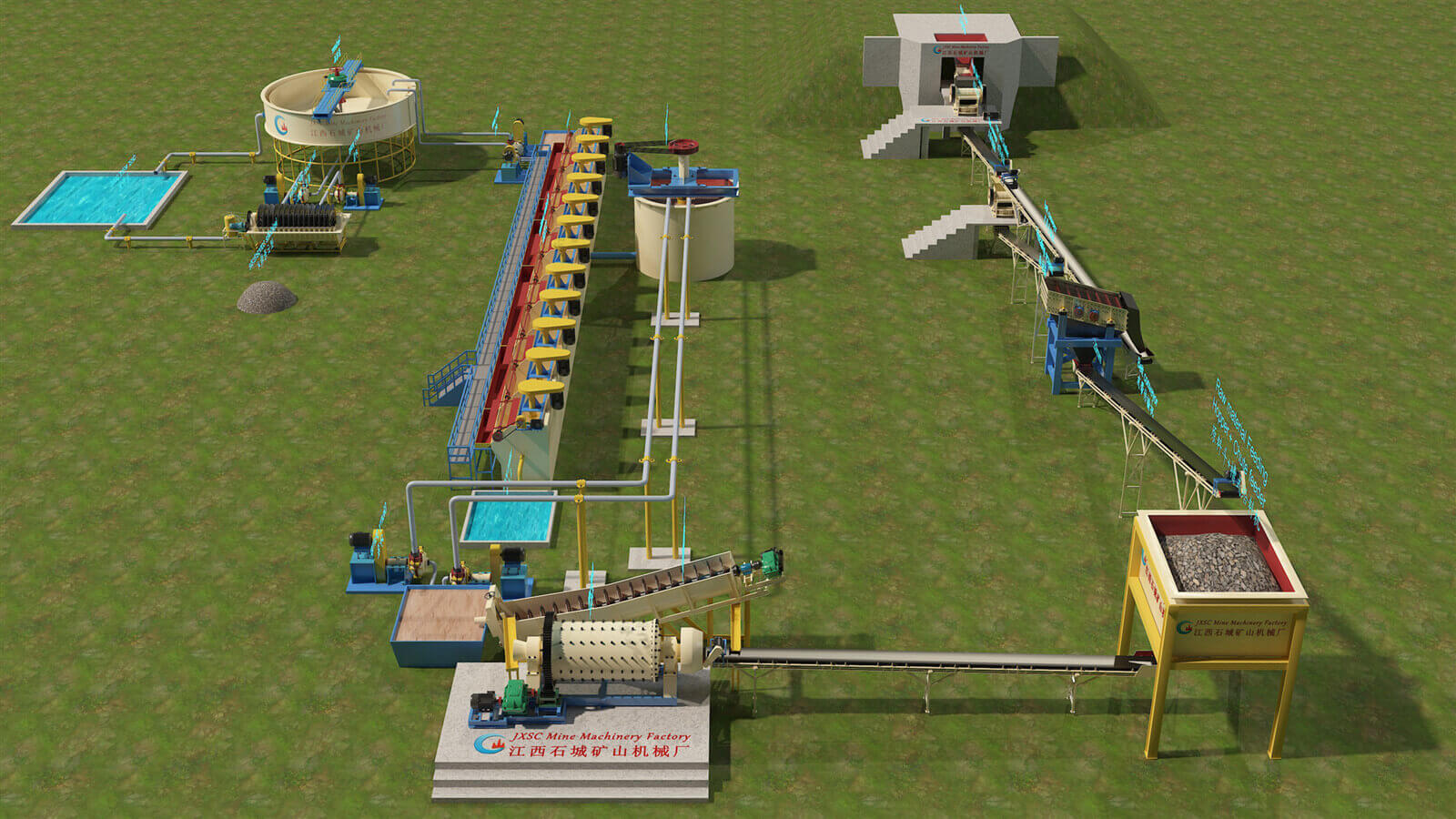

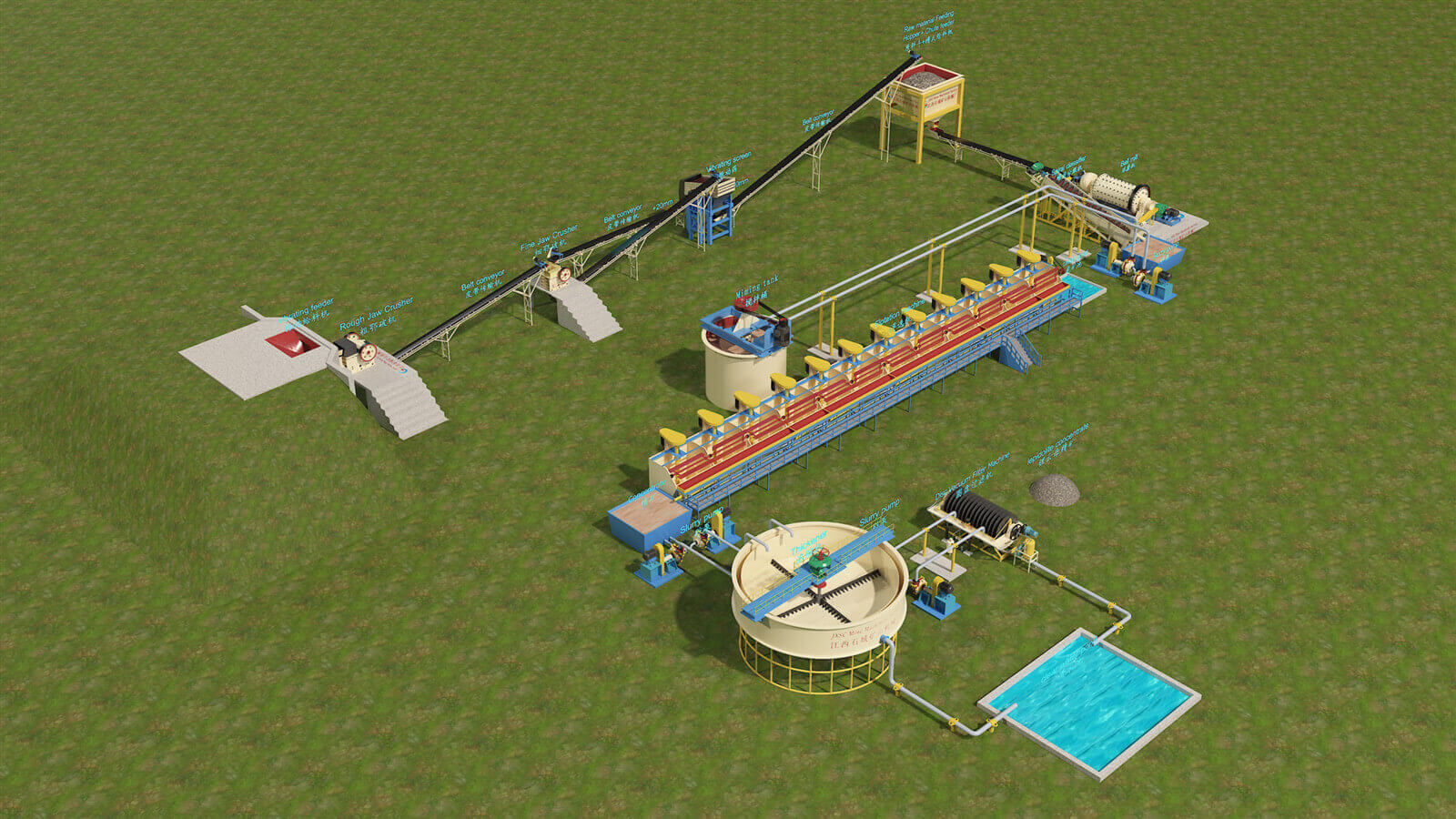

Lepidolite Flotation Process Plant

Release time:07 November 2022Lepidolite Ore Process

500T/D Lepidolite Flotation Process Plant

Lepidolite Flotation Process Plant Equipment

The equipment used in this iron ore processing plant:

- Vibrating Feeder

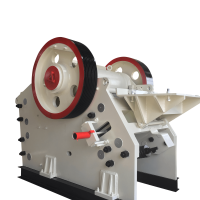

- Jaw Crusher

- Belt Conveyor

- Vibrating Screen

- Electromagnetic Feeder

- Ball Mill

- Slurry Pump

- Spiral Classifier

- Flotation Machines

- Thickener

- Disc vacuum filter machine

Lepidolite Processing Layout

This 500tpd lepidolite flotation process plant is configured with a hopper+vibration feeder, jaw crusher, fine jaw crusher, vibration screen, storage bin+electromagnetic feeder, ball mill, slurry pump, spiral classifier, flotation machines, thickener, disc vacuum filter machine.

The processing plant is as:

- The hopper+vibration feeder is for feeding the stones to the jaw crusher automatically.

- The jaw crusher is for crushing the big stones to small, then to the fine jaw crusher.

- The fine jaw crusher is for crushing the output from the jaw crusher, to make the stones into fine sands.

- The vibration screen is for sieving larger than 20mm back to the fine jaw crusher, and 0-20mm to the storage bin.

- The storage bin+electromagnetic feeder is for feeding the materials to the ball mill automatically.

- The ball mill is for grinding the fine sands to 0-1mm, combined with the spiral classifier to make sure the size of the final product to 0-0.074mm.

- The slurry pump No.1 is for transporting the overflow from the spiral classifier to the flotation machine.

- The flotation machine is for getting the lepidolite concentrate with chemicals.

- The lepidolite concentrate of the flotation machine will to the thickener and then to the disc vacuum filter machine to get dry final products.

Notes:

- The capacity for this crushing plant can be customized as per request such as 10tph, 50tph, 100tph, etc.

- The layout of the machines just for your reference will need to revise based on the mine condition.

We are a professional ore mining solution supplier in China. If you need mineral ores solutions, please click here to ask for free flow design.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.